Methanol-to-olefins reaction product gas and catalyst separation system and separation process

A methanol-to-olefin and separation system technology, which is used in the purification/separation of hydrocarbons, organic chemistry, hydrocarbons, etc., can solve the problem of scaling on the inner wall of methanol-reaction gas heat exchangers, reduction of heat exchange efficiency and system separation efficiency, The three-stage cyclone separator has poor separation effect, etc., to avoid the removal of catalyst solids, high porosity, and elimination of secondary water pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] The present invention aims at the characteristics of the reaction product gas in the methanol-to-olefins industrial device, and optimizes the system process. After removing fine catalyst powder, it enters the oxide washing tower for further cooling, recovers oxygenated compounds, and then enters the olefin separation unit.

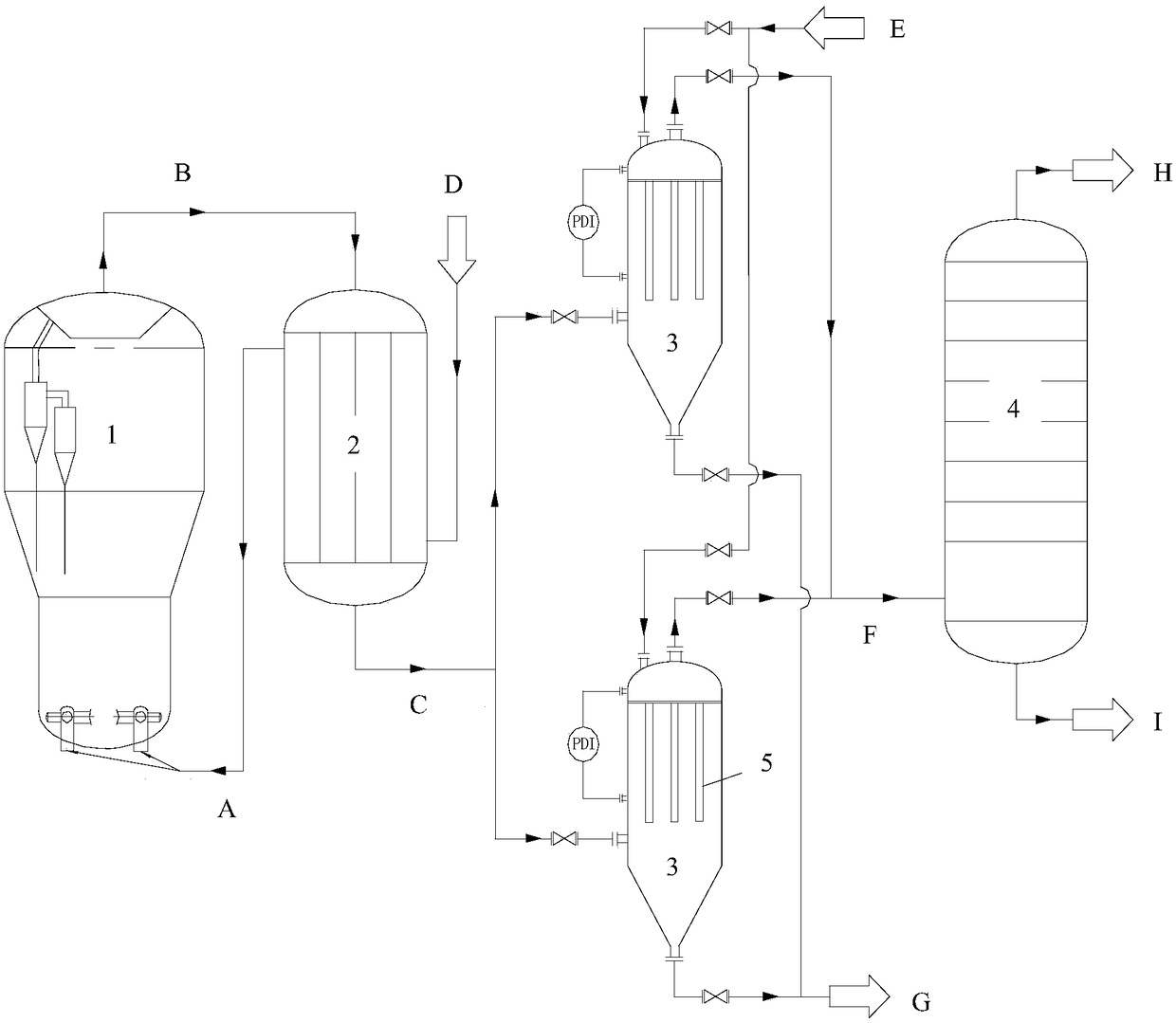

[0026] see figure 1 , the combined process of methanol to olefins reaction product gas and catalyst separation provided by the present invention, the process equipment includes methanol to olefins reactor 1, methanol-reaction gas heat exchanger 2, high temperature catalyst removal equipment 3, oxide scrubber 4 And filter element 5 (using high temperature membrane elements).

[0027]The methanol-to-olefins reactor 1 adopts a turbulent bed reactor (including a dense-phase zone and a dilute-phase zone), the reaction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap