An all-solid-state flexible supercapacitor and a preparation method thereof

A supercapacitor and all-solid-state technology, applied in the field of energy storage, can solve problems such as toxicity, safety hazards of supercapacitors, and non-compliance with the development trend of green environmental protection materials and devices, and achieve the effects of low cost, abundant sources, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

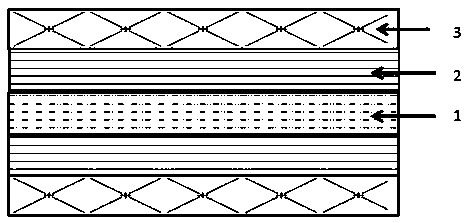

[0027] The preparation of the used sodium copper chlorophyllin electrode, its specific process is as follows:

[0028] (1) Weigh sodium copper chlorophyllin and binder PVDF according to the mass ratio of 8.5:1.5, and pour them into a small beaker. An appropriate amount of organic solvent NMP was added dropwise, and magnetically stirred for about 4 hours.

[0029] (2) Cut the nickel foam according to the specifications of 2cm×2cm, and draw two strips from the corners as electrode contacts.

[0030] (3) Take out the evenly stirred slurry, apply the slurry evenly on the nickel foam with a film applicator, place the electrode in a vacuum drying oven at 100 ℃ to dry, take it out and use it as an electrode material.

[0031] The fabrication process of the supercapacitor based on sodium copper chlorophyllin electrode is as follows:

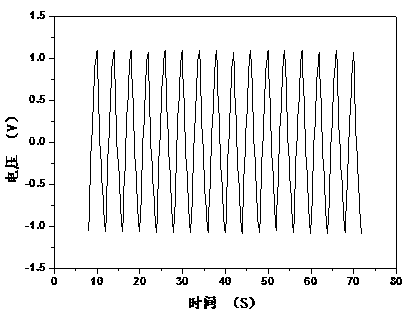

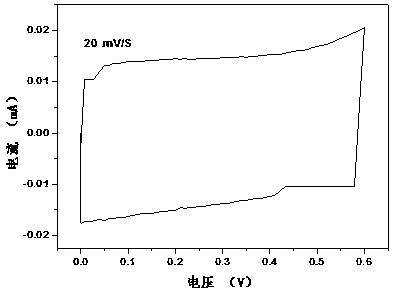

[0032] 1) Add 4g of PVA to 40mL of ultrapure water, raise the temperature to 95°C under mechanical stirring, and continue stirring until the solution ...

Embodiment 2

[0040] The preparation of the used sodium copper chlorophyllin electrode, its specific process is as follows:

[0041] (1) Weigh sodium copper chlorophyllin and binder PVDF according to the mass ratio of 8.5:1.5, and pour them into a small beaker. An appropriate amount of organic solvent NMP was added dropwise, and magnetically stirred for about 4 hours.

[0042] (2) Cut the nickel foam according to the specifications of 2cm×2cm, and draw two strips from the corners as electrode contacts.

[0043] (3) Take out the evenly stirred slurry, apply the slurry evenly on the nickel foam with a film applicator, place the electrode in a vacuum drying oven at 100 ℃ to dry, take it out and use it as an electrode material.

[0044] The fabrication process of the supercapacitor based on sodium copper chlorophyllin electrode is as follows:

[0045] 1) Mix 8 g of PVA and 5.7 mL of H 2 SO 4 Add it to 110mL of ultrapure water, put it into a water bath, raise the temperature to 90°C under me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com