Titanium dioxide ceramic composition, slurry, preparation method and application for 3D direct writing printing

A technology of titanium dioxide and ceramic slurry, which is applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of high-solid content ceramic slurry that have not been reported yet, and achieve reduced drying cracking, large application prospects, and good molding performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Another aspect of the embodiment of the present invention also provides the preparation method of the aforementioned titanium dioxide ceramic slurry for 3D direct writing printing, which includes: uniformly mixing the titanium dioxide ceramic material, dispersant, binder and solvent, and then stirring to obtain the obtained Titanium dioxide ceramic slurry for 3D direct writing printing.

[0044] In some embodiments, the mass ratio of the dispersant, binder, solvent, and titanium dioxide ceramic material is (0.30-1.20): (0.05-2.00): (21.80-39.65): (60.00-75.00).

[0045] In some embodiments, the preparation method specifically includes:

[0046] Dissolve the dispersant and binder in the solvent at room temperature, and stir mechanically for 30-90 minutes to form a uniform mixed solution;

[0047] The titanium dioxide ceramic material is gradually added into the mixed solution, mechanically stirred for 1.0-1.5 hours, and the rotation speed is 1000-2000 rpm / min, and the t...

Embodiment 1

[0070] (1) Preparation of titanium dioxide ceramic slurry

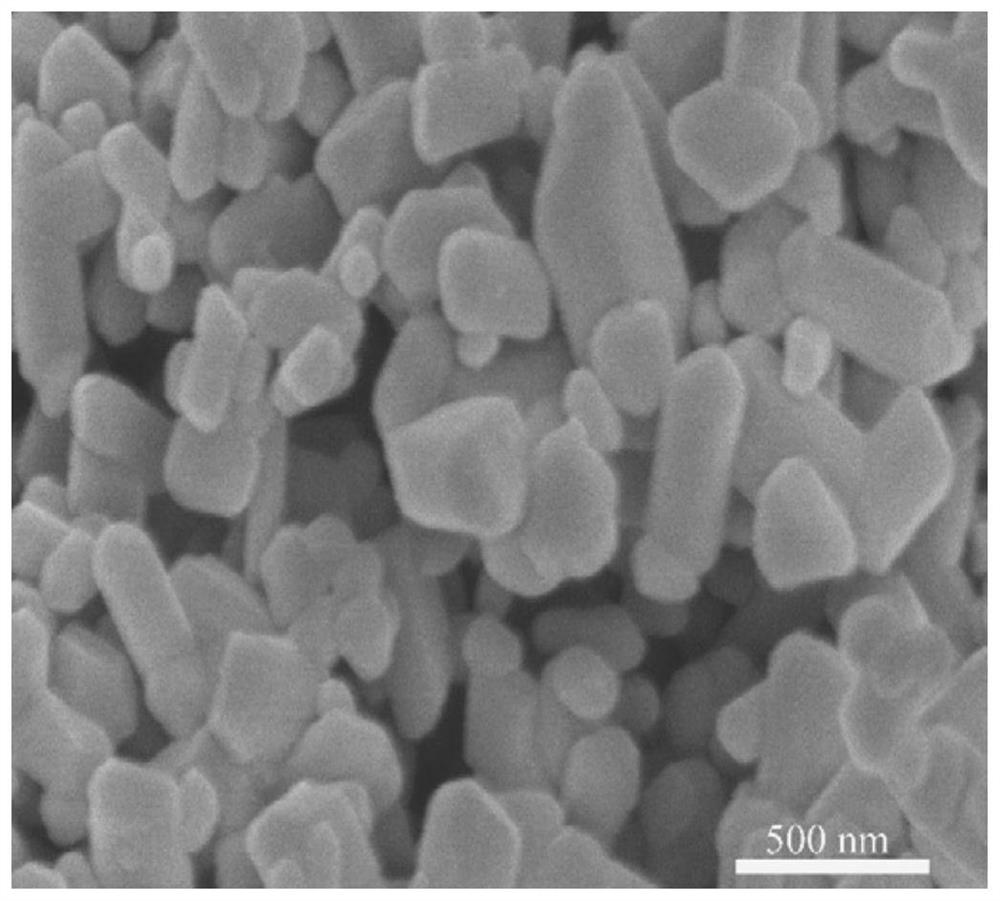

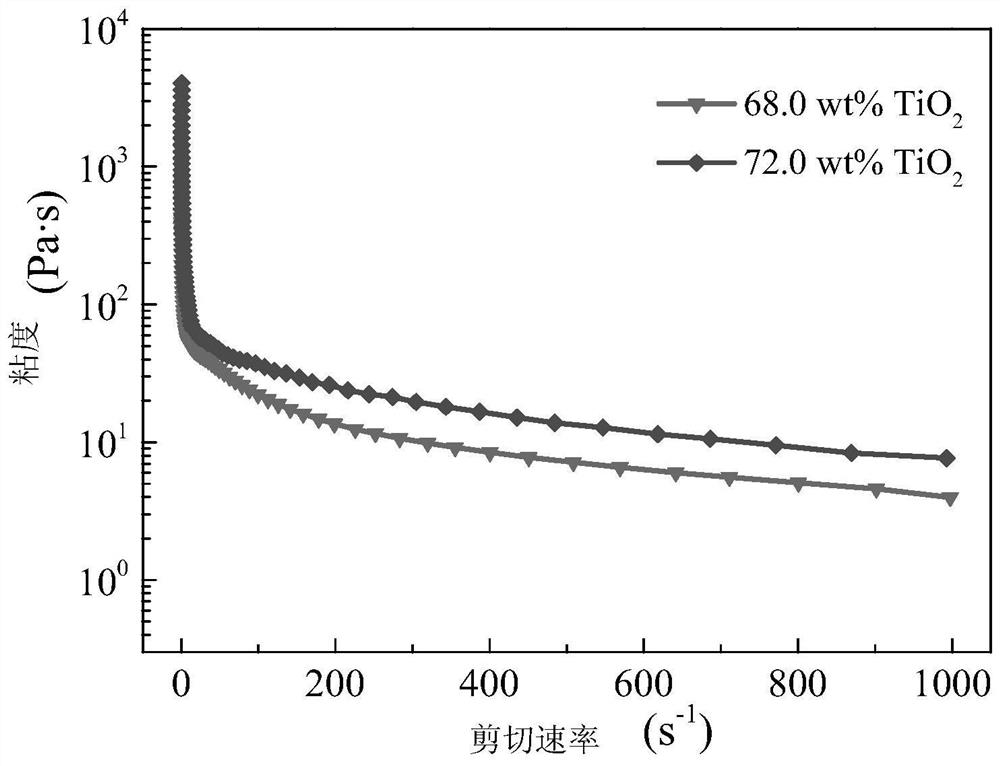

