A nitrogen-doped 3D porous carbon material and a preparation method and application thereof

A technology of porous carbon materials and nitrogen doping, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high price and complicated process, and achieve the effect of simple method, good activity and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a nitrogen-doped 3D porous carbon material by using cellulase pretreatment, including the following steps:

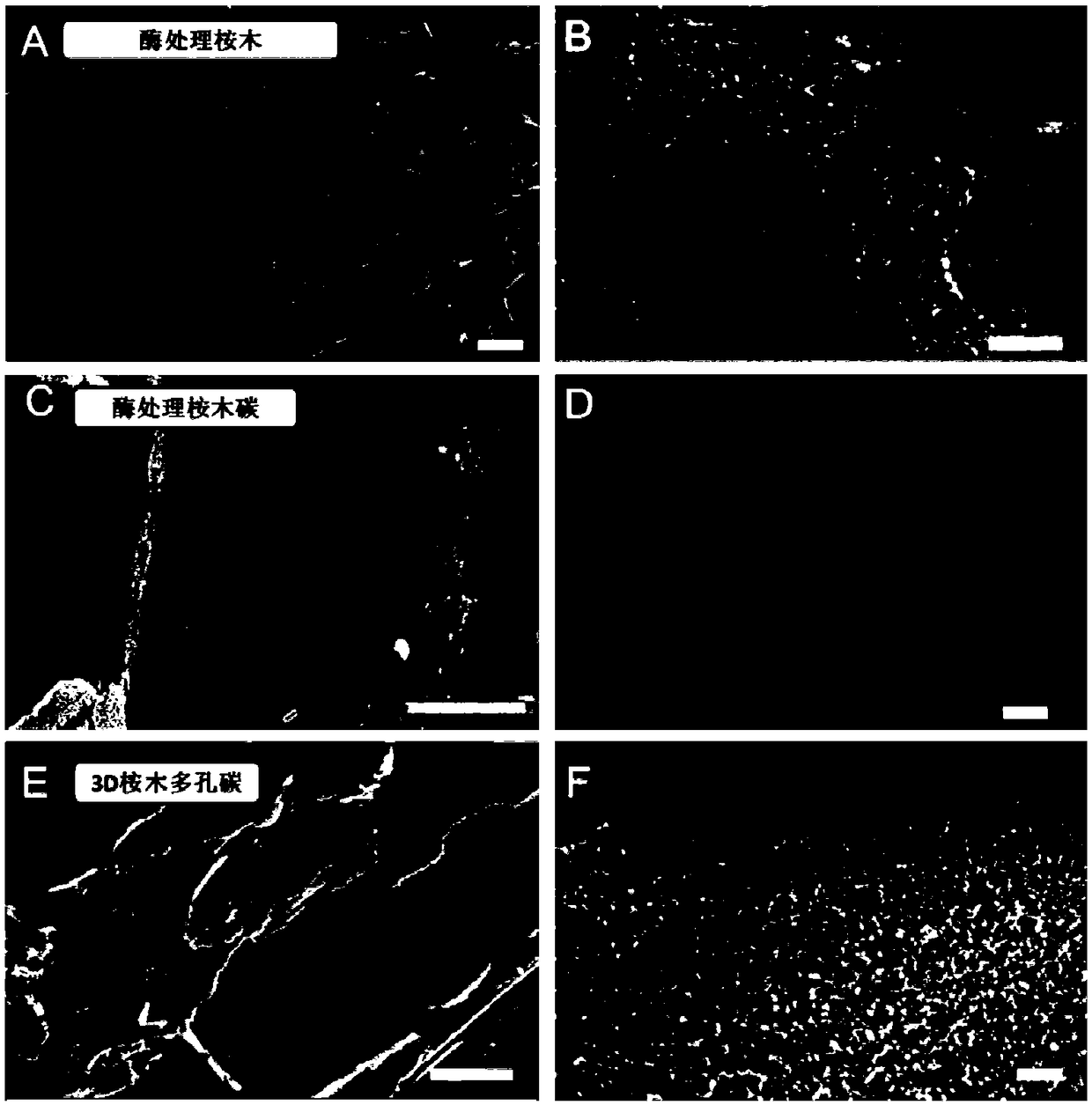

[0039] (1) Disperse 1g of eucalyptus in 50mL of 10U / mL cellulase solution (neutral conditions, cellulase purchased from Shanghai Yuanye Biotechnology Co., Ltd.), shake at a constant temperature of 40℃, 90rpm for 24h, filter , Washed with deionized water and dried at 60°C to obtain cellulase pretreated eucalyptus (ie, enzymatically treated eucalyptus);

[0040] (2) The eucalyptus pretreated by cellulase was calcined at a constant temperature at 700°C under nitrogen atmosphere for 1 hour (heating rate was 5°C / min) to obtain porous carbon material (ie enzyme-treated eucalyptus carbon);

