PDMS-PTFE film for improving performance of nano friction power generator and preparation method thereof

A PDMS-PTFE, nano-friction technology, applied in the field of tribo-nano power generation, can solve the problems of different application fields and inability to make transparent films, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

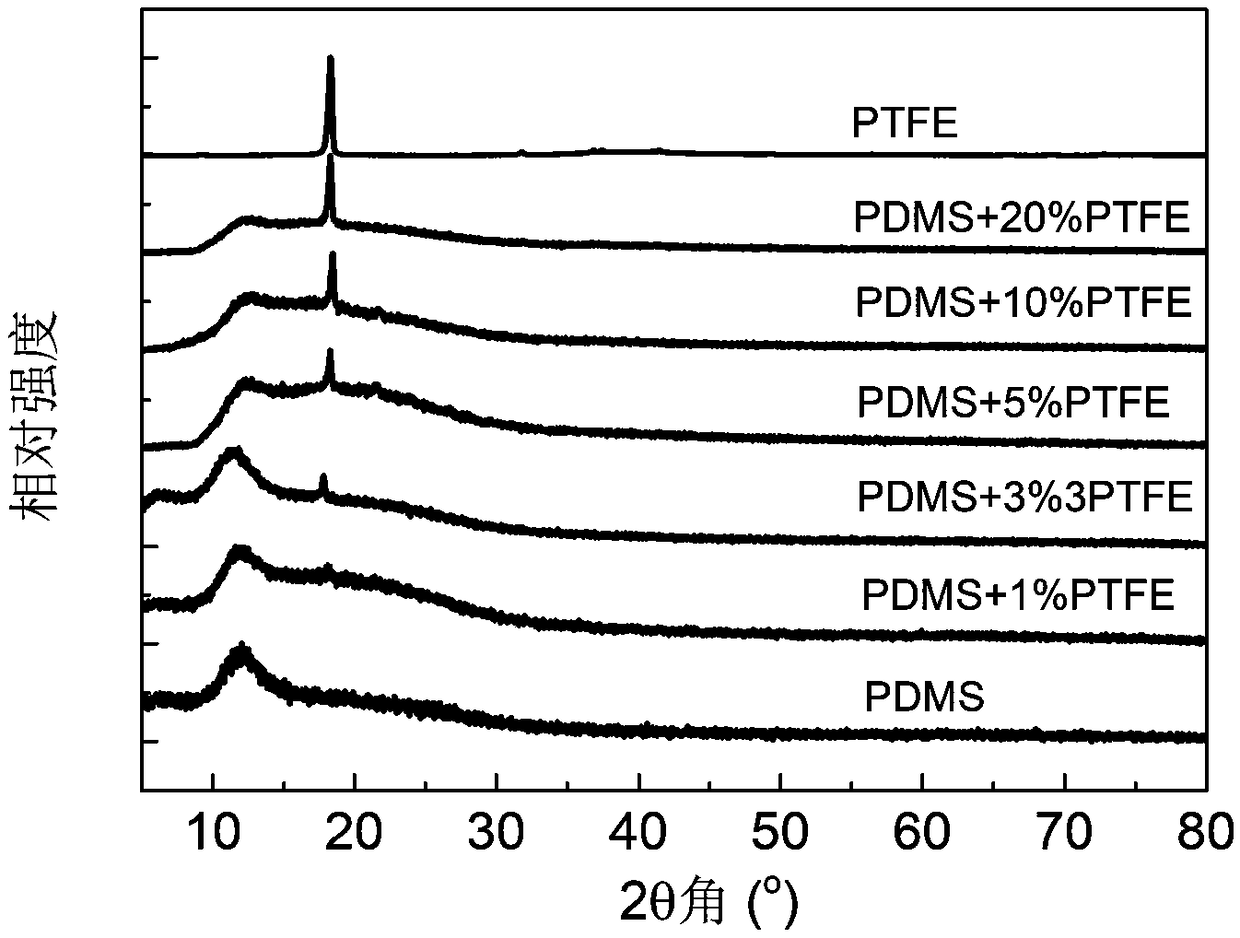

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 10g polydimethylsiloxane prepolymer and dissolve it in 0.1g n-hexane, mix and stir for 10min, so that the two are fully mixed evenly;

