Composite flavor enhancer and preparation method and application thereof

A technology of flavoring agent and solvent, applied in the field of compound flavoring agent and its preparation, can solve the problems of typical synthetic flavor, poor flavor, easy volatilization loss, etc., and achieves increased types and content, obvious flavoring effect, and increased peak area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

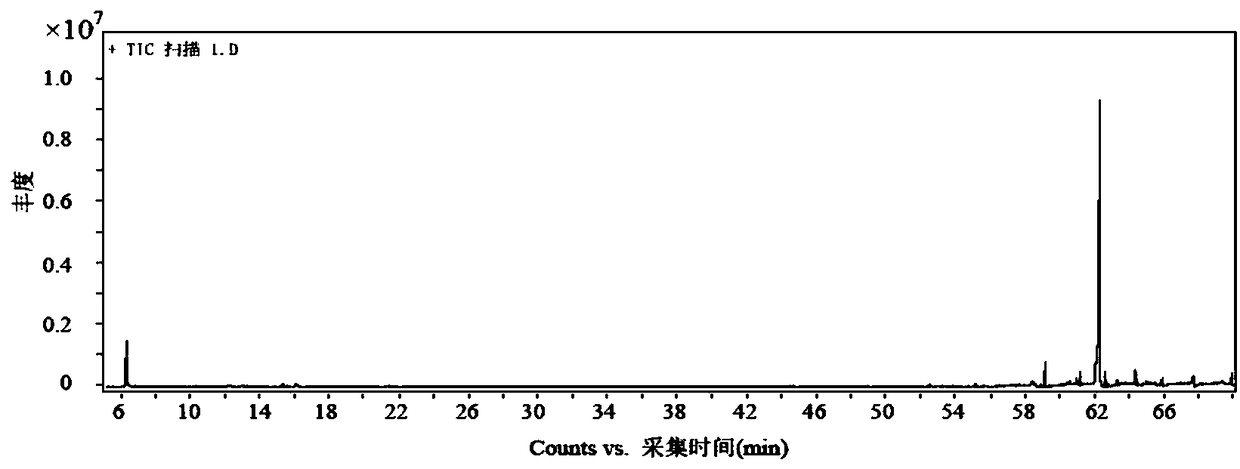

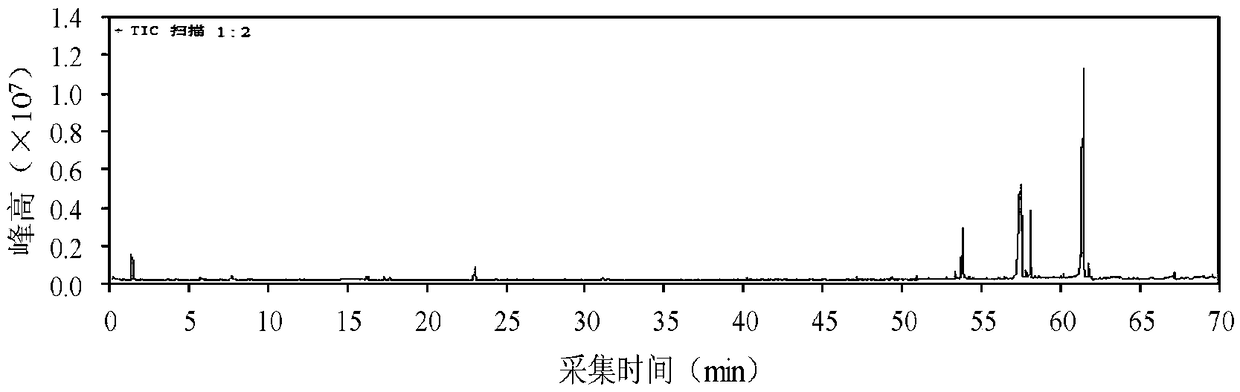

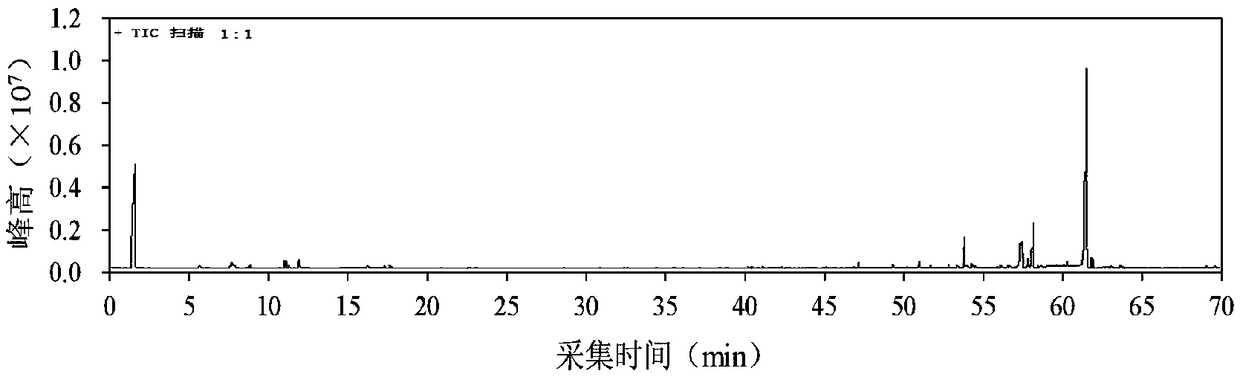

Image

Examples

preparation example Construction

[0032] The present invention provides the preparation method of the composite flavor enhancer described in the above scheme, comprising the following steps:

[0033] 1) Inoculate Aspergillus niger CGMCC No.3.316 into a liquid medium, and carry out shaking culture to obtain Aspergillus niger liquid;

[0034] 2) mixing ethyl maltol with a solvent in a ratio of 0.2 to 0.3 g: 100 mL to obtain ethyl maltol solution;

[0035] 3) Mix the Aspergillus niger liquid described in step 1) with the ethyl maltol solution described in step 2) at a volume ratio of 1:2 to 3:1 to obtain a composite flavor enhancer;

[0036] There is no chronological order between steps 1) and 2).

[0037] In the present invention, Aspergillus niger CGMCC No.3.316 is inoculated into the liquid medium, and cultured by shaking to obtain the Aspergillus niger liquid; the inoculation amount of the Aspergillus niger is preferably 0.4-0.6mL initial bacterial liquid / 75mL liquid medium , more preferably 0.5mL bacterium...

Embodiment 1

[0046] Embodiment 1 A kind of preparation method of composite flavor enhancer

[0047] 1) First configure the liquid medium, the liquid medium formula is: bran 3g, ammonium nitrate 0.5g, ferrous sulfate heptahydrate 0.5g, potassium dihydrogen phosphate 0.5g, calcium chloride 0.05g, magnesium sulfate heptahydrate 0.05g and distilled water 100mL;

[0048] 2) Inoculate Aspergillus niger CGMCCNo.3.316 into the liquid medium described in step 1) according to the ratio of 0.5mL / 75mL, and carry out shaking culture for 5 days at 25°C, initial pH 5.5, and 150rpm to obtain Aspergillus niger liquid ;

[0049] 3) Take 0.25g of ethyl maltol and place it in a glass container, add 100mL of water at 25°C to make a 0.25% ethyl maltol solution by volume and mass;

[0050] 4) Mix the Aspergillus niger liquid in step 2) and the ethyl maltol solution in step 3) uniformly at a volume ratio of 1:2 at 0°C to obtain a compound flavor enhancer.

Embodiment 2

[0051] Embodiment 2 A kind of preparation method of composite flavor enhancer

[0052] Referring to the preparation method of Example 1, except that the mixing volume ratio of Aspergillus niger liquid and ethyl maltol solution in step 4) is 1:1, other steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com