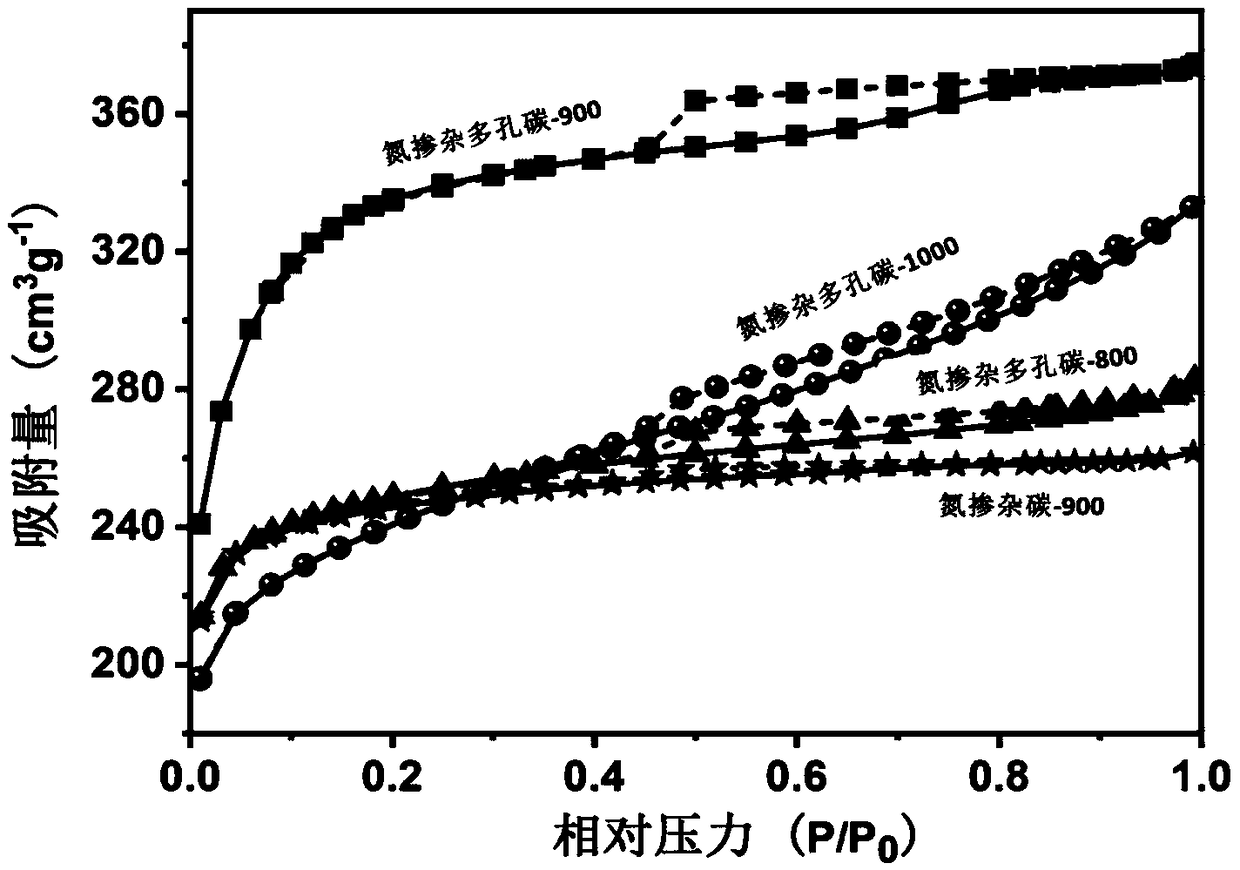

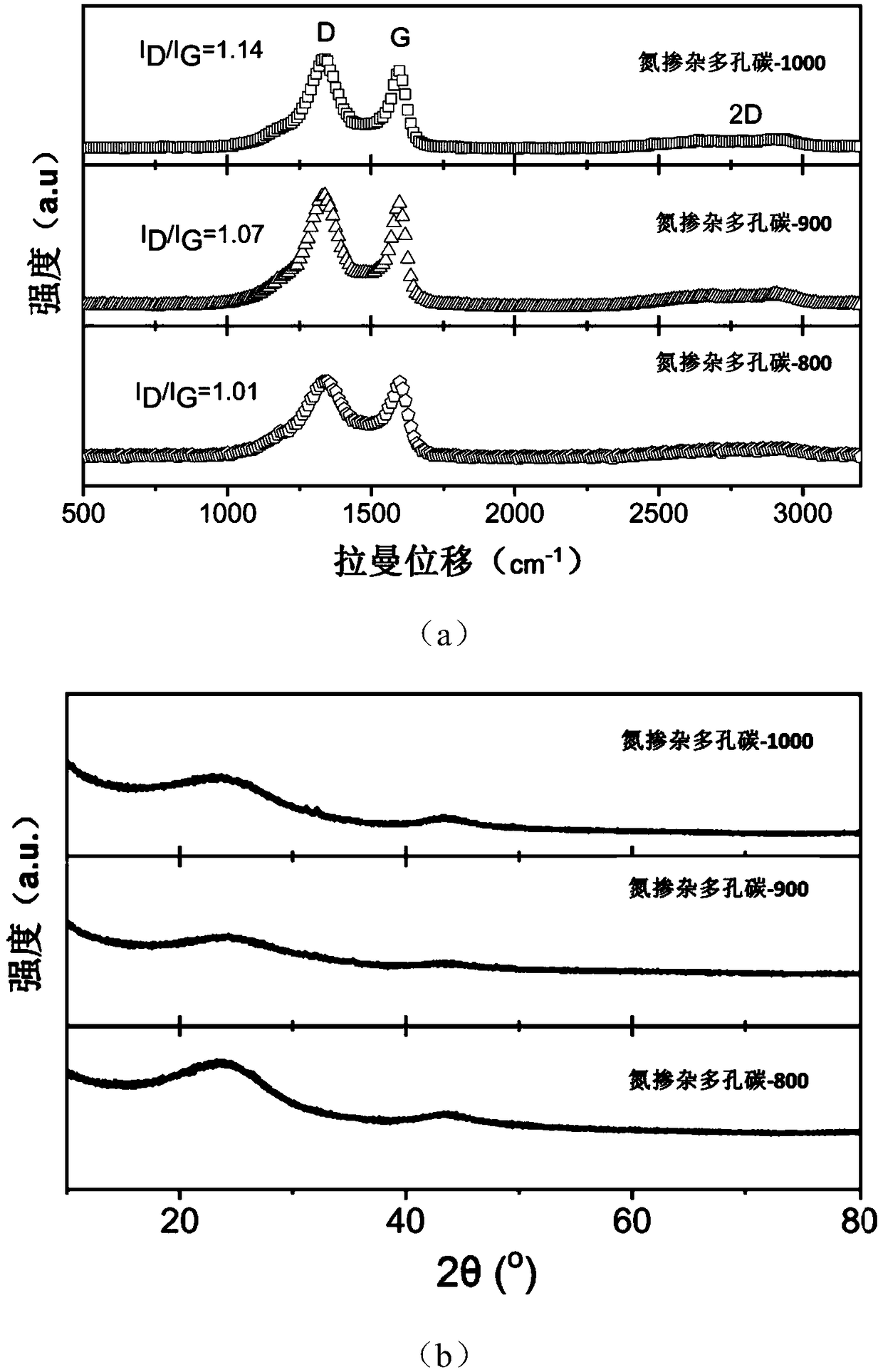

[0041] (3) Mix the porous carbon material and ammonium chloride in water at a mass ratio of 1:20 (the mass-volume ratio of ammonium chloride to water is 20g:60mL), evaporate to dryness at 60°C, and grind in a nitrogen atmosphere at 900°C After calcination for 2 hour...

Embodiment 2

[0043] A method for preparing a nitrogen-doped 3D porous carbon material by using cellulase pretreatment, including the following steps:

[0044] (1) Disperse 1g of eucalyptus in 50mL of 10U / mL cellulase solution (cellulase dissolved in water), shake at 40℃, 90rpm for 24h, filter, wash and dry to obtain cellulase pre Treated eucalyptus

[0045] (2) The eucalyptus pretreated by cellulase was calcined at a constant temperature at 700°C under nitrogen atmosphere for 1 hour (heating rate was 5°C / min) to obtain porous carbon material (ie enzyme-treated eucalyptus carbon);

[0046] (3) Mix the porous carbon material and ammonium chloride in water at a mass ratio of 1:20 (the mass-volume ratio of ammonium chloride to water is 20g:60mL), evaporate to dryness at 60℃, and grind under nitrogen at 800℃ After calcination for 2 hours, the eucalyptus-based nitrogen-doped porous carbon pretreated by Venzyme (ie, nitrogen-doped 3D porous carbon material, nitrogen-doped porous carbon-800) is obtained...

Embodiment 3

[0048] A method for preparing a nitrogen-doped 3D porous carbon material by using cellulase pretreatment, including the following steps:

[0049] (1) Disperse 1g of eucalyptus in 50mL of cellulase solution with a concentration of 10U / mL, shake at a constant temperature of 40℃, 90rpm for 24h, filter, wash with deionized water, and dry at 60℃ to obtain cellulase pretreated Eucalyptus (ie enzyme-treated eucalyptus);

[0050] (2) After eucalyptus pretreated by cellulase, the obtained eucalyptus is calcined at a constant temperature at 700°C under nitrogen atmosphere for 1 hour (heating rate is 5°C / min) to obtain porous carbon material (ie enzyme-treated eucalyptus carbon);

[0051] (3) Mix the porous carbon material and ammonium chloride in water at a mass ratio of 1:20 (the mass-volume ratio of ammonium chloride to water is 20g:60mL), evaporate to dryness at 60°C, and grind in a nitrogen atmosphere at 1000°C After calcination for 2 hours, the eucalyptus-based nitrogen-doped porous carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com