A kind of composite antibacterial polyurethane block polymer and its preparation and application

A polyurethane block and composite antibacterial technology, which is applied in the field of composite antibacterial polyurethane block polymers and its preparation and application, can solve the problems of poor antibacterial properties, and achieve the effect of improving antibacterial properties and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

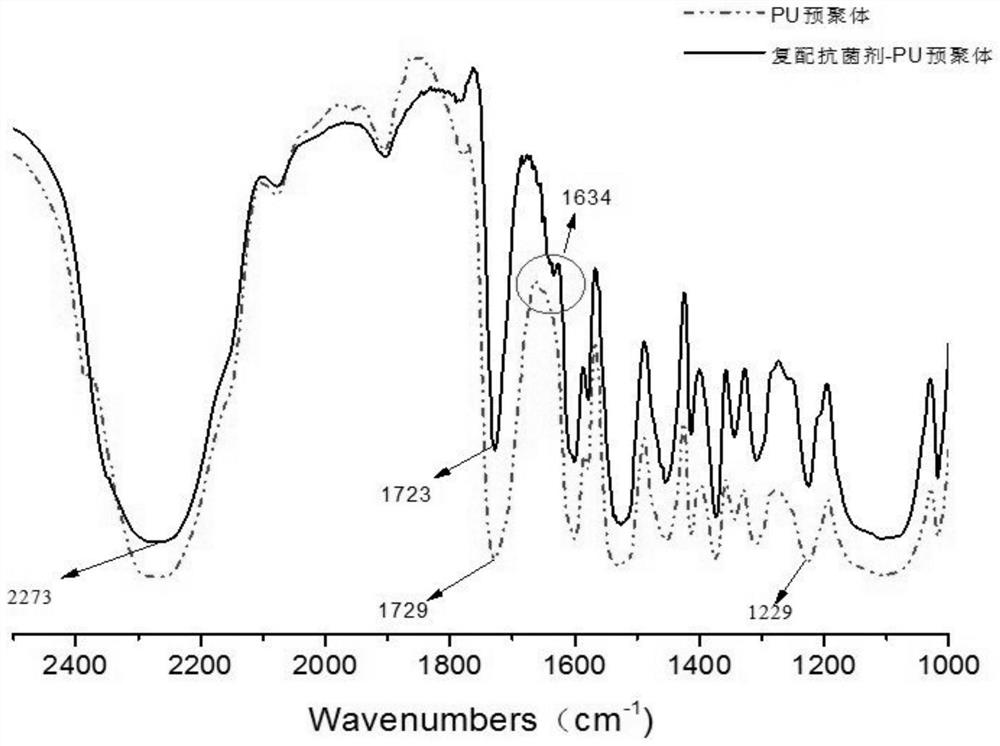

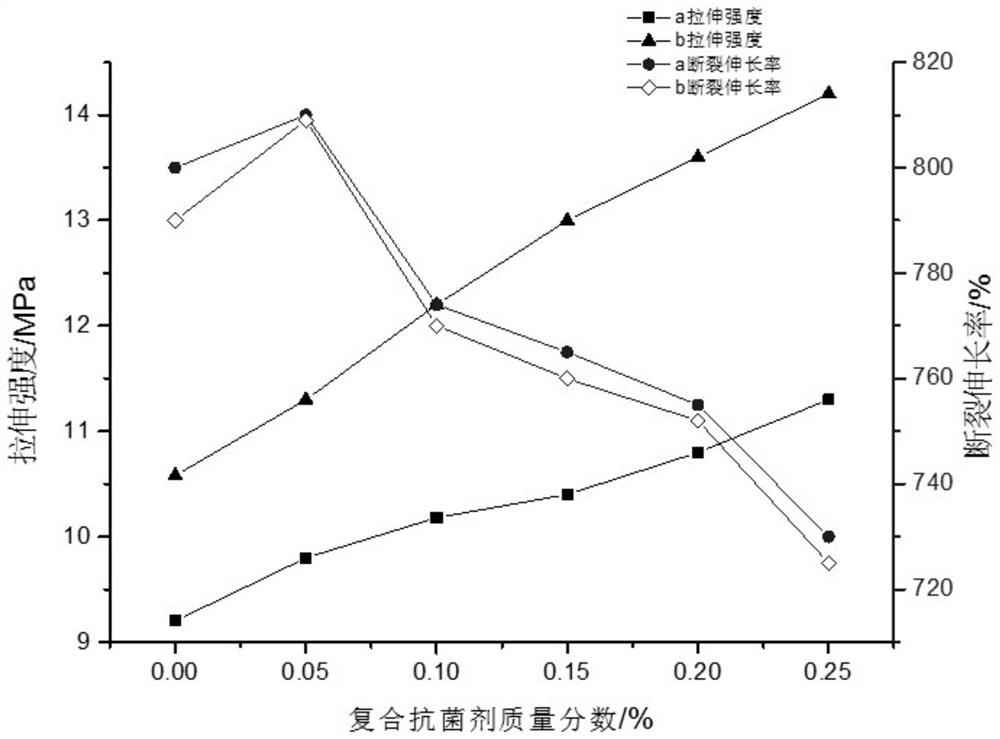

[0031]Add 20 parts by weight of PEG-2000 and 4 parts by weight of PPG-3050D into the reaction bottle, heat to 120°C and vacuum dry for 2 hours to cool down to room temperature, add 17 parts by weight of MDI-50, 1.5 parts by weight of composite reactive antibacterial agent, and heat up to 80 ℃ reaction, use di-n-butylamine acetone method to titrate the isocyanate content, reach the predetermined value, stop the reaction, and obtain A component. The dihydroxy quaternary ammonium salt: polyhexamethylene guanidine salt in the compound reaction antibacterial agent is 1:5 (mass ratio).

[0032] Add 100 parts by weight of PPG-2000D, 20 parts by weight of PPG-3050D and 0.48 parts by weight of catalyst into the reaction bottle, dry it in vacuum at 120°C for 2 hours, cool down to room temperature, add 6 parts by weight of E-300, heat to 90°C-100°C, and vacuum Dry for 1 hour, lower to room temperature, add 0.25 parts by weight of dehydrated s-triazine to prepare component B.

[0033] Th...

Embodiment 2

[0035] Add 40 parts by weight of PPG-4000D and 10 parts by weight of PPG-3050D into the reaction bottle, heat to 120°C and vacuum dry for 2 hours and cool down to room temperature. ℃ reaction, use di-n-butylamine acetone method to titrate the isocyanate content, reach the predetermined value, stop the reaction, and obtain A component. The dihydroxy quaternary ammonium salt: polyhexamethylene guanidine salt in the compound reaction antibacterial agent is 1:3 (mass ratio).

