Novel hydroxide lanthanum-modified hydroxyapatite material and preparation method and application thereof

A technology of hydroxyapatite and lanthanum hydroxide, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problem of low phosphate removal rate and adsorption efficiency, which have not been reported, Small adsorption capacity and other problems, to achieve the effect of no secondary pollution risk, wide application range and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Add lanthanum chloride to the container, add deionized water to achieve a solid-to-liquid ratio of 1:80, and adjust the pH to 4.5 with 0.075mol / L hydrochloric acid solution;

[0052] 2) Add hydroxyapatite solution to make the lanthanum-calcium mass ratio of the mixed solution 10:1, adjust the pH of the mixed solution to 9 with 0.2mol / L NaOH solution, and stir for 2 hours;

[0053] 3) Put the stirred mixed solution into an ultrasonic instrument for ultrasonication, and adjust the ultrasonic intensity to 100W / m 2 Ultrasound 4h;

[0054] 4) Continue stirring the ultrasonically mixed solution on the stirrer at a stirring rate of 200rpm for 3.5h;

[0055] 5) Stop stirring, and seal and age for 6 hours;

[0056] 6) Pour off the supernatant of the aged solution and leave the precipitate, wash the precipitate repeatedly with deionized water until neutral, and filter it quickly;

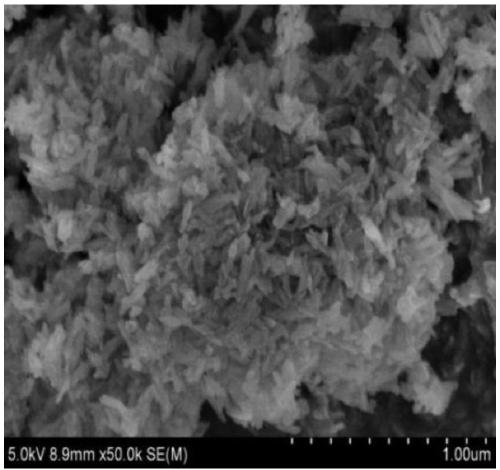

[0057] 7) Put the filtered residue into a blast oven, dry it at 70°C for 24h, and then bake i...

Embodiment 2

[0065] 1) Add lanthanum chloride to the container, add deionized water to achieve a solid-to-liquid ratio of 1:100, and adjust the pH to 5 with 0.1mol / L hydrochloric acid solution;

[0066] 2) Add hydroxyapatite solution to make the lanthanum-calcium mass ratio of the mixed solution 1:1, adjust the pH of the mixed solution to 10 with 0.1mol / L NaOH solution, and stir for 3 hours;

[0067] 3) Put the stirred mixed solution into an ultrasonic instrument for ultrasonication, and adjust the ultrasonic intensity to 200W / m 2 Ultrasound 1h;

[0068] 4) Continue stirring the ultrasonically mixed solution for 5 h at a stirring rate of 150 rpm on the stirrer;

[0069] 5) Stop stirring, seal and age for 8 hours;

[0070] 6) Pour off the supernatant of the aged solution and leave the precipitate, wash the precipitate repeatedly with deionized water until neutral, and filter with suction;

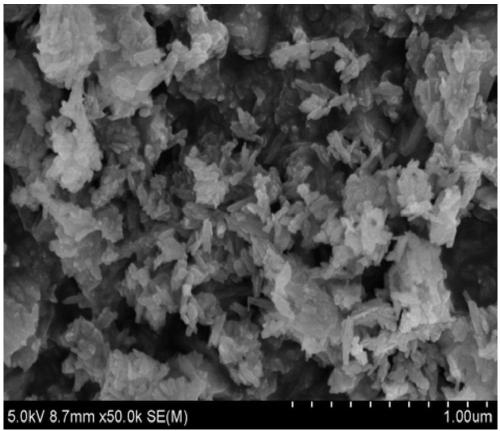

[0071] 7) Put the filter residue obtained by suction filtration into a vacuum oven, dry at 75°C fo...

Embodiment 3

[0078] 1) Add lanthanum chloride to the container, add deionized water to achieve a solid-to-liquid ratio of 1:120, and adjust the pH to 6 with 0.2mol / L hydrochloric acid solution;

[0079] 2) Add hydroxyapatite solution so that the mass ratio of lanthanum to calcium in the mixed solution is 1:5, adjust the pH of the mixed solution to 12 with 0.075mol / L KOH solution, and stir for 4 hours;

[0080] 3) Put the stirred mixed solution into an ultrasonic instrument for ultrasonication, and adjust the ultrasonic intensity to 250W / m 2 Ultrasonic 0.5h;

[0081] 4) Continue stirring the ultrasonically mixed solution for 18 hours at a stirring rate of 80 rpm on the stirrer;

[0082] 5) Stop stirring, and seal and age for 5 hours;

[0083] 6) Pour off the supernatant of the aged solution and leave the precipitate, wash the precipitate repeatedly with deionized water until neutral, and filter with suction;

[0084] 7) Put the filter residue obtained by suction filtration into a vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com