Indirect thermal desorption restoration system and method for treating mercury-containing solid waste and soil

A remediation system and soil treatment technology, applied in the field of indirect thermal desorption remediation system, can solve the problems that are difficult to remove and reuse ionic mercury, have not undergone industrial production and application, and are not suitable for the treatment of soil contaminated by high-concentration mercury compounds. , to achieve the effect of saving resources, realizing recycling, and suppressing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

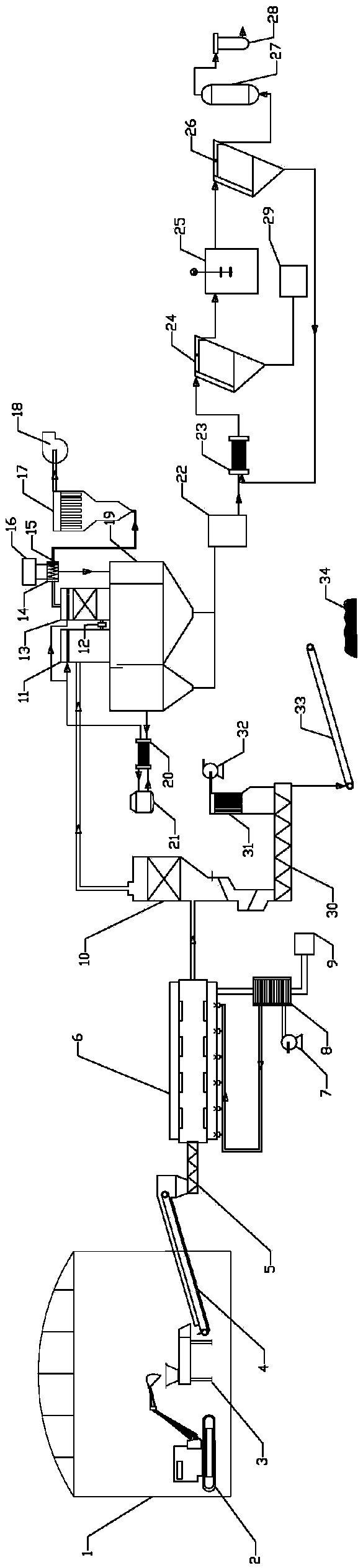

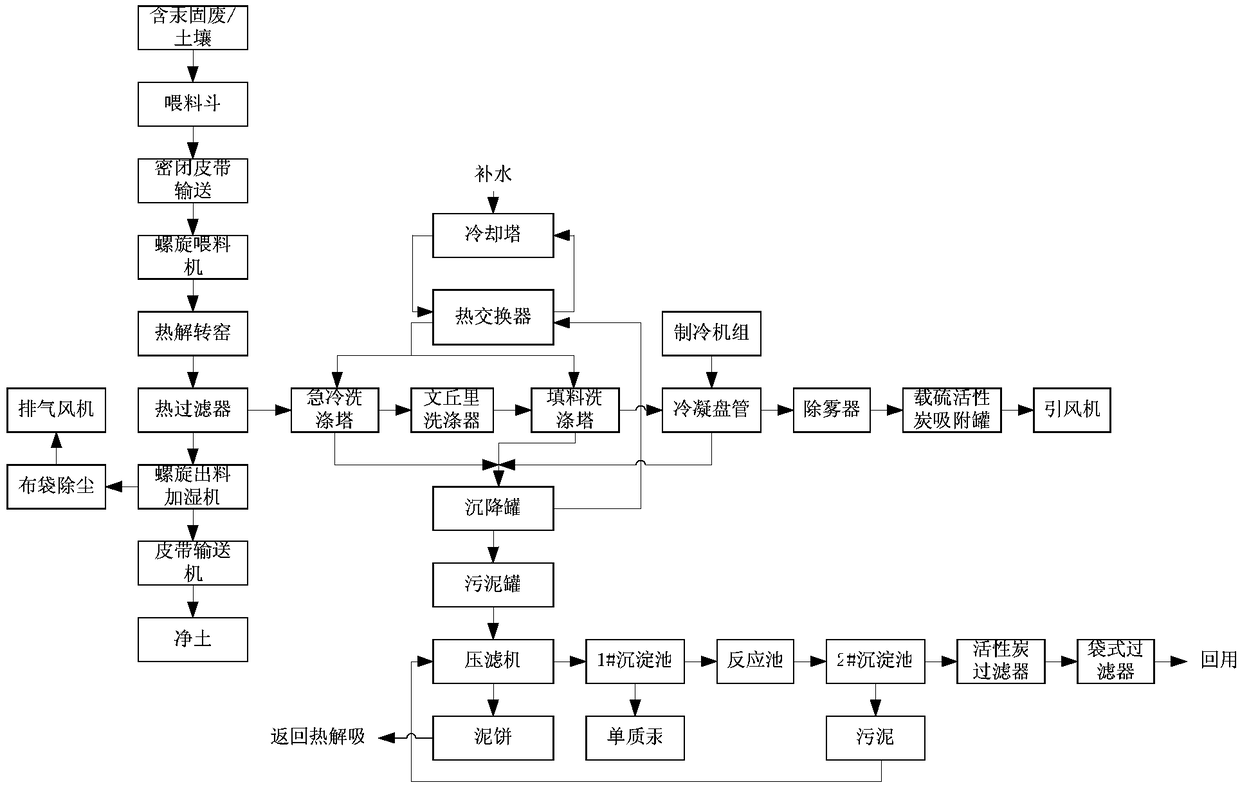

[0049] In a mercury-containing salt mud and soil remediation project, the figure 1 The shown indirect thermal desorption repair system is used to dispose of mercury-containing salt mud (the forms of mercury mainly include metallic mercury, mercury oxide, mercury sulfide, mercury chloride, etc.), and the heating temperature is set at 600-700 °C (round cavity outer wall temperature), the residence time of the material is controlled to be 40min by adjusting the rotating speed of the rotary kiln. After being processed by this system, samples were taken from the discharged material and the mercury concentration was measured. The results are shown in the table below.

[0050] Table 1 Analysis results of mercury content in salt mud before and after thermal desorption

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com