Nano composite adsorbent as well as preparation method and application thereof

A nano-composite material and adsorbent technology, applied in the field of materials, can solve the problems of poor adsorption stability, poor selectivity, slow adsorption speed, etc., and achieve the effects of high adsorption capacity, fast adsorption speed, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

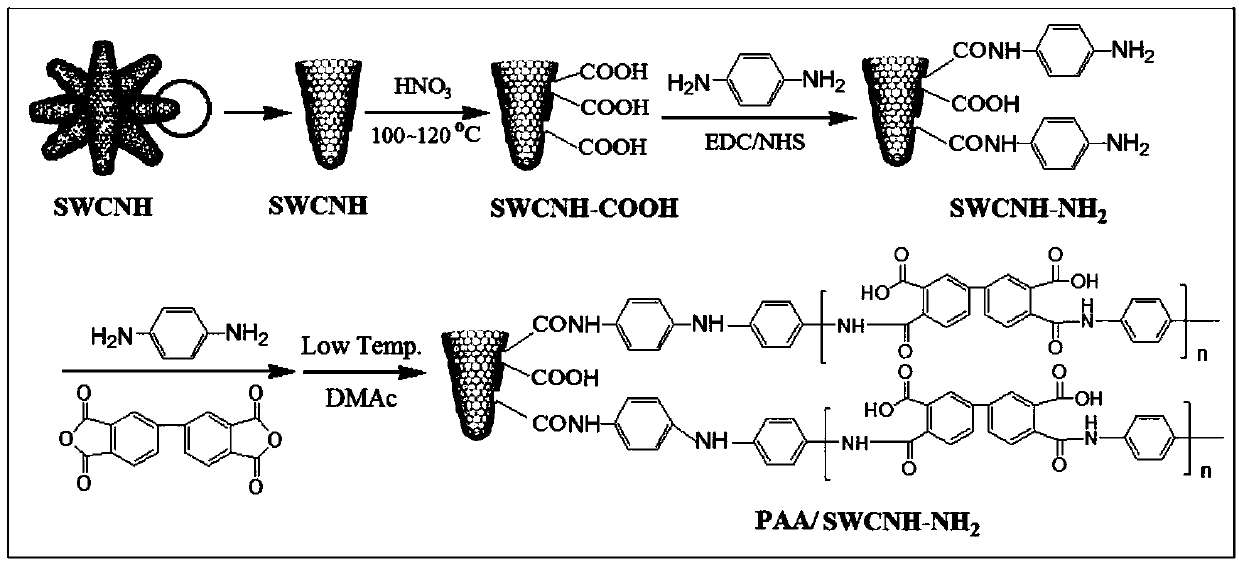

[0030] Such as figure 1 Shown, the PAA / SWCNH-NH of the present invention 2 The preparation method of nanocomposite adsorbent comprises the following steps:

[0031] Step 1: Modification of SWCNH (SWCNH-COOH)

[0032] Disperse 100-200 mg of SWCNH into 200-300 mL of nitric acid solution and reflux at 100-120 ° C for 24-30 hours to obtain a carboxylated SWCNH dispersion, which is centrifuged, washed and filtered with deionized water for several times until the filtrate becomes Neutralize, then vacuum dry, then disperse the carboxylated single-walled carbon nanohorns in deionized water, and make a dispersion of 0.5-1.0 mg / mL for use;

[0033] Step 2: p-phenylenediamine functionalized SWCNH (SWCNH-NH 2 )

[0034] Carboxylated single-walled carbon nanohorns and p-phenylenediamine are used as reaction raw materials, and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide are used as reaction materials. Catalyst, under the protection of nitrogen, ...