[0036] Add 60 parts by weight of PPG-2000D, 30 parts by weight of PPG-3050D and 0.36 parts by weight of catalyst into the reaction bottle, dry it in vacuum at 120°C for 2 hours, cool down to room temperature, add 8 parts by weight of E-300, heat to 90°C-100°C, and vacuum Dry for 1 hour, cool down to room temperature, and add 0.19 parts by weight of dehydrated s-triazine to prepare component B.

[0037] The ratio of isocyanate group to active hydrogen is 1.05, A and B are mixed, stirred and degassed, and cur...

Embodiment 3

[0039] Add 20 parts by weight of PPG-1000D and 8 parts by weight of PPG-3050D into the reaction bottle, heat to 120°C and vacuum-dry for 2 hours to cool down to room temperature, add 20 parts by weight of MDI-50, 2.5 parts by weight of composite reactive antimicrobial agent, and heat up to 80°C For the reaction, titrate the isocyanate content with the di-n-butylamine acetone method to reach a predetermined value, stop the reaction, and obtain component A. The dihydroxy quaternary ammonium salt: polyhexamethylene guanidine salt in the composite reaction antibacterial agent is 1:1 (mass ratio).

[0040] Add 80 parts by weight of PPG-2000D, 40 parts by weight of PPG-3050D and 0.48 parts by weight of catalyst into the reaction flask, dry it in vacuum at 120°C for 2 hours, cool down to room temperature, add 8 parts by weight of E-300, 2 parts by weight of E-100, and heat to 90°C-100°C, vacuum-dried for 1 hour, lowered to room temperature, and added 0.26 parts by weight of dehydrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com