Normal temperature heat conducting and high temperature insulation porcelainized high molecular material and preparation method of material

A technology of polymer materials and heat insulating fillers, which is applied in the field of porcelainizable polymer materials and their preparation, can solve the problem of difficulty in ensuring low temperature heat conduction and high temperature heat insulation at the same time, poor compatibility between heat conductive fillers and silicone rubber matrix, and composite materials. Mechanical properties have a great impact on problems such as easy mass production, excellent mechanical properties, and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

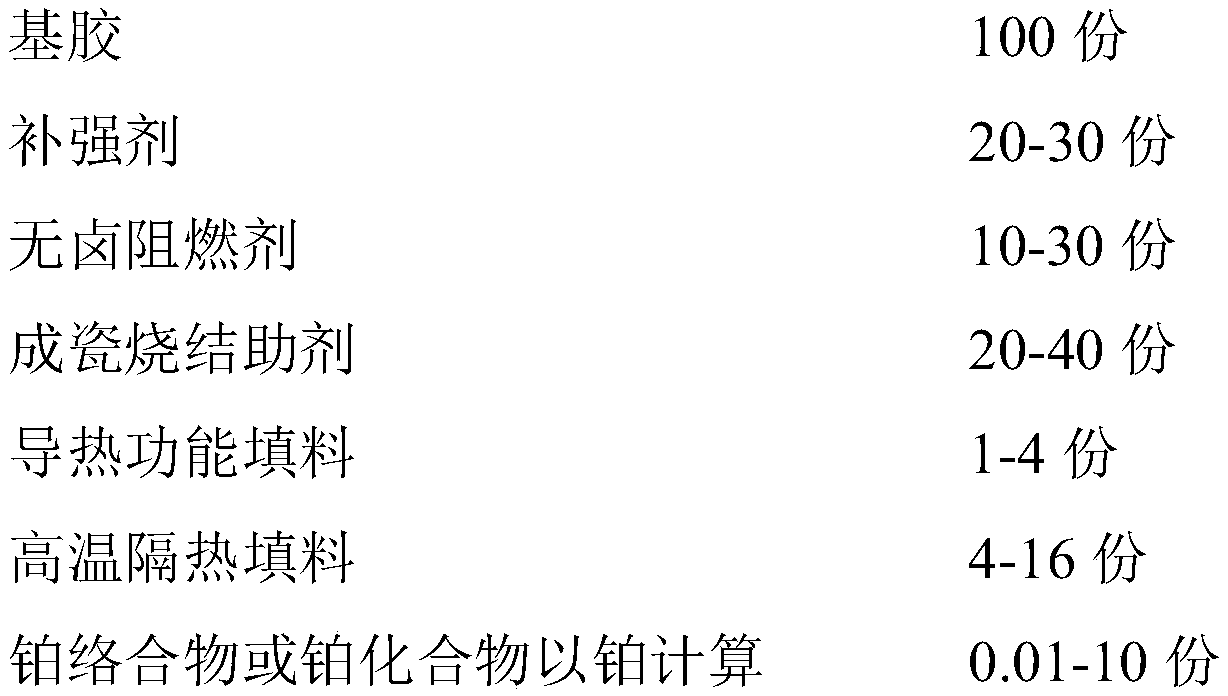

[0043] See attached Figure 1-2 , a normal temperature heat conduction-high temperature heat insulation ceramicizable polymer material provided by the present invention, which is prepared from the following raw material components (by mass fraction):

[0044]

[0045] The preparation method of the above normal temperature heat conduction-high temperature heat insulation ceramicizable polymer material comprises the following steps:

[0046] (1) Get aluminum hydroxide 1500g and deionized water 5000g, adopt zirconia ball milling beads 5000g as the grinding medium, import in the vertical sand mill and grind, the grinding time is 1 hour, and the grinding speed is 60 rpm;

[0047] (2) filter after grinding, use 300 mesh filter screens for filtration, get the solid gained from the filtration, dry and pulverize to obtain the aluminum hydroxide that has been pretreated;

[0048] (3) Base rubber mixing: use an internal mixer, add methyl vinyl silicone rubber, linear low-density poly...

Embodiment 2

[0053] A normal temperature heat conduction-high temperature heat insulation ceramicizable polymer material, which is prepared from the following raw material components (by mass fraction):

[0054]

[0055] The preparation method of the above normal temperature heat conduction-high temperature heat insulation ceramicizable polymer material comprises the following steps:

[0056] (1) Get each 1500g of magnesium hydroxide, sepiolite fiber and mix with deionized water 5000g respectively, respectively adopt 5000g of zirconia ball milling beads as the grinding medium, import in the vertical sand mill and grind, the grinding time is 1 hour, The grinding speed is 60 rpm;

[0057] (2) Filtrate after grinding, use a 300-mesh filter screen for filtration, take the solid obtained from the filtration, dry and pulverize, and obtain pretreated magnesium hydroxide and sepiolite fibers;

[0058] (3) Base rubber mixing: use an internal mixer, add methyl vinyl silicone rubber, linear low-d...

Embodiment 3

[0063] A normal temperature heat conduction-high temperature heat insulation ceramicizable polymer material, which is prepared from the following raw material components (by mass fraction):

[0064]

[0065]

[0066] A method for preparing a normal temperature heat conduction-high temperature heat insulation ceramicizable polymer material, comprising the following steps:

[0067] (1) get aluminum hydroxide, sepiolite fiber each 1500g and mix with deionized water 5000g respectively, respectively adopt zirconia ball milling beads 5000g as grinding medium, import in the vertical sand mill and grind, the grinding time is 1 hour, The grinding speed is 60 rpm;

[0068] (2) Filter after grinding, use a 300-mesh filter screen to filter, take the solid obtained from the filter, dry and pulverize, and obtain pretreated aluminum hydroxide and sepiolite fibers;

[0069] (3) Base rubber mixing: use an internal mixer, add methyl vinyl silicone rubber, linear low density polyethylene,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com