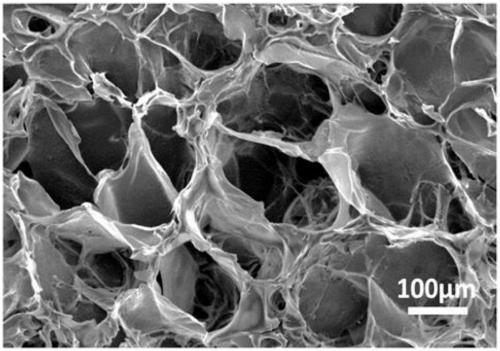

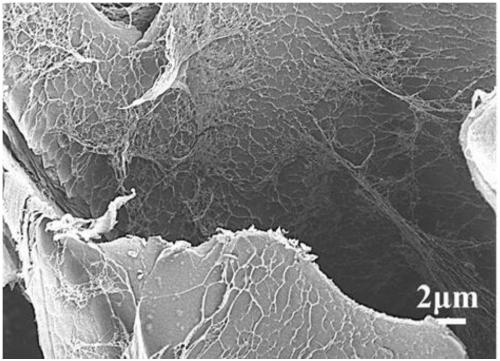

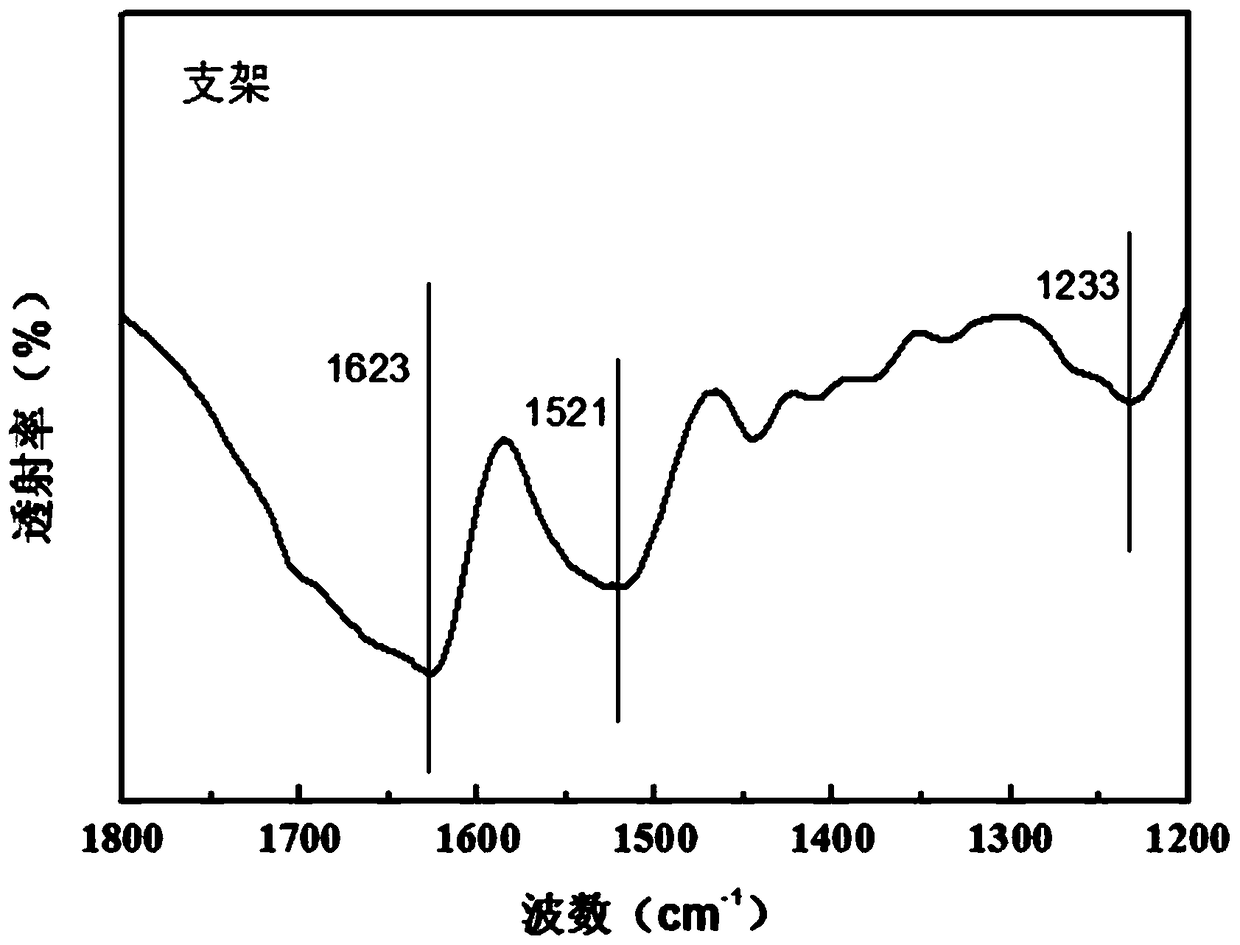

Silk fibroin three-dimensional porous scaffold and preparation method thereof

A three-dimensional porous, silk fibroin technology, applied in medical science, prosthesis, etc., can solve the problems of inability to transport and absorb nutrients, poor water absorption and water retention performance of gel film, poor processability, etc., and achieve good biocompatibility. high water absorption, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) degumming: the silk fiber is placed in the Na that mass fraction is 0.05wt% 2 CO 3 Boil in an aqueous solution for 30 minutes, wash thoroughly with deionized water, repeat the above process three times, dry in an oven at 60°C for 24 hours, and loosen for later use;

[0035] (2) Melting silk: Weigh and measure CaCl respectively 2 and formic acid (purity greater than 98%), the preparation of salt concentration is 30g / L of CaCl 2 -Formic acid solution, weigh 3g silk fibroin and add 100mL CaCl 2 - Manually shake in the formic acid solution for 10-30 minutes, and let stand at room temperature for 1 hour to obtain the silk fibroin solution;

[0036] (3) Dissolving sugar: Weigh 2 g of hyaluronic acid and add it to the silk fibroin solution, shake it manually, and let it stand at room temperature for 3 hours to obtain a silk fibroin polysaccharide blend solution;

[0037] (4) Preparation of silk fibroin hydrogel: inject the above-mentioned silk fibroin proteoglycan blen...

Embodiment 2

[0040] (1) degumming: the silk fiber is placed in the Na that mass fraction is 0.05wt% 2 CO 3 Boil in an aqueous solution for 30 minutes, wash thoroughly with deionized water, repeat the above process three times, dry in an oven at 60°C for 24 hours, and loosen for later use;

