A water plugging method for horizontal wells with screen tubes

A technology for horizontal wells and screens, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc. It can solve the problem of no effective mechanical segmentation method, difficult to judge the water-producing well section, and difficult to plug water with water blocking agents. and other problems, to achieve the effect of improving crude oil fluidity, improving production effect and high plugging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

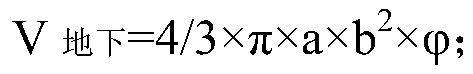

[0110] In this example, the performance of the powder temporary plugging agent is evaluated, and artificial cores are used to conduct water phase and oil phase plugging rate experiments on the powder temporary plugging agent.

[0111]The powder temporary plugging agent of different concentrations (the powder temporary plugging agent with different percentages in the mixed solution of the powder temporary plugging agent and the water-based plugging agent, the powder temporary plugging agent adopted is 3:1 by mass ratio: 1 resin granules, bamboo charcoal granules and copal granules are mixed, and the particle size is 1mm. The raw materials of the water-based plugging agent used are polyacrylamide 2.0%, sodium humate 4.0%, hexamethylenetetramine 0.15%, 1.0% sodium phenate, 0.25% glacial acetic acid, 0.1% cyclohexyl hexaphosphate, and the rest of the water. The degree of hydrolysis of polyacrylamide is 20%, and the molecular weight is 20 million.) Mix with artificial quartz sand, p...

Embodiment 2

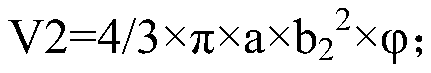

[0119] In this example, the performance of the water-based plugging agent is evaluated, and the fluidity of the water-based plugging agent with different concentrations at different times is tested. The results are shown in Table 2.

[0120] experiment procedure:

[0121] Prepare 4 groups of water-based plugging bases with different concentrations, and test their viscosity at 60°C for different time periods, and the unit is mPa·s.

[0122] Formula 1: polyacrylamide (1.0%), sodium humate (3.0%), hexamethylenetetramine (0.5%), sodium phenate (0.5%), glacial acetic acid (0.05%), cyclohexanehexa Phosphate (0.05%), balance water. The degree of hydrolysis of polyacrylamide is 20%, and the molecular weight is 20 million.

[0123] Formula 2: polyacrylamide (1.5%), sodium humate (3.5%), hexamethylenetetramine (1.0%), sodium phenate (0.8%), glacial acetic acid (0.2%), hexacyclohexyl Phosphate (0.1%), balance water. The degree of hydrolysis of polyacrylamide is 20%, and the molecula...

Embodiment 3

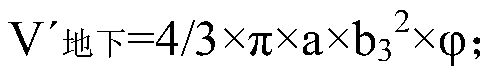

[0130] This example provides a performance evaluation test for the composite temperature-resistant plugging agent.

[0131] experiment procedure:

[0132] Prepare two sets of formulations of the lowest / highest concentration composite temperature-resistant plugging agent, observe the curing time of the two sets of formulations, and test the compressive strength after curing;

[0133] Put two sets of composite temperature-resistant plugging agents into a muffle furnace at 350°C for 30 days, take them out to observe their shape, and test their compressive strength. The results are shown in Table 3.

[0134] Formula 1: 8% calcium sulfate dihydrate, 4% hydrous silicic acid powder, 4% sodium bentonite, 0.5% mannitol, 0.5% low molecular weight polyacrylamide, 0.05% m-phenylenediamine, 0.05% sodium hydroxide, and The amount is water, the degree of hydrolysis of low molecular weight polyacrylamide is 15%, and the molecular weight is 2.5 million.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com