High-performance and environment-friendly nano-silicone acrylate outer wall coating and preparation method thereof

An exterior wall coating, nano-silicon technology, applied in the direction of coating, can solve the problems of high cost, low price, easy hydrolysis addition of organosiloxane modifiers, etc., and achieve better stability, low cost, and easy promotion. The effect of value and development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a modified resin substrate emulsion, comprising the following steps:

[0036] (1) Pre-emulsification treatment of vinyl silicone oil:

[0037] The solid content of the pre-emulsion in this embodiment is set to 40%. First, the thick emulsion containing vinyl silicone oil is prepared by inverse emulsification, and 40 parts of vinyl silicone oil is added to 2% (accounting for the mass ratio of vinyl silicone oil. ) compound emulsifier, put it into a two-necked flask, and carry out (1000r / min) high-speed stirring. When the emulsifier is completely dispersed in the vinyl silicone oil to form a paste, start to add 60 parts of water until it becomes evenly dispersed. Then the thick pre-emulsion was homogenized by a high-pressure homogenizer at a frequency of 25GMP for 15min, and then taken out and sealed for storage.

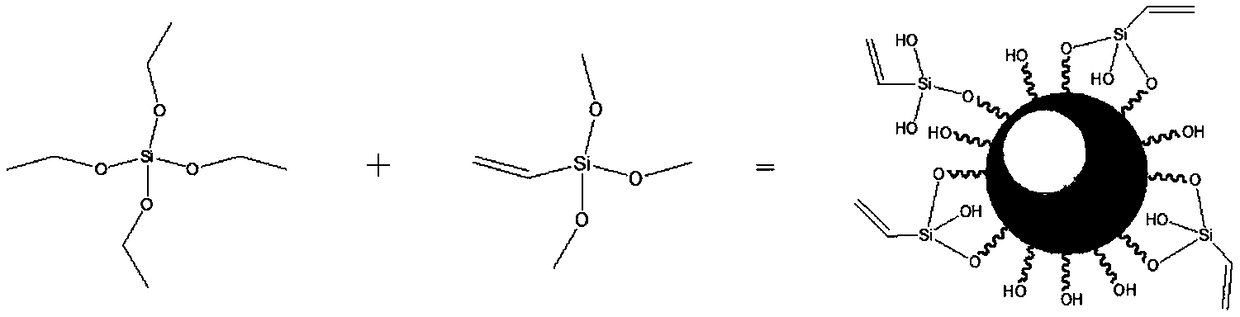

[0038] (2) Preparation of modified nanoparticles:

[0039] Dissolve a part of ethanol and hydrochloric acid (H...

Embodiment 2~4

[0049] Embodiments 2-4 provide the preparation method of high-performance environment-friendly nano-silicone-acrylic exterior wall paint. The modified resin substrate emulsion obtained in Example 1 is configured into an exterior wall paint according to the basic formula of the exterior wall paint. The basic proportions are shown in Table 1. Among them, the mass percentages of the modified resin substrate emulsion and water were changed between Examples 2 and 4 of the present invention, referring to the content of additives and pigments and fillers in the same mass percentage.

[0050] The specific preparation method is: according to the mass percentage of each formula given in Table 1, first add water, dispersant and other additives into the mixer, fully mix and stir evenly, and then add talcum powder, bentonite, titanium dioxide and light calcium carbonate, etc. Pigment, mix and stir evenly. Transfer to the grinder to depolymerize and disperse the secondary particles of pigme...

Embodiment 5

[0054] Embodiment 5 performance test

[0055] The exterior wall paint prepared in the above-mentioned Examples 2 to 4 and the commercially available silicone acrylic exterior wall paint were compared and tested in strict accordance with the "Preparation of Architectural Paint Coating Test Panels" (JG / T23-2001) , and the test results are shown in Table 4.

[0056] Table 4 Comparative test results of exterior wall coatings

[0057]

[0058]

[0059] It can be concluded from the test results that at the present stage, my country's buildings are developing towards large-scale and high-rise buildings. As a traditional building exterior wall coating, pure acrylic coatings are easy to stick back at high temperatures and brittle at low temperatures. Poor and other shortcomings, it has been unable to meet the needs of weather resistance, stain resistance, high color retention and low pollution performance. In view of the above shortcomings, the high-performance nano-environmental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com