Heterojunction micron box composite photocatalyst as well as preparation method and application thereof

A heterojunction, composite light technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as soil and water pollution, achieve high-efficiency treatment technology, easy operation, The effect of green environmental protection treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a heterojunction micro box composite photocatalyst comprises the following steps:

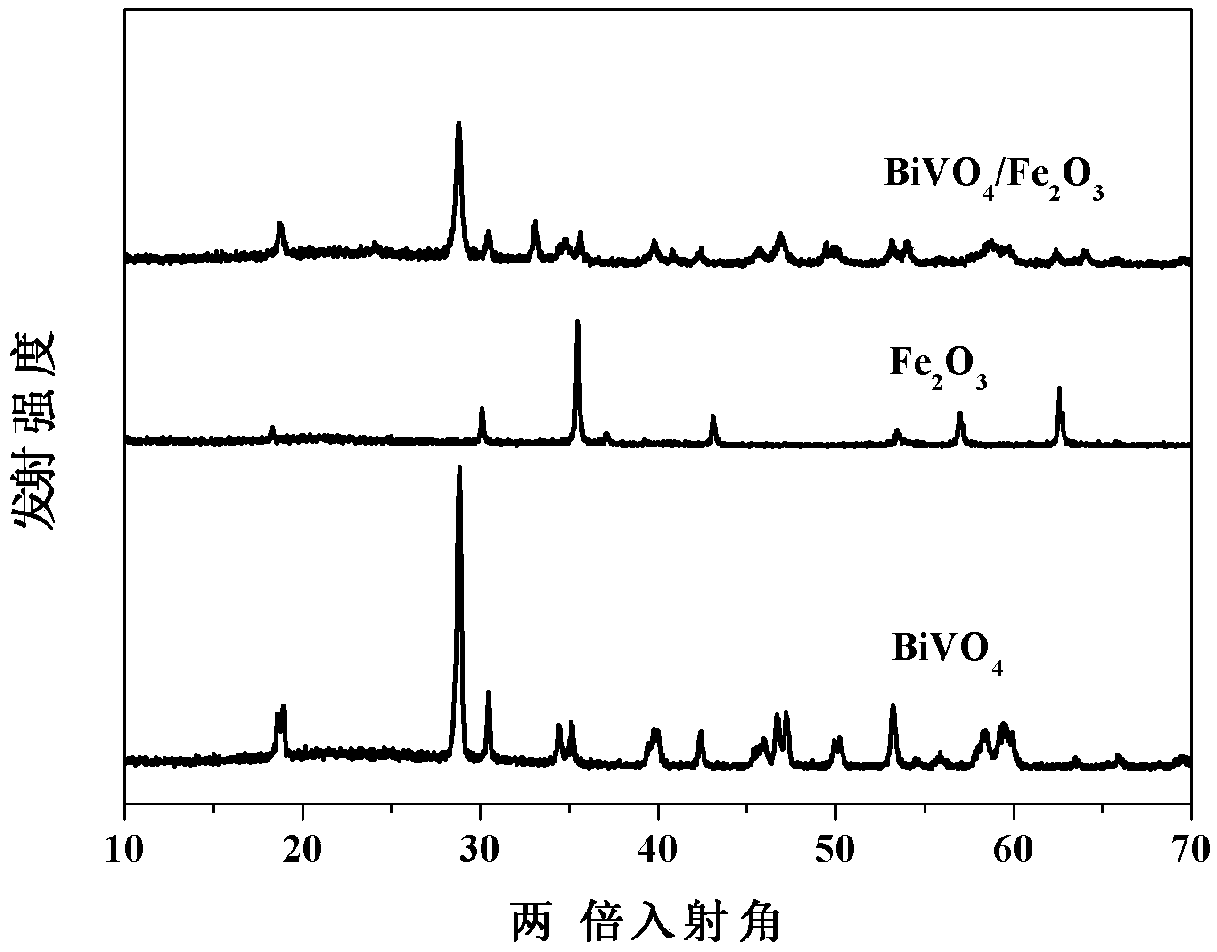

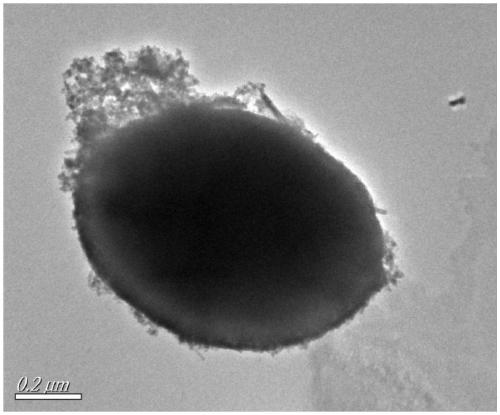

[0026] Step S1, preparing Fe 2 o 3 Micron box:

[0027] Add the NaOH solution to the FeCl with continuous stirring at 75 °C over 5 min 3 Medium solution, NaOH and FeCl 3 The molar ratio is 2.7:1, the obtained Fe(OH) 3 The gel was continuously stirred at the same temperature of 75°C for 5 minutes, and then aged in a preheated oven at 100°C for 4 days. The red product was collected and washed three times with deionized water and ethanol. The amount of deionized water was such that the solid could be completely dissolved. Yes, then dried overnight at 70°C to give Fe 2 o 3 micron box.

