A tower climbing structure

A technology for towers and support rods, which is applied in building construction, construction, coating, etc., can solve the problems of poor chemical stability of composite insulating paint, poor electrical insulation strength, and wrinkled surface of paint film, so as to reduce manpower input and reduce insulation. Excellent performance and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

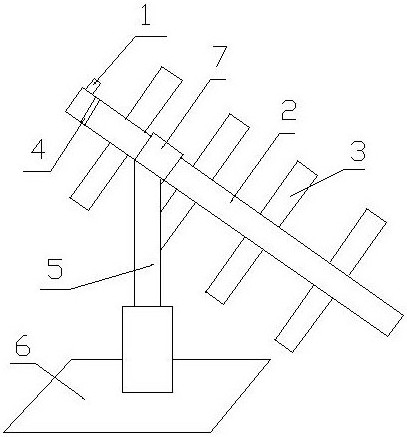

[0024] refer to figure 1 , this embodiment provides a pole tower climbing structure, including a pillar 2, several pedals 3 arranged on the pillar 2 and a support mechanism arranged on one side of the pillar 2; the support mechanism includes a support 6 And the support rod 5 arranged on the support 6, the end of the support rod 5 is provided with a fastener 7 for fixing the pillar 2, and the upper end of the pillar 2 is provided with a card slot 4 and a safety hook 1 , the card slot 4 is located at the lower part of the safety hook 1 .

[0025] Wherein, the pillar 2, the pedal 3, the support rod 5 and the bearing 6 are all made of stainless steel. The pedal 3 is welded on both sides of the pillar 2 symmetrically, so that the balance is good. The bearing 6 is fixed on the ground by ground piles, the support rod 5 is vertically welded on the upper part of the bearing 6, and the other end of the support rod 5 is provided with a fastener 7 to fix the pillar 1, and the fastener 7...

Embodiment 2

[0027] The insulating varnish provided in this example is prepared from the following components by weight: 3 parts of 3-dimethylaminopropylamine, 5 parts of sodium methyl silicate, 1 part of silane coupling agent KH570, and 3 parts of antioxidant T502 , 4 parts of filler, 30 parts of epoxy resin, 15 parts of acrylic resin, 6 parts of dicyclopentadiene, 22 parts of ethanol, 20 parts of acetone, and 35 parts of water.

[0028] The filler is a mixture of boron nitride, silicon carbide and vermiculite powder, the weight ratio of boron nitride: silicon carbide: vermiculite powder is 1:3:4, and the particle size is 200 mesh.

Embodiment 3

[0030] The insulating varnish provided in this example is prepared from the following components by weight: 3.5 parts of trimethylhexamethylenediamine, 6 parts of ammonium zirconium carbonate, 1.6 parts of titanate coupling agent 131, and antioxidant 2246 4 parts, 5 parts of filler, 32 parts of epoxy resin, 18 parts of acrylic resin, 6.5 parts of dicyclopentadiene, 25 parts of ethanol, 22 parts of acetone, 36 parts of water.

[0031]The filler is a mixture of boron nitride, silicon carbide and vermiculite powder, the weight ratio of boron nitride: silicon carbide: vermiculite powder is 1:4:5, and the particle size is 250 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com