Water affinity type anti-pollution chlorine-resistant aramid composite membrane preparation method

A technology of aromatic polyamide and composite membrane, which is applied in the preparation of aromatic polyamide composite membrane and the preparation of water-wetting anti-fouling and chlorine-resistant aromatic polyamide composite membrane, which can solve the problems of marine biofouling and other problems, and achieve the goal of avoiding chemical pollution. Destruction, high hydrophilicity, easy industrialization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of water-wetting antifouling and chlorine-resistant aromatic polyamide composite membrane (1)

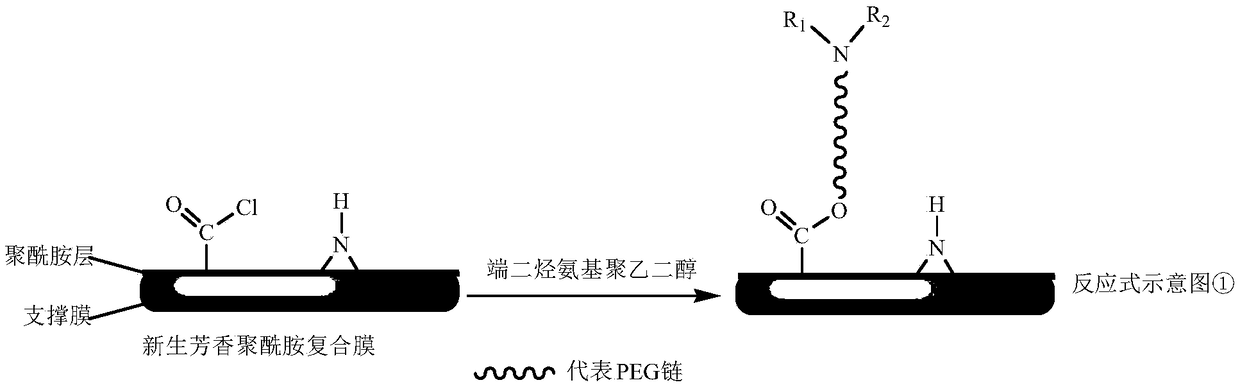

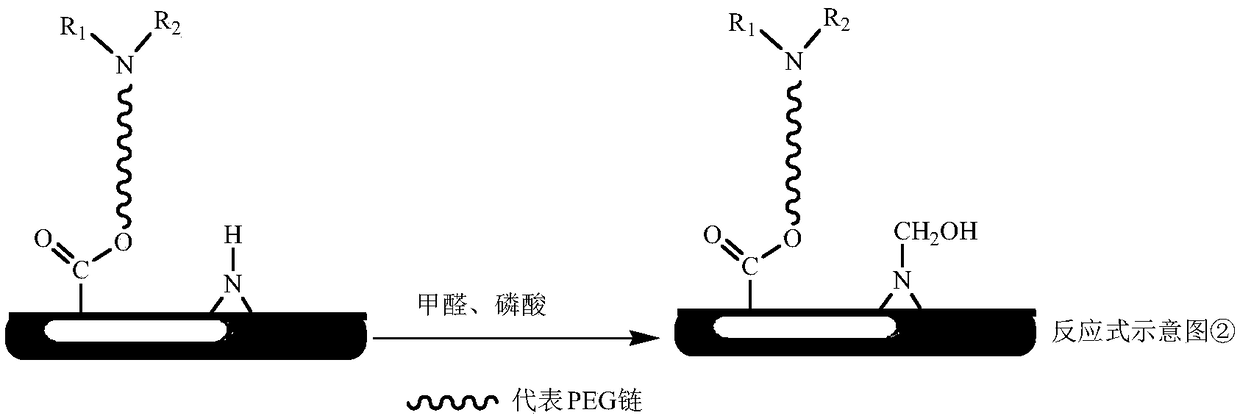

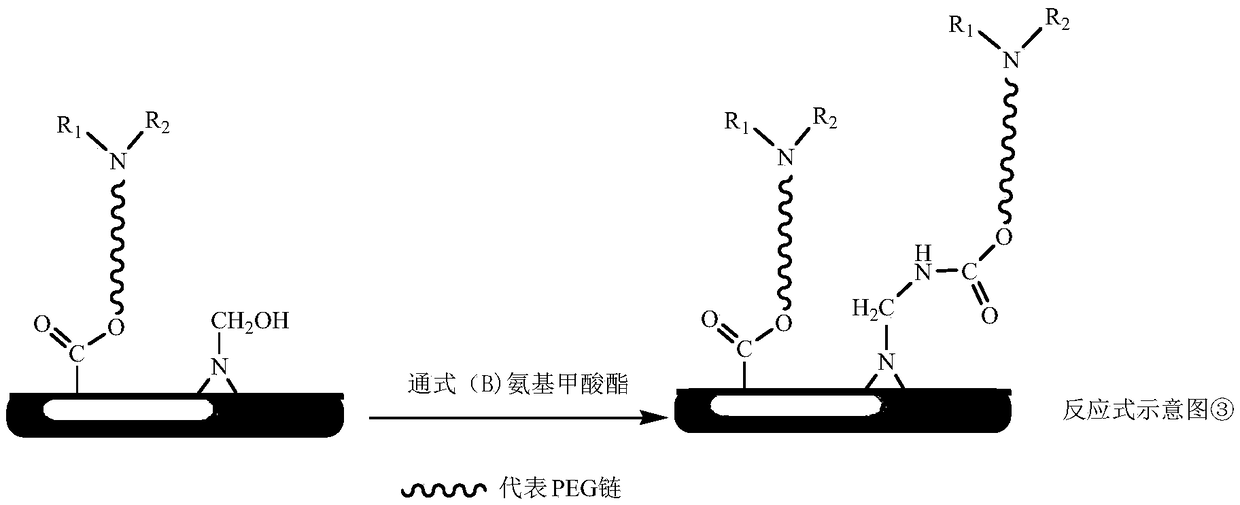

[0037] Step 1 Preparation of aromatic polyamide composite membrane grafted with dimethylamino-PEG chains on the surface

[0038] According to the methods and operating steps disclosed in Journal of Membrane Science 428 (2013) 403-409 or Journal of Membrane Science 457 (2014) 88-97, CN103349922B or CN105251372B, on the surface of the 10*10cm square microporous polysulfone support membrane, The nascent aromatic polyamide composite film containing acid chloride groups on the surface was prepared by interfacial polymerization of m-phenylenediamine and trimesoyl chloride, and the nascent aromatic polyamide composite film containing acid chloride groups on the surface was impregnated in dimethylaminopolyethylene Alcohol-600 (also known as dimethylamino PEG-600) in a mixed solution of 1,4-dioxane (20mL) and triethylamine (10mL) with a concentration of 5.5% by m...

Embodiment 2

[0045] Example 2 Preparation of water-wetting anti-fouling and chlorine-resistant aromatic polyamide composite membrane (2)

[0046] According to the method and operation steps of Example 1, the dimethylamino PEG-600 in Step 3 of Example 1 was replaced with dimethylamino PEG-2000 to obtain a water-wet anti-fouling and chlorine-resistant aromatic polyamide composite membrane ( 2).

Embodiment 3

[0047] Example 3 Preparation of water-wetting anti-fouling and chlorine-resistant aromatic polyamide composite membrane (3)

[0048] According to the method and operation steps of Example 1, the N,N-dimethylethanolamine in Step 3 of Example 1 was replaced with diethylaminopolyethylene glycol-2000 to obtain a water-wetting anti-fouling and chlorine-resistant aromatic Polyamide composite membrane (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com