Cover plate glass pool furnace flue gas treatment system

A technology of flue gas treatment system and cover glass, which is applied in the direction of gas treatment, separation method, and separation of dispersed particles, etc., which can solve the problems of high cost of use, incomplete out-of-stock, and difficulty in treating waste gas sulfides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

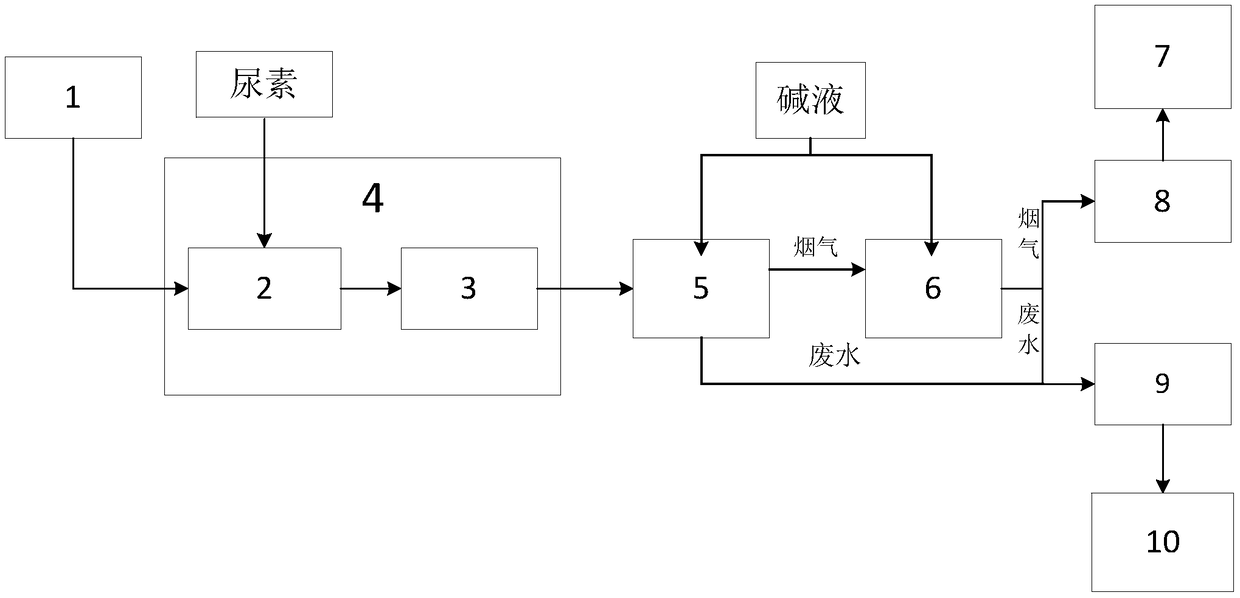

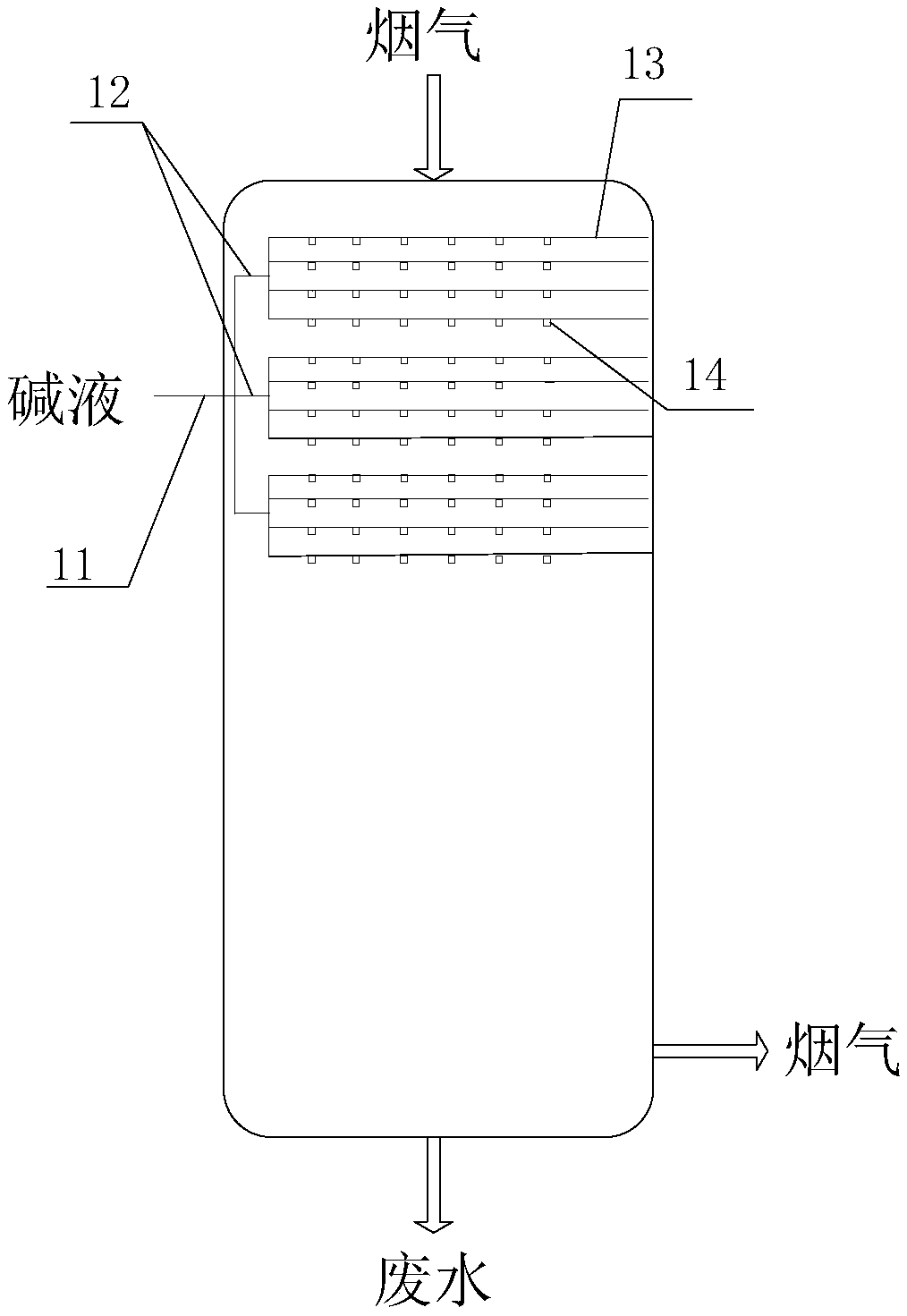

[0031] see figure 1 The invention discloses a cover glass flue gas treatment system, comprising an SCR system 4, a cooling circulation tower 5, an absorption circulation tower 6, a chimney 7, a fan 8, a centrifuge 9 and a waste water treatment system 10; the SCR system 4 includes a mixing device 2 and the reaction device 3; the mixing device 2 is provided with a urea spray gun, and the reaction device 3 is provided with a honeycomb catalyst; the cooling cycle tower 5 is provided with a first spray device, and the absorption cycle tower 6 is provided with a second spray device , the structure of the first spraying device and the second spraying device is the same, each spraying device is provided with a lye input main pipeline 11, a primary branch 12, a secondary branch 13 and a shower head 14.

[0032] The flue gas output port of the glass kiln 1 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com