Culture method of lactic acid bacteria for feed

A culture method and technology of lactic acid bacteria, applied in the field of microorganisms, to achieve the effects of improving acid stress resistance and reproduction number, convenient operation and good culture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] For the cultivation method of lactic acid bacteria for feed, the inoculation amount of the seed liquid is 1.8v / v%. The activated Lactobacillus seed liquid for feed is inoculated into the fermentation medium containing whey protein hydrolyzate. Fermenting and culturing at 100 rpm for 14 hours to obtain a lactobacillus fermentation liquid for feeding; wherein the whey protein hydrolyzate is obtained by acid hydrolyzing whey protein added with inulin in hydrochloric acid solution containing D-configuration acid.

[0038] The above fermentation medium contains whey protein hydrolyzate 20g / L, yeast powder 2g / L, glucose 14g / L, buffer salt 5g / L, Mg 2+ Water-soluble compound 0.3g / L, Fe 2+ Water-soluble compound 0.1g / L, MnSO 4 0.04g / L; Mg 2+ The water soluble compound is MgSO 4 ; 2+ The water soluble compound is FeSO 4 ; Wherein; Buffer salt is sodium citrate.

[0039] The above inulin has a degree of polymerization of 15; the inulin contains 2.7% of gamma-inulin.

[0040...

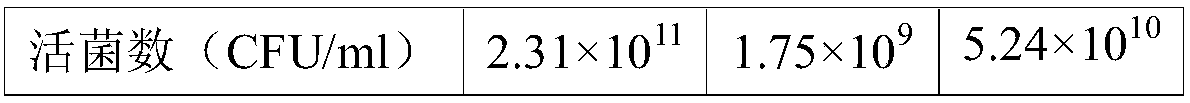

Embodiment 2

[0042] For the cultivation method of lactic acid bacteria for feed, the inoculum amount of the seed liquid is 2.05v / v%. The activated Lactobacillus seed liquid for feed is inoculated into the fermentation medium containing whey protein hydrolyzate. Fermentation was carried out at 110rpm for 15 hours to obtain a lactobacillus fermentation liquid for feeding; wherein the whey protein hydrolyzate was obtained by acid hydrolyzing whey protein added with inulin in a hydrochloric acid solution containing D-configuration acid.

[0043] The above fermentation medium contains whey protein hydrolyzate 26g / L, yeast powder 4g / L, glucose 20g / L, buffer salt 7.5g / L, Mg 2+ Water-soluble compound 0.4g / L, Fe 2+Water-soluble compound 0.2g / L, MnSO 4 0.05g / L; Mg 2+ The water soluble compound is MgCl 2 ; 2+ The water soluble compound is FeCl 2 ; Wherein the buffer salt is potassium dihydrogen phosphate, sodium citrate and sodium acetate in a weight ratio of 1:0.8:0.4.

[0044] The degree of p...

Embodiment 3

[0047] For the cultivation method of lactic acid bacteria for feed, the inoculation amount of the seed liquid is 2.3v / v%. The activated Lactobacillus seed liquid for feed is inoculated into the fermentation medium containing whey protein hydrolyzate. The fermented culture was carried out at 120rpm for 16 hours to obtain a lactobacillus fermentation liquid for feeding; wherein the whey protein hydrolyzate was obtained by hydrolyzing the whey protein added with inulin with hydrochloric acid solution containing D-configuration acid.

[0048] The above fermentation medium contains whey protein hydrolyzate 32g / L, yeast powder 6g / L, glucose 25g / L, buffer salt 10g / L, Mg 2+ Water-soluble compound 0.5g / L, Fe 2+ Water-soluble compound 0.3g / L, MnSO 4 0.06g / L; Mg 2+ The water soluble compound is MgCO 3 ; 2+ The water soluble compound is (NH 4 ) 2 Fe(SO 4 ) 2 ; Wherein the buffer salt is calcium carbonate.

[0049] The above-mentioned inulin has a degree of polymerization of 18; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com