Cation exchange membrane for electrodialytic treatment of ammonium and nitrogen waste water and preparation method thereof

A technology of cation exchange membrane and ammonia nitrogen wastewater, which is applied in the field of cation exchange membrane and preparation for the treatment of ammonia nitrogen wastewater by electrodialysis, can solve the problems of short service life, decreased ammonia nitrogen removal ability and mechanical properties, poor durability, etc. Chemical production, high ammonia nitrogen removal efficiency, good recycling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

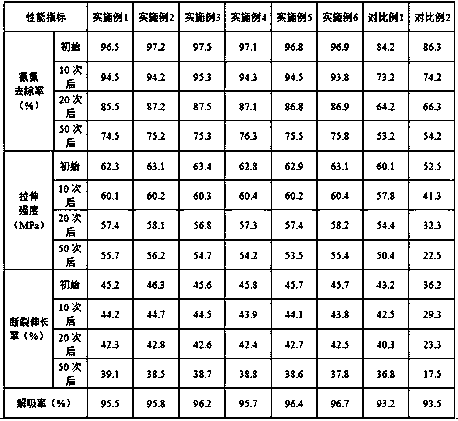

Examples

Embodiment 1

[0033] (1) Grind the biological vermiculite into nano-scale powder, then wash it with deionized water, and then dry it to obtain the biological vermiculite powder; the drying temperature is 118°C, and the drying time is 28 minutes; the average value of the biological vermiculite powder The particle size is 90nm;

[0034] (2) Add sodium alginate into deionized water, heat and mechanically stir until it is translucent without particles, then add the biological vermiculite powder prepared in step (1), continue stirring until uniformly dispersed, and then degas under reduced pressure, Sodium alginate colloid dispersed with biological vermiculite powder was obtained; the heating temperature was 66°C, the speed of mechanical stirring was 380r / min, and the time was 2.5h; the vacuum degree of vacuum defoaming was 12Pa, and the defoaming time was 7min; In the colloid, 4 parts by weight of sodium alginate, 1 part by weight of biological vermiculite powder, and 95 parts by weight of deio...

Embodiment 2

[0037] (1) Grind the biological vermiculite into nano-scale powder, then wash it with deionized water, and then dry it to obtain the biological vermiculite powder; the drying temperature is 110°C, and the drying time is 40 minutes; the average value of the biological vermiculite powder The particle size is 50nm;

[0038](2) Add sodium alginate into deionized water, heat and mechanically stir until it is translucent without particles, then add the biological vermiculite powder prepared in step (1), continue stirring until uniformly dispersed, and then degas under reduced pressure, Sodium alginate colloid dispersed with biological vermiculite powder was obtained; the heating temperature was 60°C, the speed of mechanical stirring was 300r / min, and the time was 3h; Among them, 3 parts by weight of sodium alginate, 1 part by weight of biological vermiculite powder, and 96 parts by weight of deionized water;

[0039] (3) Coat the sodium alginate colloid prepared in step (2) on a sm...

Embodiment 3

[0041] (1) Grind the biological vermiculite into nano-scale powder, then wash it with deionized water, and then dry it to obtain the biological vermiculite powder; the drying temperature is 130°C, and the drying time is 20 minutes; the average value of the biological vermiculite powder The particle size is 200nm;

[0042] (2) Add sodium alginate into deionized water, heat and mechanically stir until it is translucent without particles, then add the biological vermiculite powder prepared in step (1), continue stirring until uniformly dispersed, and then degas under reduced pressure, Sodium alginate colloid dispersed with biological vermiculite powder was prepared; the heating temperature was 70°C, the speed of mechanical stirring was 500r / min, and the time was 2h; the vacuum degree of vacuum defoaming was 20Pa, and the defoaming time was 5min; Among them, 5 parts by weight of sodium alginate, 2 parts by weight of biological vermiculite powder, and 93 parts by weight of deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com