Five-axis linked numerical control laser cutting machine for hole edge of blister shell of helmet and process thereof

A five-axis linkage, CNC laser technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of unreasonable chip speed, easy to produce small steps, and low hardware cost, so as to improve competitiveness and edge Smooth, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

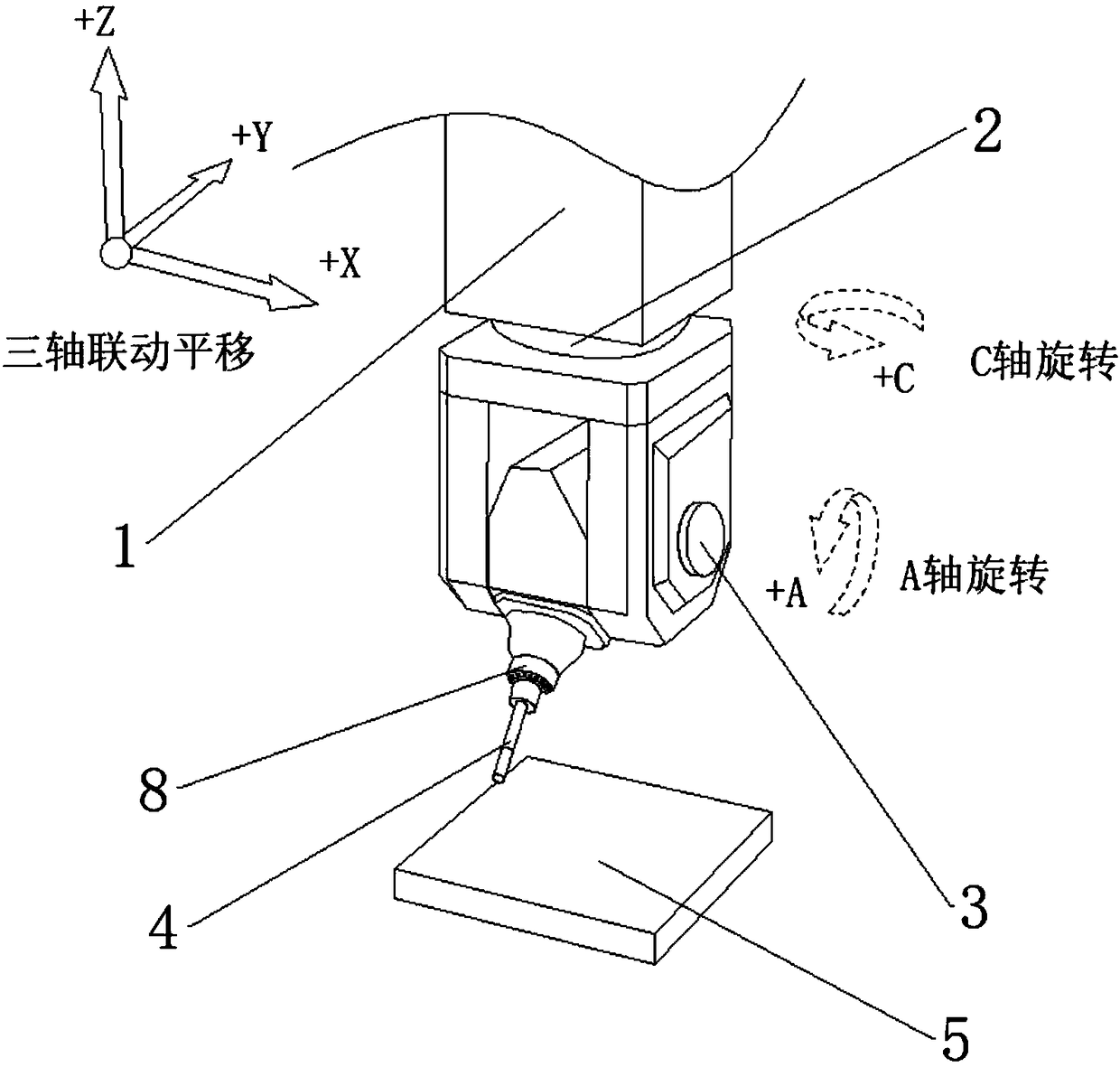

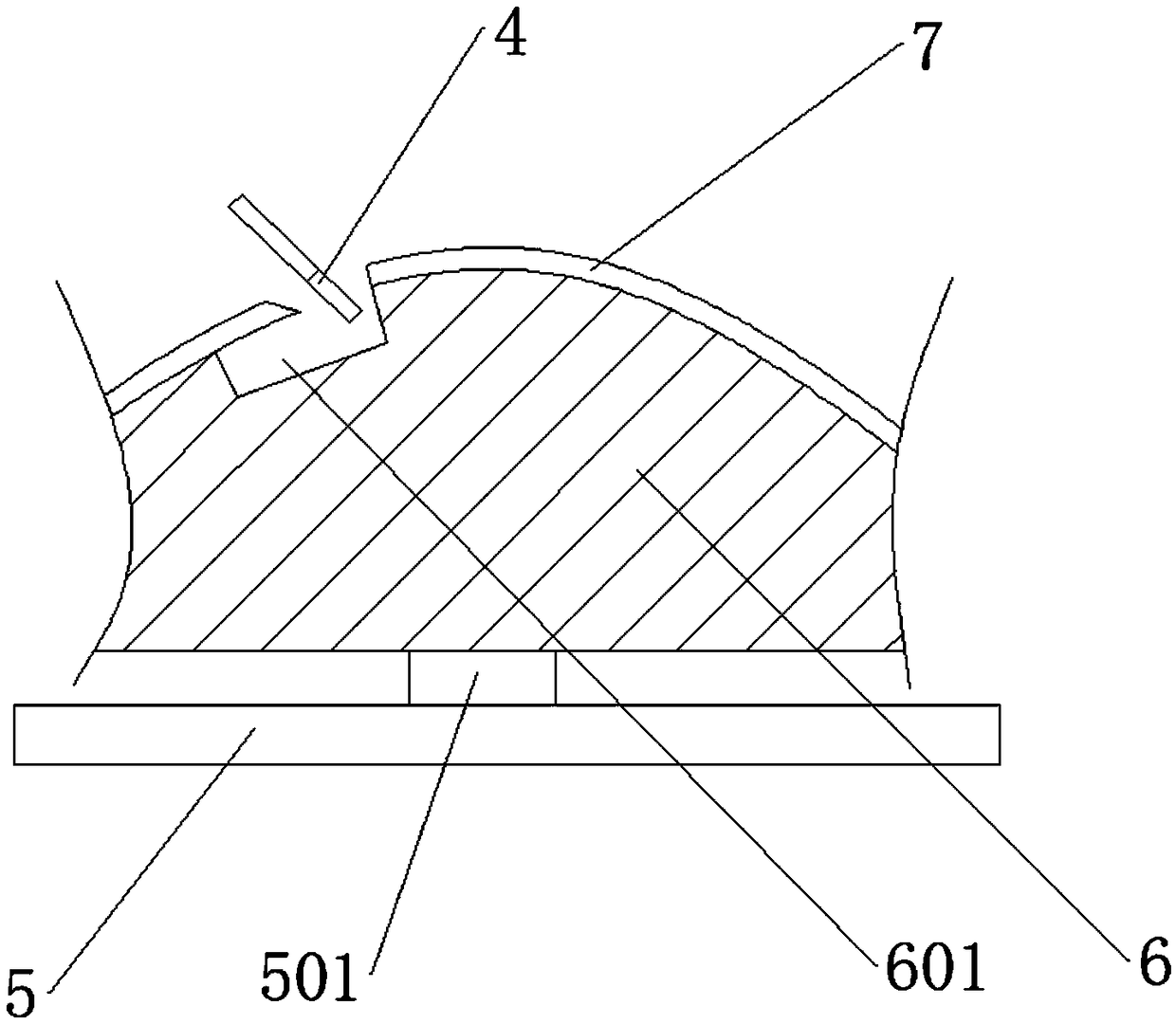

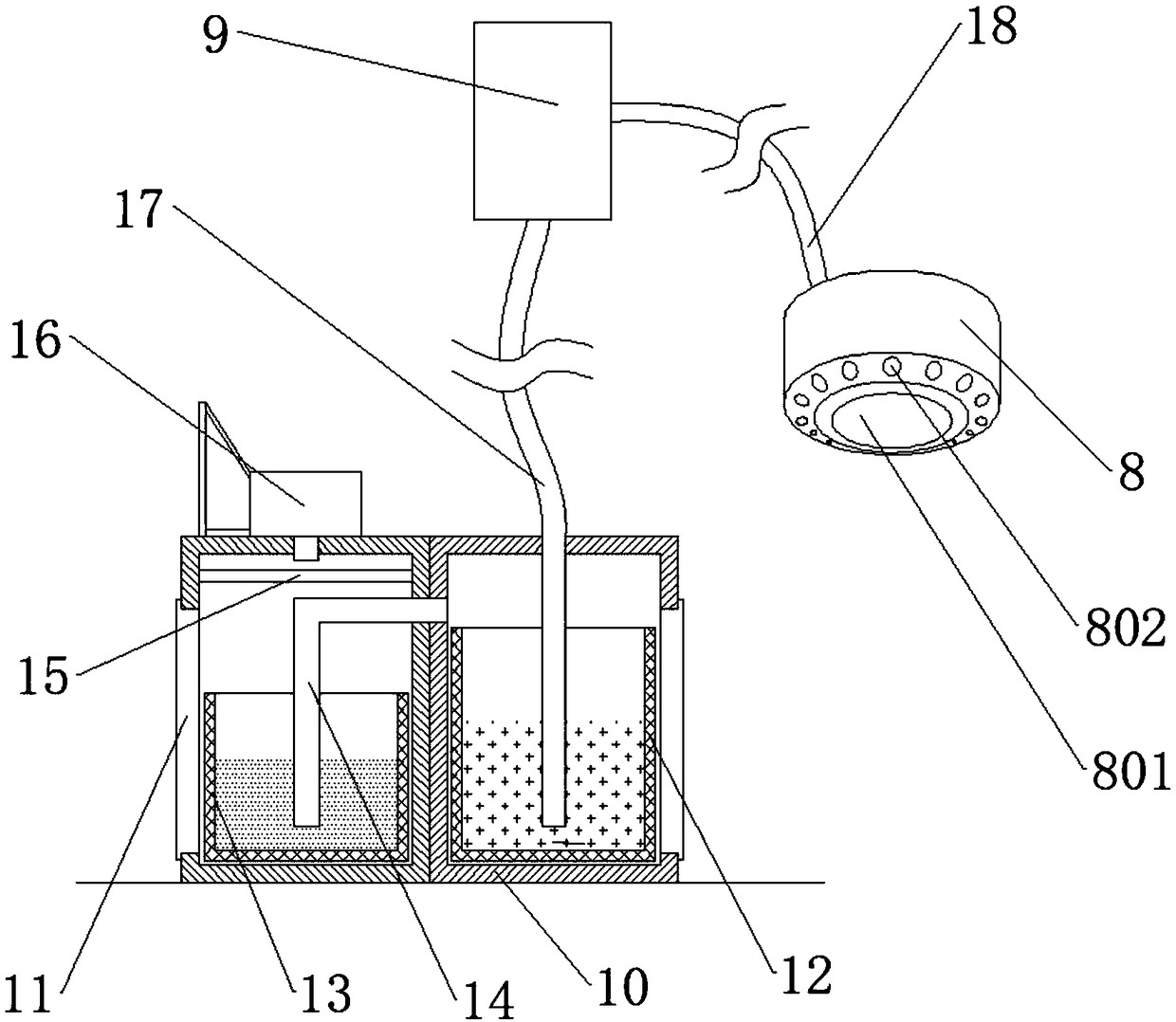

[0046] see Figure 1-2 , A five-axis linkage CNC laser cutting machine is used for the hole edge of the plastic shell of the helmet, including a workbench 5. The upper side of the workbench 5 is equipped with a spindle 1 that can translate along the X, Y and Z axes, and a carbon dioxide laser tube is installed inside the spindle 1. And the transmitter mirror, the lower end of the main shaft 1 is connected with the C-axis 2 that can rotate 360 degrees, the lower end of the C-axis 2 is connected with the A-axis 3 that can rotate around the X-axis, and the end of the A-axis 3 is connected with the laser cutting head 4. Laser cutting The head 4 includes a focusing mirror, and a blister positioning fixture 6 is placed on the workbench 5. An auxiliary fixture 501 is connected between the blister positioning fixture 6 and the workbench 5, and the blister positioning fixture 6 is fixed on the auxiliary fixture. On 501, a blister hole 601 is drilled on the blister positioning fixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com