Sampling method of glass fiber reinforced plastic anode of wet electrostatic precipitator in service

A wet electrostatic and FRP technology, applied in the direction of sampling devices, etc., can solve the problems of high hardness of FRP materials, narrow site space, difficult construction, etc., and achieve the effect of high repair strength, good stability, and convenient sampling and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

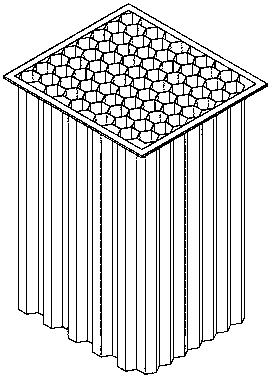

[0038] as attached figure 1 Shown, the sampling method of the FRP anode of wet electrostatic precipitator in service of the present invention, the method may further comprise the steps:

[0039] Step 1. Preparation of the repair board:

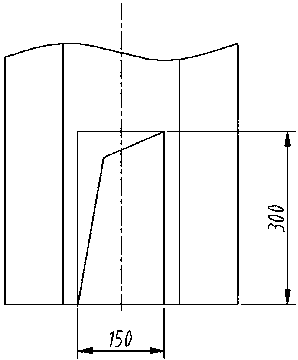

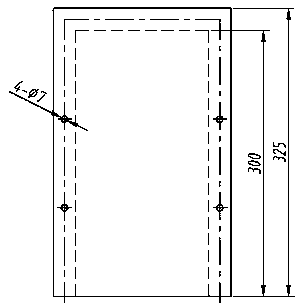

[0040] The anode thickness of the glass fiber reinforced plastic anode module of the wet electrostatic precipitator in service is 6mm, and a 12mm thick conductive glass steel plate is used. A 200×350mm flat plate is cut out by a CNC engraving machine, and then a three-sided guide groove is milled out by a desktop milling machine. The obtained repair plate is ready for use. , the repair plate structure is as image 3 , Figure 4 shown.

[0041] The width of the guide groove is 6.4mm to meet the assembly requirements of the anode surface after insertion of 6mm, and the thickness of the single side of the guide groove is about 2.8mm, which is to meet the strength requirements during assembly. The width of the repair plate is 200mm, which can ...

Embodiment 2

[0052]The thickness of the in-service FRP anode module is generally 6mm, and the thickness of the conductive FRP is selected as 10mm in this example. The depth of the guide groove is 25mm, the width of the guide groove is 6.4mm, and the wall thickness of one side of the guide groove is 1.8mm. All the other are the same as embodiment one.

[0053] Application implementation one:

[0054] The wet electrostatic precipitator of a 600MW unit in East China ushered in the first overhaul after four years of operation. During the inspection, it was found that many plates were delaminated and peeled off. The user needs to find out the strength retention rate of the material during the overhaul period to evaluate whether to continue to serve for one overhaul period.

[0055] The user entrusts a third-party testing unit to select four typical anode cylinders and cut them on the upper surface of the anode according to the sampling method of the present invention according to the requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com