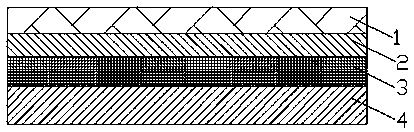

High-gloss thermosensitive paper and a manufacturing process thereof

A manufacturing process and technology of thermal paper, applied in special paper, paper, papermaking, etc., can solve the problems of limited contribution to the gloss of the color-emitting layer, difficulty in achieving high gloss performance, affecting the clarity of thermal printing, etc. Satisfy the printing ink absorption, the thermal printing effect is beautiful, and the effect of ensuring high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A manufacturing process of high-gloss thermal paper, comprising the steps of:

[0035] (1) Choose paper as the coating substrate, and the basis weight is 60g / m 2 , the smoothness of the coating surface is 50-80s;

[0036] (2) Configure the primer coating solution: add water to the primer tank, turn on the stirring device, add dispersant and high-gloss water-washed kaolin, adjust the pH value to 8.0-8.5, and disperse under high-speed conditions (dispersion disc Diameter and rotational speed should ensure that the edge line speed is 23-25m / s) and disperse for 60 minutes, then add hollow balls, water retaining agent, defoamer, styrene-butadiene latex, and continue stirring for 30 minutes under low-speed stirring conditions to form a primer coating liquid ready for use;

[0037] The primer coating solution is composed of the following raw materials in parts by weight: 0.8 parts of dispersant, 55 parts of high-gloss washed kaolin, 30 parts of hollow balls, 1.7 parts of wat...

Embodiment 2

[0044] A manufacturing process of high-gloss thermal paper, comprising the steps of:

[0045] (1) BOPP film is selected as the coating substrate, the surface of the substrate is smooth and matte, the coating surface is matte, the thickness is 70um, and the material density is 0.85g / cm 3 ;

[0046] (2) Configure the primer coating solution: add water to the primer tank, turn on the stirring device, add dispersant and high-gloss water-washed kaolin, adjust the pH value to 8.0-8.5, and disperse under high-speed conditions (dispersion disc Diameter and rotational speed should ensure that the edge line speed is 23-25m / s) and disperse for 60 minutes, then add hollow balls, water retaining agent, defoamer, acrylic latex, and continue stirring for 30 minutes under low-speed stirring conditions to form a primer coating solution stand-by;

[0047] The primer layer is composed of the following raw materials in parts by weight: 0.8 parts of dispersant, 18.7 parts of high-gloss washed ka...

Embodiment 3

[0054] A manufacturing process of high-gloss thermal paper, comprising the steps of:

[0055] (1) Use PET film as the coating substrate, the thickness of the material is 70um, and the density is 0.95g / cm3;

[0056] (2) Configure the primer coating solution: add water to the primer tank, turn on the stirring device, add dispersant and high-gloss water-washed kaolin, adjust the pH value to 8.0-8.5, and disperse under high-speed conditions (dispersion disc Diameter and rotational speed should ensure that the edge line speed is 23-25m / s) and disperse for 60 minutes, then add hollow balls, water retaining agent, defoamer, acrylic latex, and continue stirring for 30 minutes under low-speed stirring conditions to form a primer coating solution stand-by;

[0057] The primer layer is composed of the following raw materials in parts by weight: 0.8 parts of dispersant, 16.7 parts of high-gloss washed kaolin, 55 parts of hollow balls, 2 parts of water-retaining agent, 0.5 parts of defoam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com