Polyamide reverse osmosis (RO) membrane modified through bulk doping of CNO, and preparation method and application thereof

A technology of reverse osmosis membrane and polyamide, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of decreased rejection rate, poor chlorine resistance, shortened membrane service life, etc., and achieve flux improvement, Membrane performance is stable and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

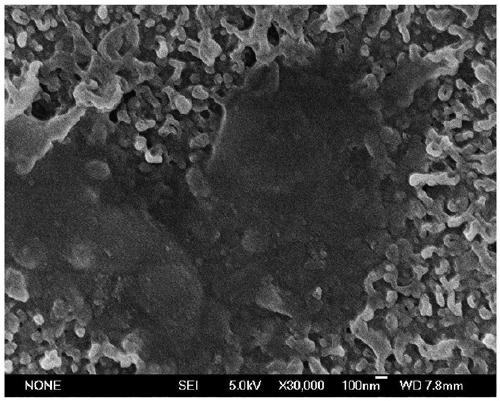

[0030] (1) Clean the polysulfone (PS) ultrafiltration membrane (molecular weight cut-off 30000) with pure water and use it as a support layer for subsequent use;

[0031] (2) Configure an aqueous m-phenylenediamine (MPD) solution with a mass fraction of 2.0%; disperse 0.005 g / L of CNO in the MPD solution by ultrasonication for one hour to obtain a CNO-MPD aqueous phase solution;

[0032] (3) Configuration of the oil phase solution: the configuration mass fraction is 0.1% trimesoyl chloride (TMC) n-hexane solution;

[0033] (4) Preparation of CNO-modified polyamide reverse osmosis membrane: Take out the PS membrane and fix it on a glass plate, dry the water with an air knife, pour the CNO-MPD aqueous phase solution on the surface of the PS membrane, and pour off the excess after 5 minutes The water phase solution was blown dry with an air knife, and then the oil phase solution was poured on the membrane surface, reacted for 1 minute, and poured off the excess oil phase solution...

Embodiment 2

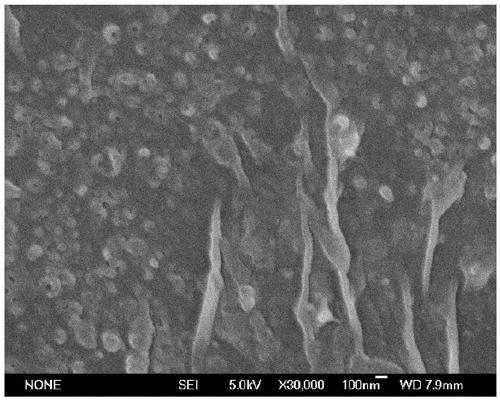

[0043] (1) Clean the polysulfone (PS) ultrafiltration membrane (molecular weight cut-off 30000) with pure water and use it as a support layer for subsequent use;

[0044] (2) Configure a m-phenylenediamine (MPD) aqueous solution with a mass fraction of 2.0%; disperse 0.01 g / L of CNO in the MPD solution by ultrasonication for one hour to obtain a CNO-MPD aqueous phase solution;

[0045] (3) Configuration of the oil phase solution: the configuration mass fraction is 0.1% trimesoyl chloride (TMC) n-hexane solution;

[0046] (4) Preparation of CNO-modified polyamide reverse osmosis membrane: Take out the PS membrane and fix it on a glass plate, dry the water with an air knife, pour the CNO-MPD aqueous phase solution on the surface of the PS membrane, and pour off the excess after 5 minutes The water phase solution was blown dry with an air knife, and then the oil phase solution was poured on the membrane surface, reacted for 1 minute, and poured off the excess oil phase solution. ...

Embodiment 3

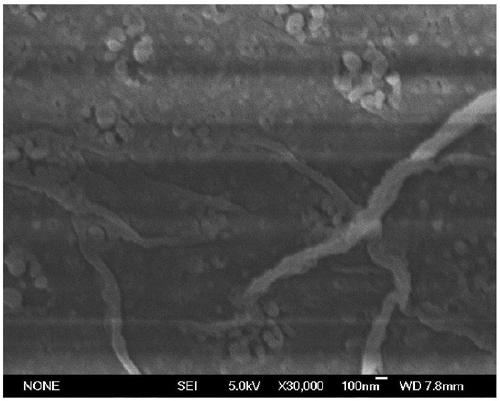

[0056] (1) Clean the polysulfone (PS) ultrafiltration membrane (molecular weight cut-off 30000) with pure water and use it as a support layer for subsequent use;

[0057] (2) Configure a m-phenylenediamine (MPD) aqueous solution with a mass fraction of 2.0%; disperse 0.02 g / L of CNO in the MPD solution by ultrasonication for one hour to obtain a CNO-MPD aqueous phase solution;

[0058] (3) Configuration of the oil phase solution: the configuration mass fraction is 0.1% trimesoyl chloride (TMC) n-hexane solution;

[0059] (4) Preparation of CNO-modified polyamide reverse osmosis membrane: Take out the PS membrane and fix it on a glass plate, dry the water with an air knife, pour the CNO-MPD aqueous phase solution on the surface of the PS membrane, and pour off the excess after 5 minutes The water phase solution was blown dry with an air knife, and then the oil phase solution was poured on the membrane surface, reacted for 1 minute, and poured off the excess oil phase solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com