Adhesive used for low surface energy surface bonding, and preparation method thereof

A surface bonding, low surface energy technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc. Adhesion, highlighting the effect of high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

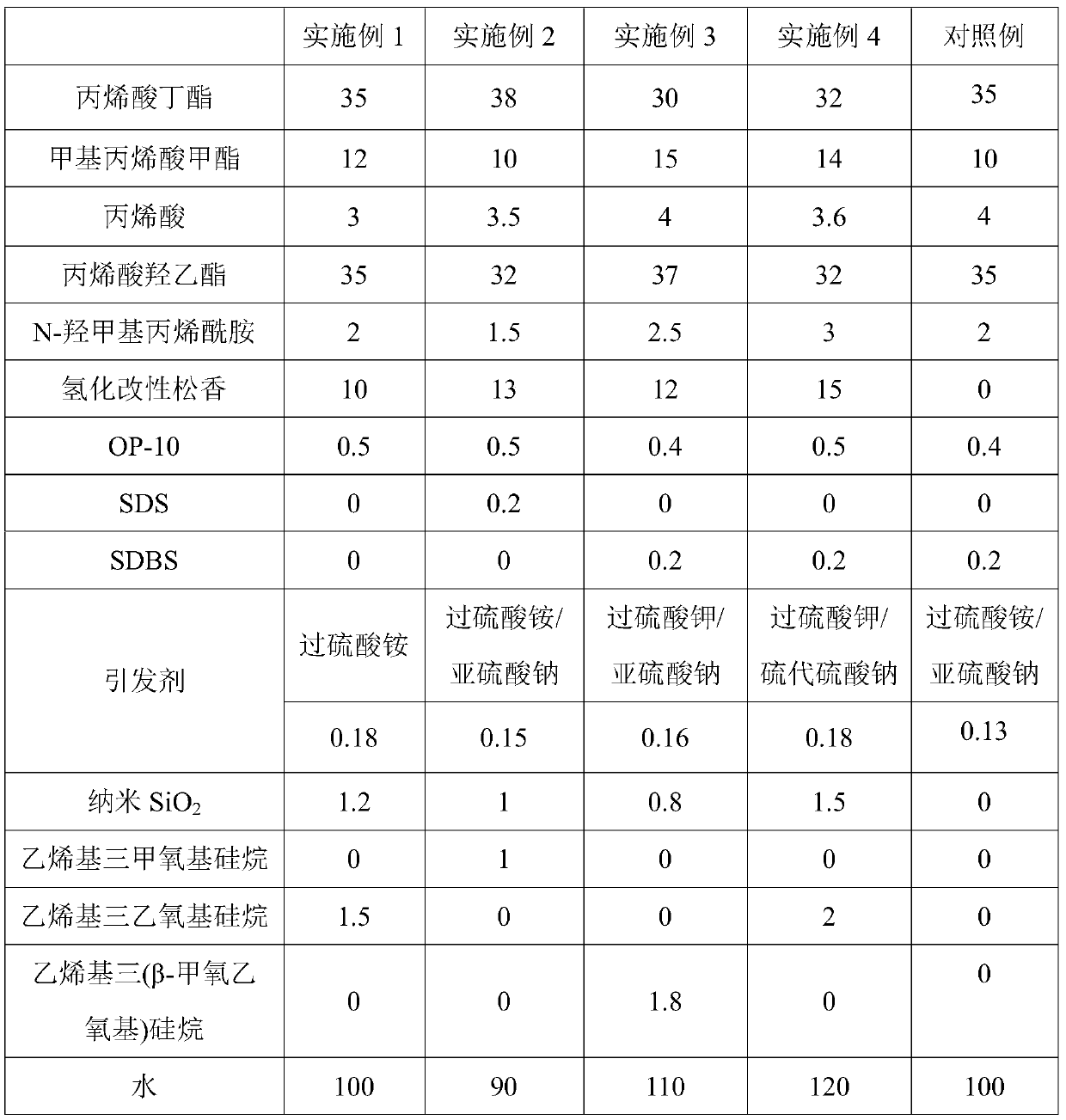

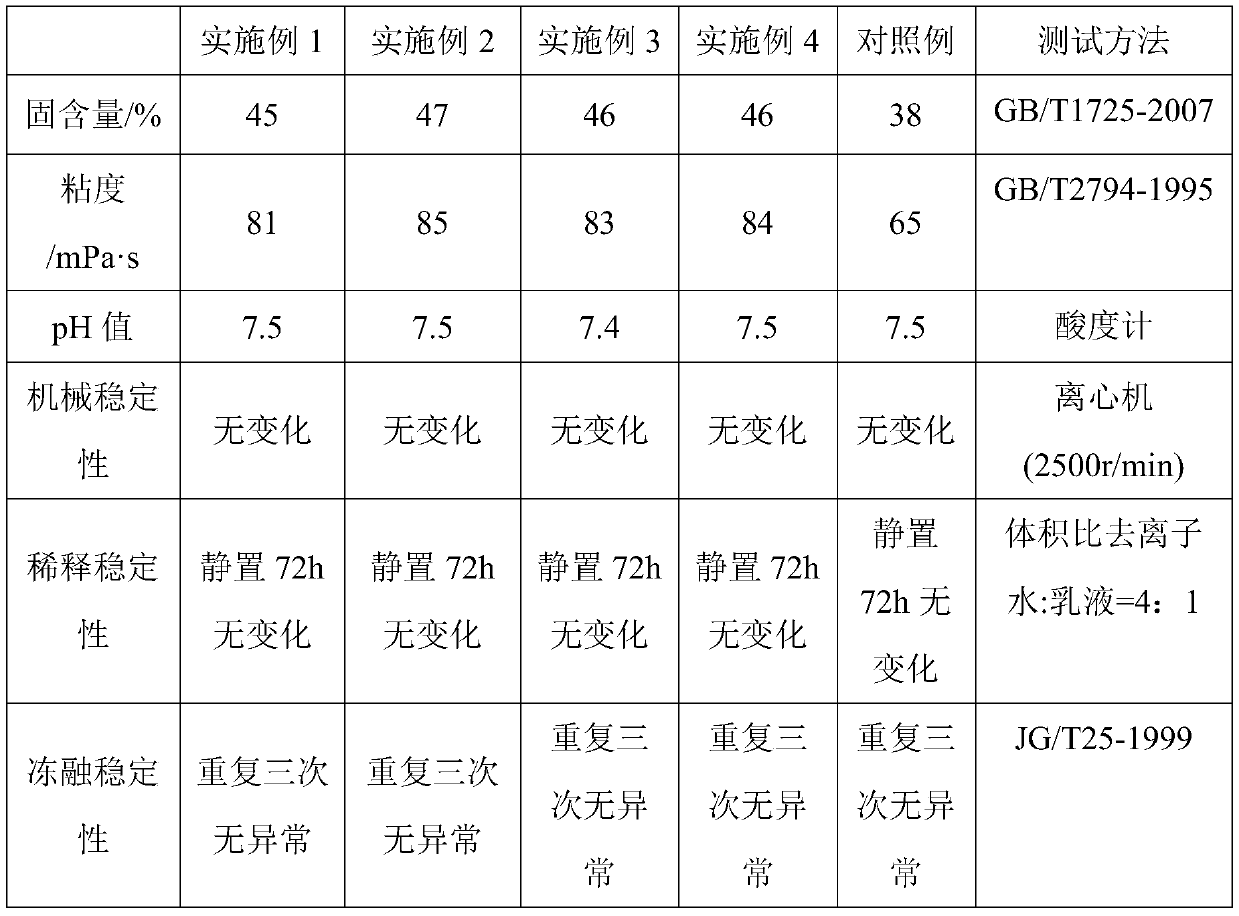

[0035] An adhesive for low surface energy surface bonding, made of the following components in parts by weight:

[0036] 30-40 parts of butyl acrylate; 10-15 parts of methyl methacrylate; 3-4 parts of acrylic acid; 30-40 parts of hydroxyethyl acrylate; 1-3 parts of N-methylolacrylamide; 10 parts of hydrogenated modified rosin ~15 parts; emulsifier 0.5~1 part; initiator 0.1~0.2 part; nano-SiO 2 0.5-1.5 parts; 1-2 parts of unsaturated silane coupling agent; 80-120 parts of water. nano-SiO 2 Particles with 50m 2 / g~200m 2 The specific surface area per g preferably has a narrow particle size distribution, and the dispersibility is preferably 1.5 to 2.0.

[0037] A preparation method of the above-mentioned adhesive for low surface energy surface bonding, comprising the steps of:

[0038] S1, Nano SiO 2 Surface treatment of particles: surface treatment of nanoparticles with unsaturated silane coupling agent;

[0039] S2. Synthesis of organic-inorganic nanocomposite pressure-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com