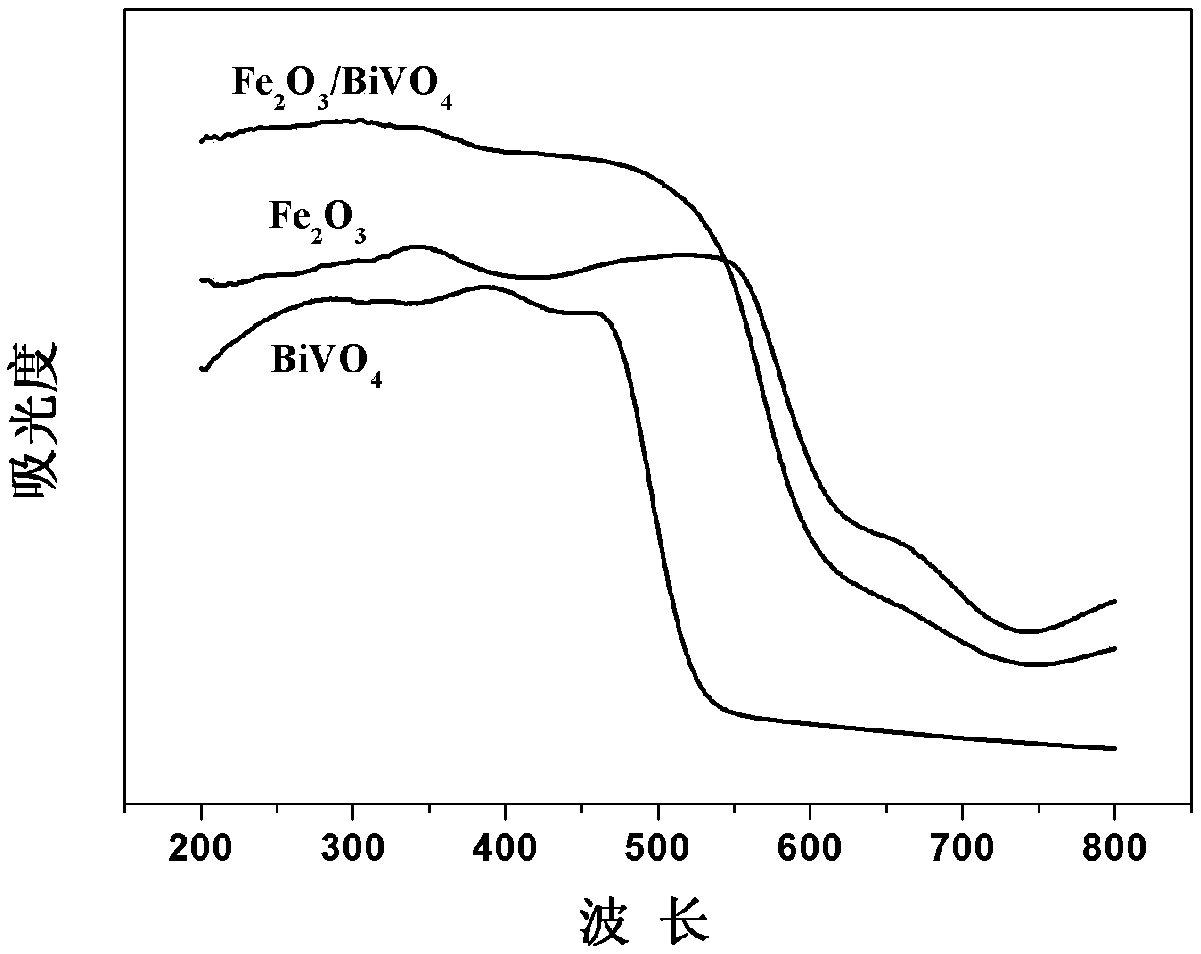

[0028] Step S 2. Preparation of Fe 2 o 3 / BiVO 4 Heterojunction Microbox Composite Photocatalyst:

[0029] Take Bi(NO 3 ) 3 .5H 2 O is dissolved in ethylene glycol in an amount such that Bi(NO 3 ) 3 .5H 2 Until the O is completely dissolved, magnetically stir and ultra...

Embodiment 1

[0035] Step S1, Fe 2 o 3 Preparation of the micron box:

[0036] Add the NaOH solution to the FeCl with continuous stirring at 75 °C over 5 min 3 solution, the obtained Fe(OH) 3 The gel was continuously stirred at the same temperature of 75 °C for 5 min, and then aged in a preheated oven at 100 °C for 4 days. The red product was collected and washed three times with deionized water and ethanol, then dried at 70 °C overnight. That is, get Fe 2 o 3 micron box.

[0037] Step S2, Fe 2 o 3 / BiVO 4 Preparation of Heterojunction Microbox Composite Photocatalyst:

[0038] Take 0.6mmolBi(NO 3 ) 3 .5H 2 O is dissolved in ethylene glycol, magnetically stirred, and ultrasonically dissolved. After the particles are uniform, add the 3mmolFe prepared in the step S1 2 o 3 Powder to obtain mixed test solution 1, magnetically stirred for 1 hour and then left to stand for 1 hour; take ammonium metavanadate and dissolve it in ethylene glycol, slowly add it to mixed test solution 1 ...

Embodiment 2

[0041] Step S1, Fe 2 o 3 Preparation of the micron box:

[0042] Add the NaOH solution to the FeCl with continuous stirring at 75 °C over 5 min 3 In solution, the resulting Fe(OH) 3 The gel was continuously stirred at the same temperature of 75 °C for 5 min, and then aged in a preheated oven at 100 °C for 4 days. The red product was collected and washed three times with deionized water and ethanol, then dried at 70 °C overnight. That is, get Fe 2 o 3 micron box.

[0043] Step S2, Fe 2 o 3 / BiVO 4 Preparation of Heterojunction Microbox Composite Photocatalyst:

[0044] Take 0.75mmolBi(NO 3 ) 3 .5H 2 O is dissolved in ethylene glycol, magnetically stirred, and ultrasonically dissolved. After the particles are uniform, add the 3mmolFe prepared in the step S1 2 o 3 Powder, to obtain mixed test 1, the liquid was magnetically stirred for 1 hour and then left to stand for 1 hour; ammonium metavanadate was dissolved in ethylene glycol, slowly added to mixed test solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com