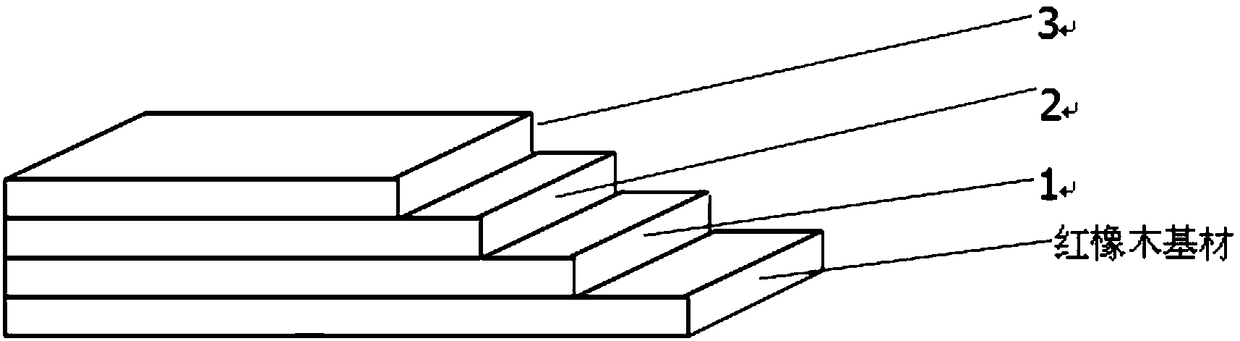

Anti-color-infiltration red oak two-component aqueous woodware coating structure

A two-component, water-based technology, used in antifouling/underwater coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as deterioration, discoloration and adhesion of paint films, and achieve excellent surface effects Strong adhesion and good filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) Two-component water-based wood sealing primer, take the following raw materials by weight: 5 parts of water-based acrylic emulsion AC259875, 1 part of film-forming aid DPM, 3.5 parts of film-forming aid DPNB, 0.3 part of defoamer Tego810, base Material wetting agent Coatosil1211 0.4 parts, pH regulator AMP-95 0.1 parts, preservative CI-15HS 0.2 parts, thickener XS71 1 part, deionized water 18.5 parts, water-based curing agent Aquolin 268 15 parts, deionized water Two twenty servings.

[0060] At a medium dispersion speed of 500-1000rpm, add film-forming aids, defoamers, substrate wetting agents, pH value regulators, preservatives, thickeners, and deionized water into the water-based acrylic emulsion one by one, and disperse After uniformity, the main agent is finished; add water-based curing agent and deionized water before coating construction, stir evenly without particles, filter, and use within 3 hours.

[0061] (2) Two-component water-based wood polishing prim...

Embodiment 2

[0073] (1) Two-component water-based wood sealing primer, weigh the following raw materials by weight: 80 parts of water-based acrylic emulsion AC31, 1 part of film-forming aid DPM, 4 parts of film-forming aid DPNB, 0.3 parts of defoamer BYK025, 0.3 parts of substrate wetting agent 1065, 0.1 parts of pH regulator AMP-95, 0.2 parts of preservative CI-15HS, 1 part of thickener RM-2020, 13.1 parts of deionized water, 13 parts of water-based curing agent OS-9018 , two 20 parts of deionized water.

[0074] At a medium dispersion speed of 500-1000rpm, add film-forming aids, defoamers, substrate wetting agents, pH value regulators, preservatives, thickeners, and deionized water into the water-based acrylic emulsion one by one, and disperse After uniformity, the main agent is finished; add water-based curing agent and deionized water before coating construction, stir evenly without particles, filter, and use within 3 hours.

[0075] (2) Two-component water-based wood polishing primer...

Embodiment 3

[0087] (1) Two-component water-based wood sealing primer, take the following raw materials by weight: 85 parts of water-based acrylic emulsion A2651, 2 parts of film-forming aid DPNB, 0.2 part of defoamer Tego810, 0.2 part of defoamer Tego902W, base Material wetting agent TegoWet KL 245 0.5 parts, pH regulator AMP-95 0.1 parts, preservative CI-15HS 0.2 parts, thickener RM-2020 0.8 parts, deionized water-11 parts, water-based curing agent Aquolin 268 15 parts , two 20 parts of deionized water.

[0088] At a medium dispersion speed of 500-1000rpm, add film-forming aids, defoamers, substrate wetting agents, pH value regulators, preservatives, thickeners, and deionized water into the water-based acrylic emulsion one by one, and disperse After uniformity, the main agent is finished; add water-based curing agent and deionized water before coating construction, stir evenly without particles, filter, and use within 3 hours.

[0089] (2) Two-component water-based wood polishing primer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com