[0039] (2) Add PTFE emulsion (the net content of PTFE is 0.1g) to the mixed solution, and heat to 100°C and stir for 0.5h to prepare a mixed solution;

[0040] (3) Cool the above mixed solution to room temperature, add 0.8g tetraethyl orthosilicate cross-linking agent, then add 0.3g dibutyltin dilaurate catalyst, stir at room temperature for 0.5h to prepare uniformly mixed PDMS solution to be solidified; and carry out Degassing treatment to prepare a uniform and bubble-free PDMS solution to be cured;

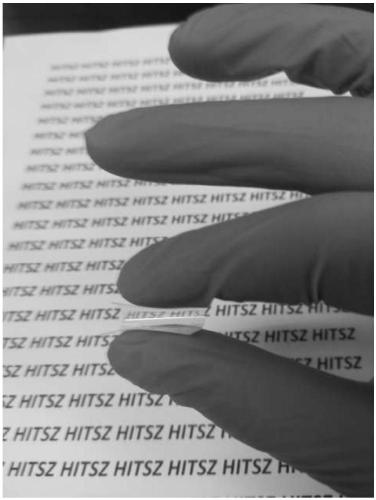

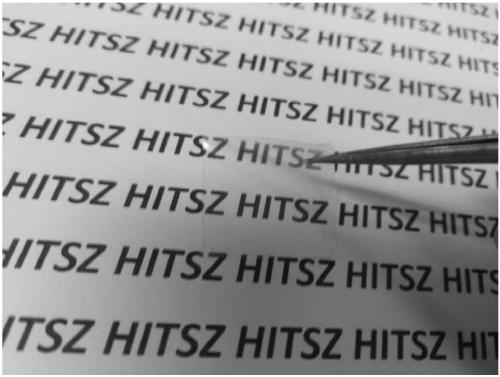

[0041] (4) The above solution was coated on the substrate glass of the nanogenerator, and cured at 40° C. for 8 hours, and the film was peeled off from the substrate to prepare a PDMS-PTFE film.

Embodiment 2

[0043] (1) Weigh 10g of polydimethylsiloxane prepolymer and dissolve it in 1g of n-hexane, mix and stir for 5min, so that the two are fully mixed evenly;

[0044] (2) Add PTFE emulsion (wherein the net content of PTFE is 0.3g) to the mixed solution, and stir for 5 hours in a hot environment at 60°C to prepare a mixed solution;

[0045] (3) Cool the above mixed solution to room temperature, add 0.9g tetraethyl orthosilicate crosslinking agent, then add 0.3g dibutyltin dilaurate catalyst, stir at room temperature for 0.5h to obtain a uniformly mixed PDMS solution to be solidified, and carry out Degassing treatment to prepare a uniform and bubble-free PDMS solution to be cured;

[0046] (4) Coating the above-mentioned solution on the substrate silicon wafer of the nanogenerator, and curing at 60° C. for 6 hours, peeling off the film from the substrate to prepare a PDMS-PTFE film.

Embodiment 3

[0048] (1) By weight, take 10g of polydimethylsiloxane prepolymer and dissolve it in 1g of n-hexane, mix and stir for 5min, so that the two are fully mixed evenly;

[0049] (2) Add PTFE emulsion (wherein the net content of PTFE is 0.5g) to the mixed solution, and stir in a hot environment of 70°C for 3.5h to prepare a mixed solution;

[0050] (3) Cool the above mixed solution to room temperature, add 1g of tetraethyl orthosilicate crosslinking agent, then add 0.2g of dibutyltin dilaurate catalyst, stir at room temperature for 1h to obtain a uniformly mixed PDMS solution to be solidified, and remove it Gas treatment to obtain a uniform and bubble-free PDMS solution to be cured;

[0051] (4) The above solution was coated on the substrate PET plate of the nanogenerator, and cured at 120° C. for 20 minutes, and the film was peeled off from the substrate to obtain a PDMS-PTFE film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com