Water-absorbing resin particles, process for producing same, and absorbent object and absorbent article both comprising or including same

A technology of resin particles and manufacturing methods, applied in chemical instruments and methods, other chemical processes, etc., which can solve the problems of long-term use of water-absorbent articles, obstruction of hygienic materials, and reduction of water-absorbing performance of water-absorbent resins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

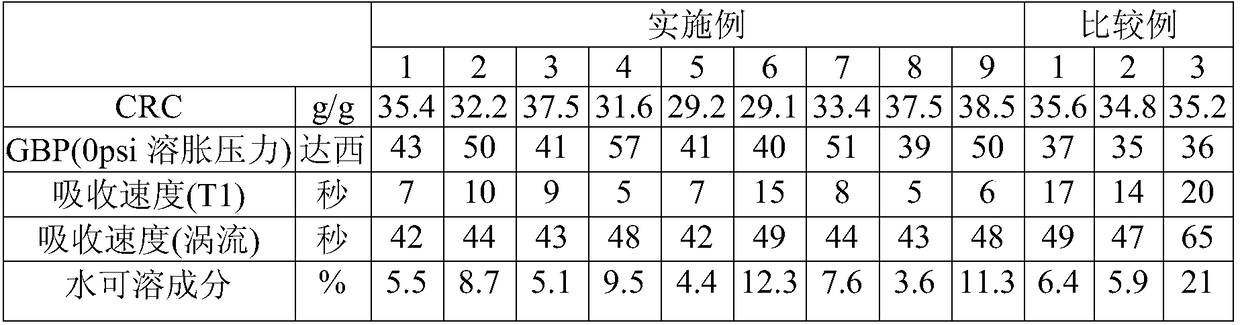

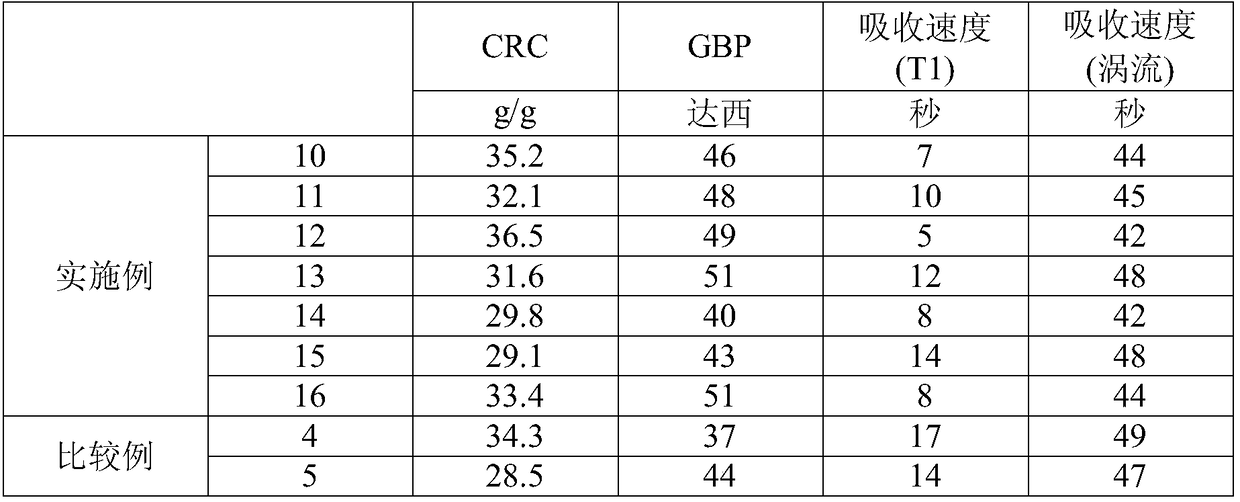

Examples

Embodiment 1

[0141] 135 parts of acrylic acid (manufactured by Mitsubishi Chemical Corporation, purity 100%, the same below), 0.68 parts of pentaerythritol triallyl ether (manufactured by DAISO Corporation, the same below), sodium bisulfite (manufactured by Wako Pure Chemical Industries, Ltd., purity 66%, hereinafter the same) 0.02 parts and 363 parts of deionized water were stirred and mixed while maintaining at 3°C. Nitrogen gas was blown into the mixture to reduce the amount of dissolved oxygen to 1 ppm or less, and then 0.5 parts of 1% aqueous hydrogen peroxide solution, 1 part of 2% aqueous ascorbic acid solution and 2% of 2,2'-azobisamidinopropane di-salt were added. 0.3 parts of aqueous salt solution and mixed to initiate polymerization. After the temperature of the mixture reached 80°C, it was polymerized at 80±2°C for about 5 hours, whereby a hydrogel (1) was obtained.

[0142] Next, the obtained hydrogel (1) was completely chopped with a mincer (12VR-400K manufactured by ROYAL C...

Embodiment 2

[0145] Change "0.68 parts of pentaerythritol triallyl ether" to "0.2 parts of pentaerythritol", change "0.02 parts of sodium bisulfite" to "1.9 parts of phosphoric acid (manufactured by Kanto Chemical Co., Ltd., purity 85%, the same below)", Changed "moisture content 6%" to "moisture content 8%", changed "2% aqueous solution of ethylene glycol diglycidyl ether 4 parts" to "3% aqueous solution of ethylene glycol diglycidyl ether 6.6 parts ", and obtained the water-absorbent resin particles (2) of the present invention in the same manner as in Example 1.

Embodiment 3

[0147] Change "0.68 parts of pentaerythritol triallyl ether" to "0.82 parts of pentaerythritol triallyl ether", change "0.02 parts of sodium bisulfite" to "0.008 parts of sodium bisulfite", and change "moisture content to 6 %" was changed to "moisture content is 4%", and "4 parts of a 2% aqueous solution of ethylene glycol diglycidyl ether" was changed to "5 parts of a 1% aqueous solution of ethylene glycol diglycidyl ether". The water-absorbent resin particles (3) of the present invention were obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com