[0071] First, dissolve sodium hexametaphosphate with a mass fraction of 0.30% and sodium alginate with a mass fraction of 0.05% in deionized water with a mass fraction of 31.65% at room temperature, and mechanically stir for 30 minutes to fully dissolve them in deionized water Form a homogeneous solution; then the mass fraction is 68.00% titanium dioxide ceramic powder gradually added in the homogeneous solution (SEM of titanium dioxide ceramic powder such as figure 1 shown), mechanically stirred for 1.0 hour, and the rotating speed was 1500rpm / min, and the titanium dioxide ceramic slurry was prepared; finally, the prepared titanium dioxide ceramic slurry for 3D printing was transferred to the material tube for vibration and defoaming, and stood for 0.5 hours for use. The viscosity of the ceramic slurry is figure 2 shown.

[0072] (2) 3D direct writing printing titanium dioxide ceramic parts

[0073] Correctly ins...

Embodiment 2

[0075] (1) Preparation of titanium dioxide ceramic slurry

[0076] First, dissolve sodium hexametaphosphate with a mass fraction of 0.30% and sodium alginate with a mass fraction of 0.05% in deionized water with a mass fraction of 27.65% at room temperature, and mechanically stir for 60 minutes to fully dissolve them in deionized water Form a uniform solution; then gradually add titanium dioxide ceramic powder with a mass fraction of 72.00% into the uniform solution, and mechanically stir for 1.0 hour at a speed of 1500rpm / min to prepare a titanium dioxide ceramic slurry; finally, the prepared titanium dioxide for 3D printing The ceramic slurry is transferred to the material pipe for shaking and defoaming, and it is left to stand for 0.5 hours for use. The viscosity of the ceramic slurry is as follows: figure 2 shown.

[0077] (2) 3D direct writing printing titanium dioxide ceramic parts

[0078] Correctly install the material tube containing the titanium dioxide ceramic sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com