Ladle slag feather edge brick of waste submersed nozzle slag line sludge material

A ladle slag line and immersion technology, which is applied in the field of ladle slag line bricks, can solve the problems of increasing raw material costs, increasing procurement costs, and limited improvement potential, so as to improve the ability to resist steel slag erosion and peeling off, and reduce replacement and repair The workload, convenient operation and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

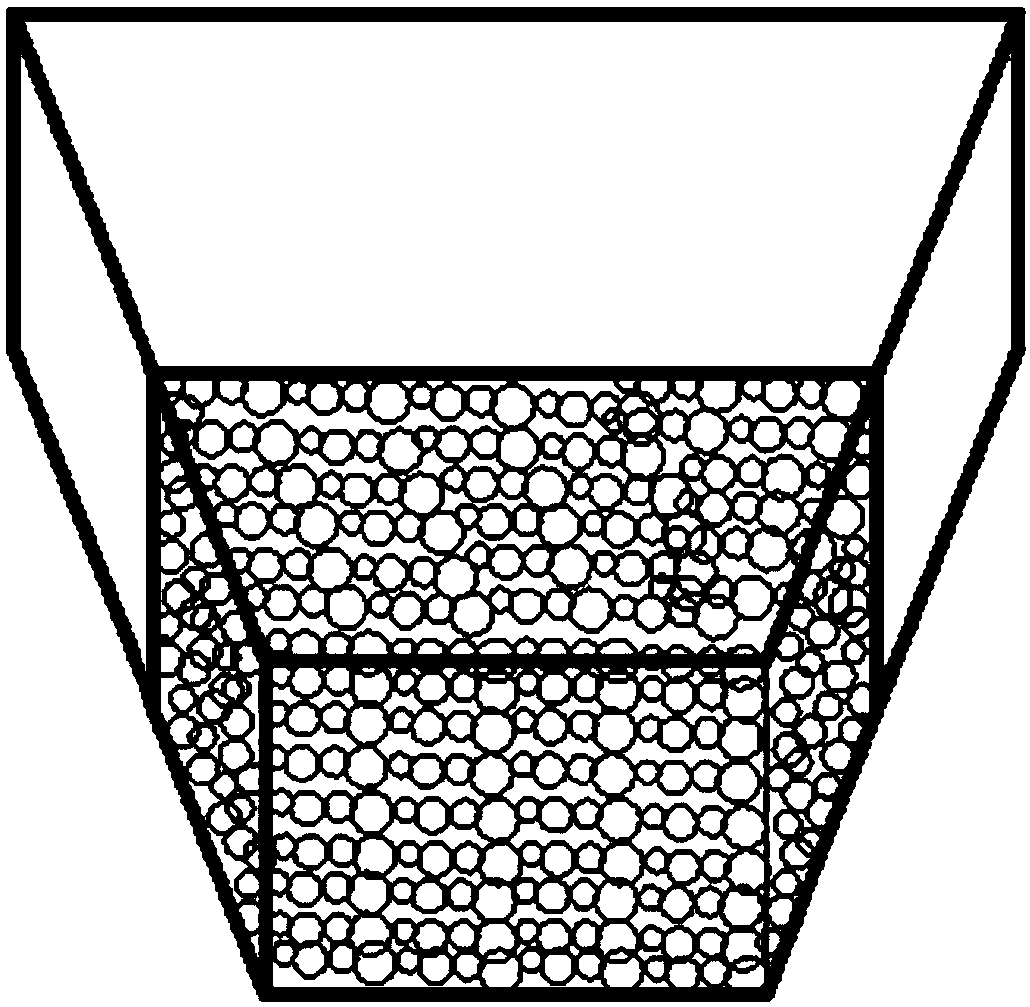

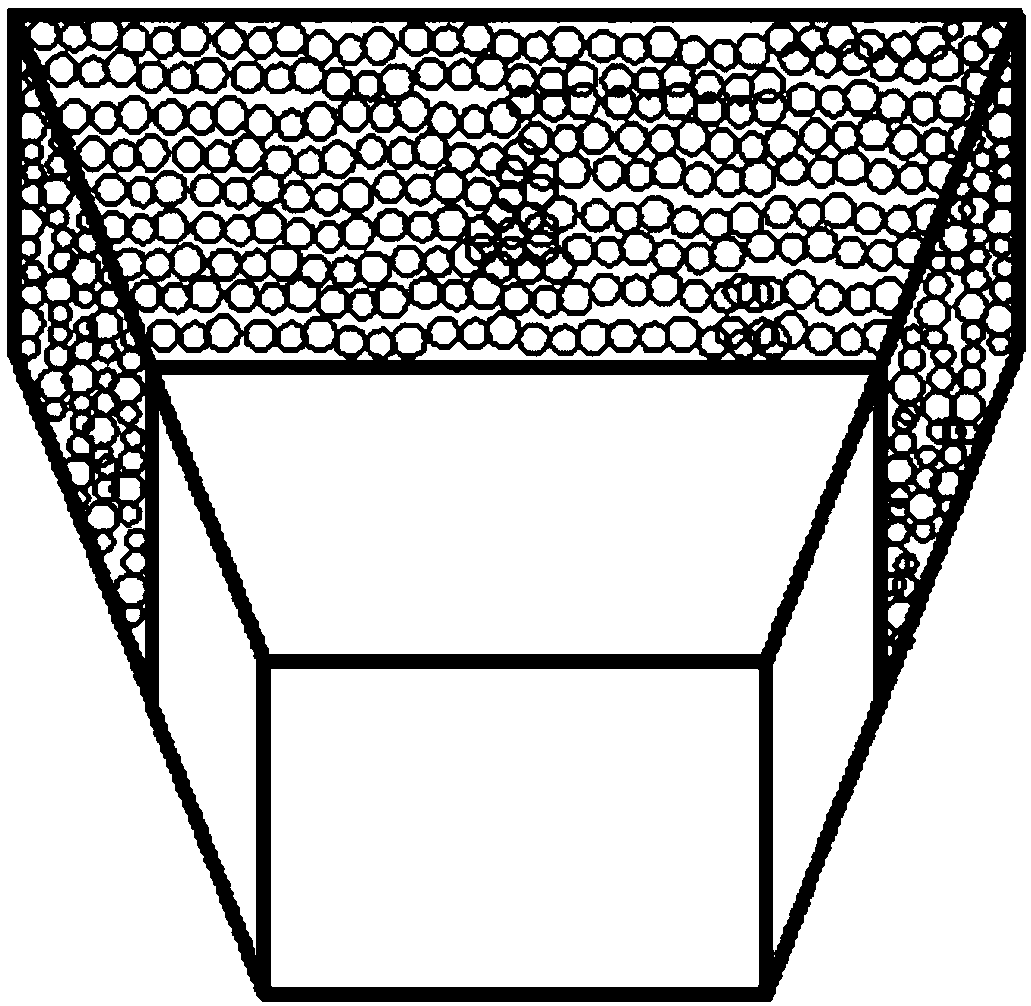

Image

Examples

example 1

[0041] A ladle slag line brick made of waste submerged nozzle slag line material, the mud material added with waste submerged nozzle slag line material is made of the following components: 96% magnesia 1-3mm25%, 96% magnesium Sand 0-1mm15%, waste submerged nozzle slag line broken material 0-0.21mm45%, metal silicon powder 1.5%, boron carbide 2%, aluminum powder 1%, carbon black 0.5%, graphite 6%, phenolic resin powder 1% , Liquid resin 6%.

[0042] The development method comprises steps as follows:

[0043] 1) 96% magnesia 1-3mm25%, 96% magnesia 0-1mm15%, waste submerged nozzle slag line broken material 0-0.21mm45%, metal silicon powder 1.5%, boron carbide 2%, according to the above ratio The raw materials were put into a mixer and kneaded for 30 minutes.

