A kind of waste water treatment device and treatment method for livestock and poultry breeding based on forward osmosis membrane

A forward osmosis membrane, livestock and poultry breeding technology, applied in the fields of animal husbandry wastewater treatment, biological treatment devices, water/sewage treatment, etc. The effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

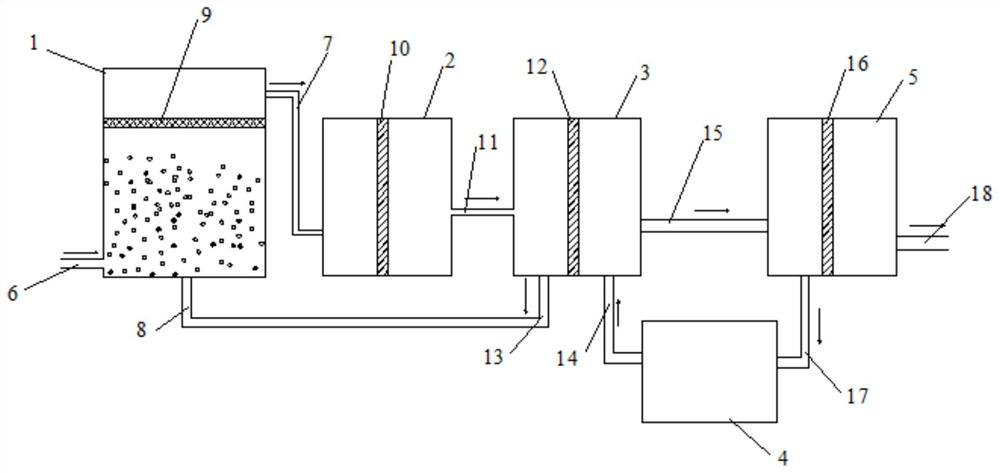

[0039] A kind of wastewater treatment device for livestock and poultry breeding based on forward osmosis membrane, specifically as figure 1 As shown, it includes a biological reaction tank 1, a filter tank 2, a forward osmosis device 3, a draw liquid tank 4, and a reverse osmosis device 5; the lower end of one side of the biological reaction tank 1 is provided with a water inlet pipe 6, and the livestock and poultry breeding wastewater passes through the water inlet pipe 6 Enter the bioreactor 1 for processing;

[0040]The upper end of the opposite side is provided with a first outlet pipe 7, and the bottom end is provided with a first liquid inlet pipe 8; the biological reaction tank 1 is filled with activated sludge, particle diameter of volcanic stone powder and willow bark powder of 1-3mm mixture, and the mass ratio of volcanic stone powder, willow bark powder and aerobic activated sludge is 1:5:100. The large number of pores in volcanic stone powder can provide places for...

Embodiment 2

[0054] Utilize the method for processing the wastewater for livestock and poultry breeding based on the wastewater treatment device for livestock and poultry breeding of embodiment 1 based on forward osmosis membrane, comprising the following steps:

[0055] Step 1, COD concentration is 3568mg / L, and TN concentration is 543mg / L, and the livestock and poultry breeding waste water that TP concentration is 96mg / L is passed into bioreactor 1, and COD volumetric load is set to be 5.0kgCOD / ( in bioreactor 1 m 3 d), the DO concentration is 3mg / L, the HRT is 8h, and the effluent of the biological reaction tank 1 is obtained after the reaction is completed;

[0056] Step 2, passing the effluent of the biological reaction tank 1 into the filter tank 2, and after being filtered by the micro-filter 10 in the filter tank 2, the effluent of the filter tank 2 is obtained;

[0057] Step 3, pass the effluent from the filter tank 2 into the left side of the forward osmosis device 3, and simult...

Embodiment 3

[0061] Utilize the method for processing the wastewater for livestock and poultry breeding based on the wastewater treatment device for livestock and poultry breeding of embodiment 1 based on forward osmosis membrane, comprising the following steps:

[0062] Step 1, COD concentration is 1986mg / L, and TN concentration is 437mg / L, and the livestock and poultry waste water that TP concentration is 83mg / L is placed in bioreaction tank 1, and the COD volume load in setting bioreaction tank 1 is 6.0kgCOD / (m 3 d), the DO concentration is 4mg / L, the HRT is 9h, and the effluent of the biological reaction tank 1 is obtained after the reaction is completed;

[0063] Step 2, passing the effluent of the biological reaction tank 1 into the filter tank 2, and after being filtered by the micro-filter 10 in the filter tank 2, the effluent of the filter tank 2 is obtained;

[0064] Step 3, pass the effluent from the filter tank 2 into the left side of the forward osmosis device 3, and simultane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com