[0041] (2) Melting silk: Weigh and measure CaCl respectively 2 and formic acid (purity greater than 98%), the preparation of salt concentration is 100g / L of CaCl 2 -Formic acid solution, weigh 6g silk fibroin and add 100mL CaCl 2 - Manually shake in the formic acid solution for 10-30 minutes, and let stand at room temperature for 1 hour to obtain the silk fibroin solution;

[0042] (3) Dissolving sugar: Weigh 5g of hyaluronic acid and add it to the silk fibroin solution, shake it manually, and let it stand at room temperature for 3 hours to obtain a silk fibroin polysaccharide blend solution;

[0043] (4) Preparation of silk fibroin hydrogel: inject the above-mentioned silk fibroin proteoglycan blen...

Embodiment 3

[0046] (1) degumming: the silk fiber is placed in the Na that mass fraction is 0.05wt% 2 CO 3 Boil in an aqueous solution for 30 minutes, wash thoroughly with deionized water, repeat the above process three times, dry in an oven at 60°C for 24 hours, and loosen for later use;

[0047] (2) Melting silk: Weigh and measure CaCl respectively 2 and formic acid (purity greater than 98%), the preparation of salt concentration is 50g / L of CaCl 2 -Formic acid solution, weigh 10g silk fibroin and add 100mL CaCl 2 - Manually shake in the formic acid solution for 10-30 minutes, and let stand at room temperature for 1 hour to obtain the silk fibroin solution;

[0048] (3) Dissolving sugar: Weigh 5g of hyaluronic acid and add it to the silk fibroin solution, shake it manually, and let it stand at room temperature for 3 hours to obtain a silk fibroin polysaccharide blend solution;

[0049] (4) Preparation of silk fibroin hydrogel: inject the above-mentioned silk fibroin proteoglycan blen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com