Crystalline composite material and concrete waterproof material

A technology of composite materials and waterproof materials, applied in the field of waterproof materials, can solve the problems of poor waterproof effect, insufficient impermeability and compressive strength, etc., achieve good stability and practicability, improve impermeability, and good waterproof performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation of material A, cesium stearate, cesium chloride, sodium citrate, calcium carbonate, sodium carbonate, sodium silicate, beryllium carbonate, sodium bicarbonate, calcium metaaluminate, calcium chloride are carried out batching, raw material is pure Substance (content greater than 99.9%), wherein the average particle size of the solid phase powder is 10 microns, the raw materials are mixed in a mixer, and then the evenly stirred powder is dried at 130°C, and then sieved after drying, and sieved The mesh is 200 mesh, and then put into a roasting furnace for roasting, the roasting temperature is 230°C, and finally the roasted product is put in a grinder to make the powder particle size reach 12 microns;

[0026] For the preparation of material B, D-malic acid, L-malic acid, cesium tartrate, tartaric acid, sodium malate, and calcium metaaluminate are used as ingredients. The raw materials are pure substances (content greater than 99.9%), and the average particl...

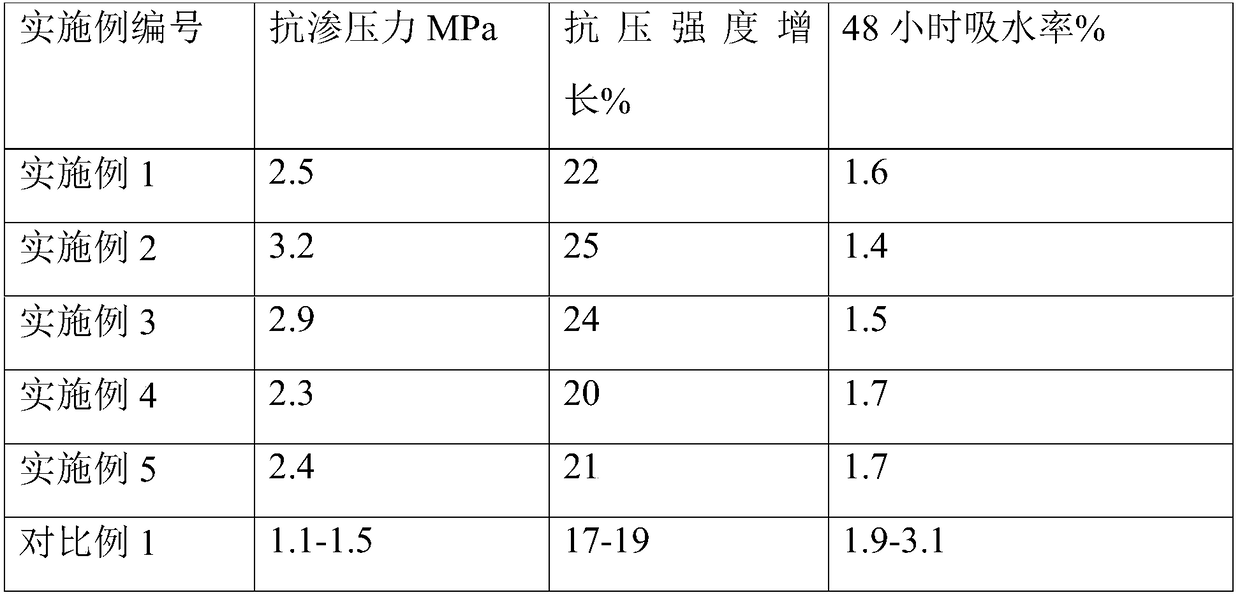

Embodiment 1

[0030] The waterproof material is prepared according to the above-mentioned preparation method, wherein, the crystalline composite material is compounded by material A, material B and material C according to a weight ratio of 10:1:0.1; the weight percentage content of each component in the material A is: Cesium Stearate 0.5%, Cesium Chloride 2%, Sodium Citrate 3%, Calcium Carbonate 2%, Sodium Carbonate 0.3%, Sodium Silicate 5%, Beryllium Carbonate 0.1%, Sodium Bicarbonate 0.3%, Calcium Metaaluminate 35% and the balance of calcium chloride; the weight percentage content of each component in the material B is: D-malic acid 1.8%, L-malic acid 2.5%, cesium tartrate 0.9%, tartaric acid 16%, sodium malate 2% and the balance of calcium metaaluminate; in material C, the weight ratio of stone resin and cesium carbonate is 1:0.08; relative to 100 parts by weight of Portland cement, the amount of the crystalline composite material is 0.3 parts by weight, so The consumption of the sodium ...

Embodiment 2

[0032]The waterproof material is prepared according to the above-mentioned preparation method, wherein, the crystalline composite material is compounded by material A, material B and material C according to a weight ratio of 10:2.5:0.3; the weight percentage content of each component in the material A is: Cesium Stearate 0.9%, Cesium Chloride 6%, Sodium Citrate 5%, Calcium Carbonate 4%, Sodium Carbonate 0.6%, Sodium Silicate 7%, Beryllium Carbonate 0.3%, Sodium Bicarbonate 0.6%, Calcium Metaaluminate 38% and the remainder calcium chloride; the weight percent content of each component in the material B is: D-malic acid 2.2%, L-malic acid 2.7%, cesium tartrate 1.2%, tartaric acid 17%, sodium malate 6% and the balance of calcium metaaluminate; in material C, the weight ratio of stone resin and cesium carbonate is 1:0.1; relative to 100 parts by weight of Portland cement, the amount of the crystalline composite material is 0.4 parts by weight, so The consumption of the sodium sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com