Heat-insulation material and method

A technology of thermal insulation materials and fungicides, applied in the field of thermal insulation materials, can solve the problems of poor thermal insulation performance, easy falling off, and hidden safety hazards of buildings, and achieve the effects of excellent thermal insulation performance, saving resource materials, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

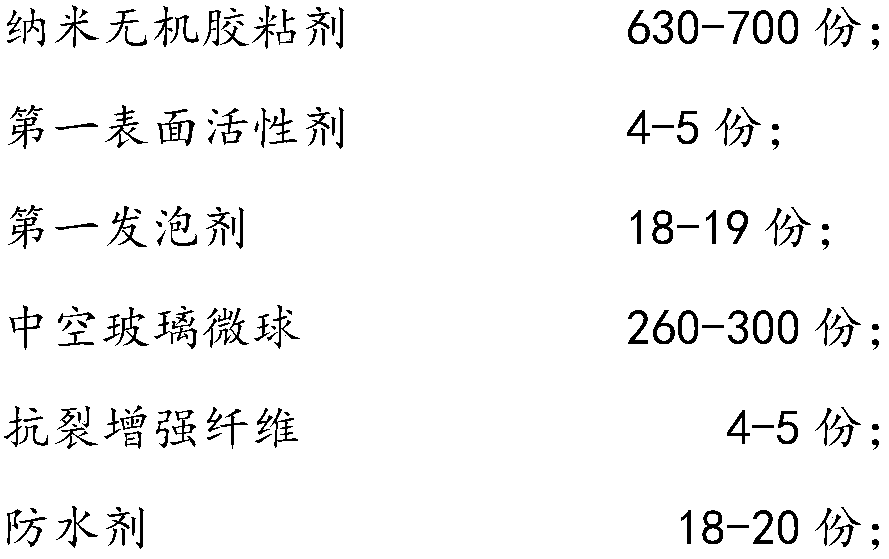

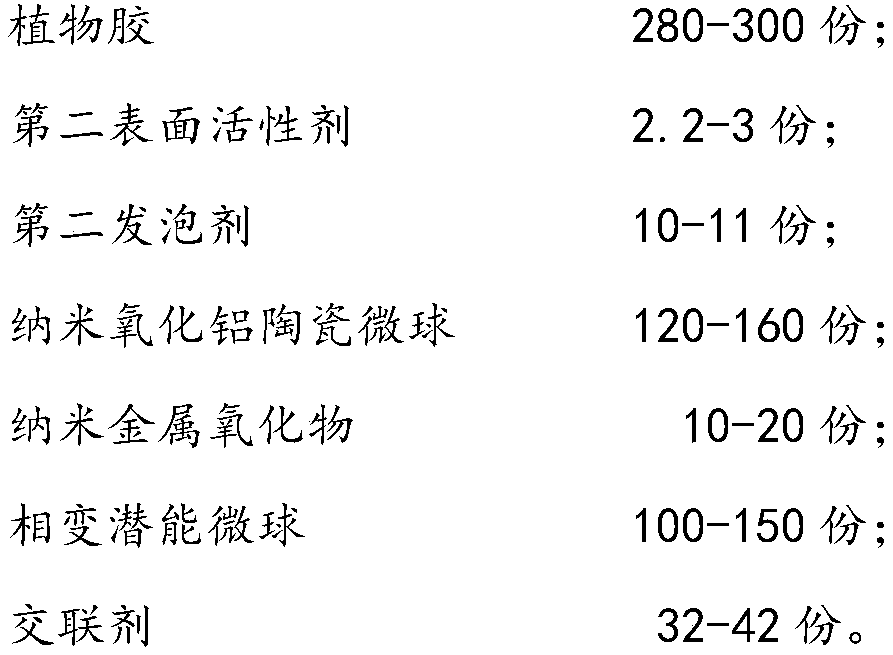

Method used

Image

Examples

preparation example Construction

[0102] Described preparation method comprises the steps:

[0103] Add the first surfactant and the first blowing agent to the nano-inorganic adhesive and stir and mix for 3-5 minutes; add the hollow glass microspheres and stir and mix for 10-15 minutes; add the anti-cracking enhancer in turn Fiber, waterproofing agent and first fungicide, continue to stir and mix for 10-15 minutes.

[0104] As a preference, said slurry A also includes 1.3-1.5 parts of foam stabilizer;

[0105] Described preparation method comprises the steps:

[0106] Add the nano-inorganic adhesive into the horizontal stepless variable speed strong mixer according to the formula, and add the first surfactant and the first foaming agent in sequence under stirring at a speed of 60-80 rpm for 3-5 minutes; keep Slowly add hollow glass microspheres at the above rate, and after adding, adjust the speed to 100-120 rpm and keep for 10-15 minutes; add anti-cracking reinforcing agent fiber, waterproofing agent and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com