[0044] 2) Add 1% of aluminum powder, 0.5% of carbon black, and 6% of graphite, and put the raw materials into a mixer according to the above proportions and knead for 60 minutes.

[0045] 3) Then add 1% phenolic resin po...

example 2

[0051] A ladle slag brick made of waste submerged nozzle slag line material. The mud material added with waste submerged nozzle slag line material is made of the following components: 96% magnesia 1-3mm20%, 96% magnesia 0- 1mm10%, waste submerged nozzle slag line broken material 0-0.21mm55%, metal silicon powder 1%, boron carbide 1.5%, aluminum powder 1%, carbon black 1%, graphite 5%, phenolic resin powder 0.5%, liquid resin 6%.

[0052] The development method comprises steps as follows:

[0053] 1) 96% magnesia 1-3mm20%, 96% magnesia 0-1mm10%, waste submerged nozzle slag line broken material 0-0.21mm55%, metal silicon powder 1%, boron carbide 1.5%, according to the above ratio The raw materials were put into a mixer and kneaded for 30 minutes.

[0054] 2) 1% of aluminum powder, 1% of carbon black, and 5% of graphite, according to the above proportions, put the raw materials into a mixer and knead for 60 minutes.

[0055] 3) Then add 0.5% of phenolic resin powder and 6% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com