Embodiment 2

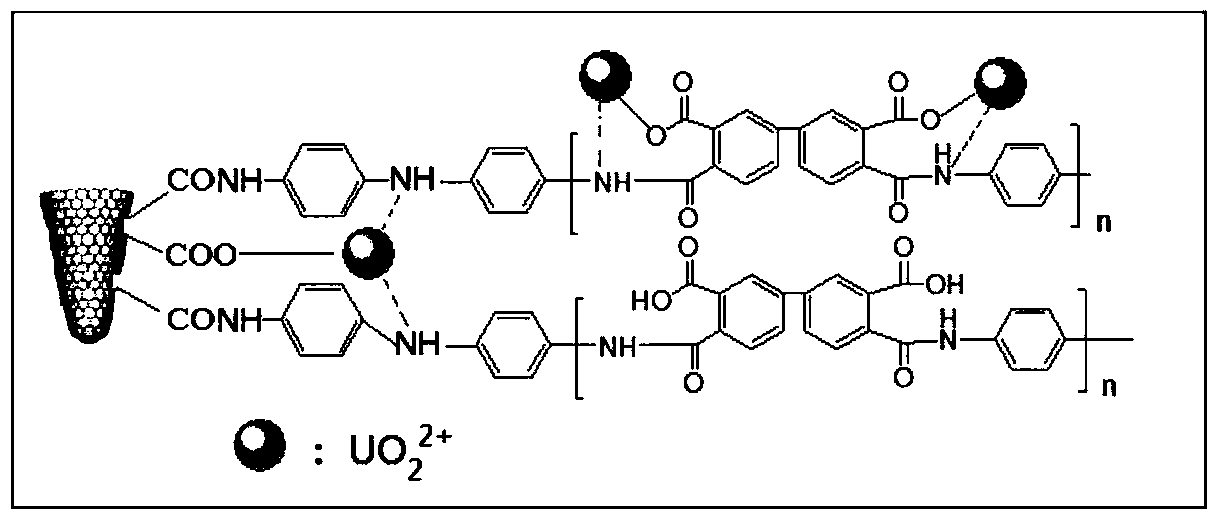

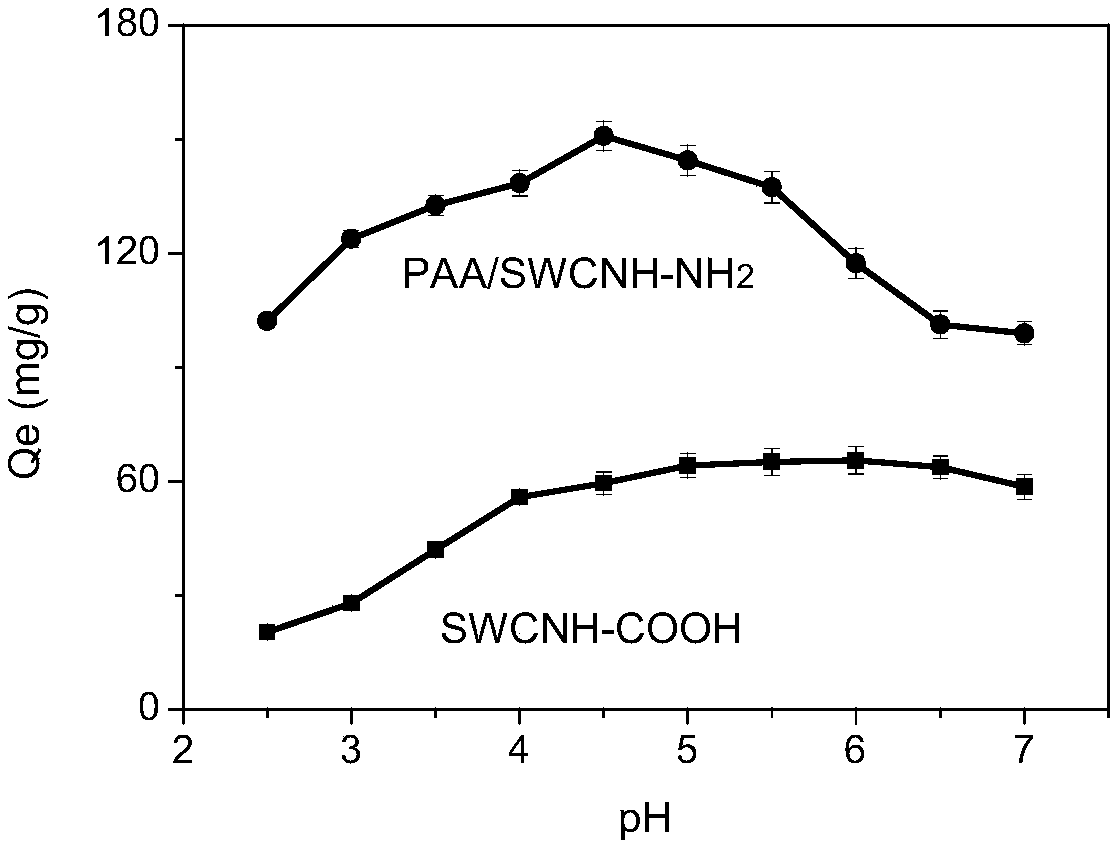

[0038] The present invention also provides a kind of said PAA / SWCNH-NH 2 The nanocomposite adsorbent is used as a method for separating and enriching uranium, and its specific operation is as follows:

[0039]Adjust the hydrogen ion concentration (pH value) of the uranium-containing aqueous solution to be treated, then add an adsorbent, shake, and adsorb, wherein the concentration of the uranium-containing aqueous solution is 50 mg / L, the pH value range is between 2.5 and 7.0, and the oscillation speed is 90 ~120r / min. The adsorption temperature is 25°C, and the adsorption time is 20-200 minutes. The adjustment of the pH value uses 1 to 10 mol / L of HNO 3 solution, and 1-5 mol / L NaOH solution to adjust the pH of the solution. The absorbance was measured by Arsenazo III method, the concentration of uranium in the solution before and after adsorption was analyzed, and the adsorption amount of uranium was calculated to calculate the adsorption amount.

[0040] This embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com