Silicon carbide nanowire hydrophobic coating and preparation method thereof

A technology of silicon carbide nanowires and hydrophobic coatings, applied in chemical instruments and methods, coatings, carbon compounds, etc., can solve problems such as complex preparation methods, easy cracking, and thick coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) The substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 minutes in sequence to remove dust on the surface, and then dried with nitrogen gas for later use;

[0018] (2) Grind 1.2 g of polycarbosilane into powder, heat it in an oven at 100°C for 3 hours, and dry it for later use;

[0019] (3) Place the polycarbosilane in (2) evenly in the ceramic crucible, place the ceramic crucible in the high temperature zone of the tube furnace, place the substrate in the tail of the tube furnace; vacuumize the tube furnace, and pass Argon, to ensure the normal pressure in the tube furnace, then raise the tube furnace to 1200 °C at 10 °C / min, keep it for 2 hours, then cool to room temperature with the furnace, open the tube furnace to prepare silicon carbide nanowires on the substrate Hydrophobic coating.

Embodiment 2

[0021] (1) The substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 minutes in sequence to remove dust on the surface, and then dried with nitrogen gas for later use;

[0022] (2) Grind 0.8 g of polycarbosilane into powder, heat in an oven at 100°C for 3 hours, and dry for later use;

[0023] (3) Place the polycarbosilane in (2) evenly in the ceramic crucible, place the ceramic crucible in the high temperature zone of the tube furnace, place the substrate in the tail of the tube furnace; vacuumize the tube furnace, and pass Argon, to ensure the normal pressure in the tube furnace, then raise the tube furnace to 1100 °C at 5 °C / min, keep it for 2.5 hours, then cool to room temperature with the furnace, open the tube furnace to prepare silicon carbide nano Wire hydrophobic coating.

Embodiment 3

[0025] (1) The substrate was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 minutes in sequence to remove dust on the surface, and then dried with nitrogen gas for later use;

[0026] (2) Grind 1.0 g of polycarbosilane into powder, heat it in an oven at 100°C for 3 hours, and dry it for later use;

[0027] (3) Place the polycarbosilane in (2) evenly in the ceramic crucible, place the ceramic crucible in the high temperature zone of the tube furnace, place the substrate in the tail of the tube furnace; vacuumize the tube furnace, and pass Argon, to ensure the normal pressure in the tube furnace, then raise the tube furnace at 8 °C / min to 1150 °C, keep it for 3 hours, then cool to room temperature with the furnace, open the tube furnace to prepare silicon carbide nanowires on the substrate Hydrophobic coating.

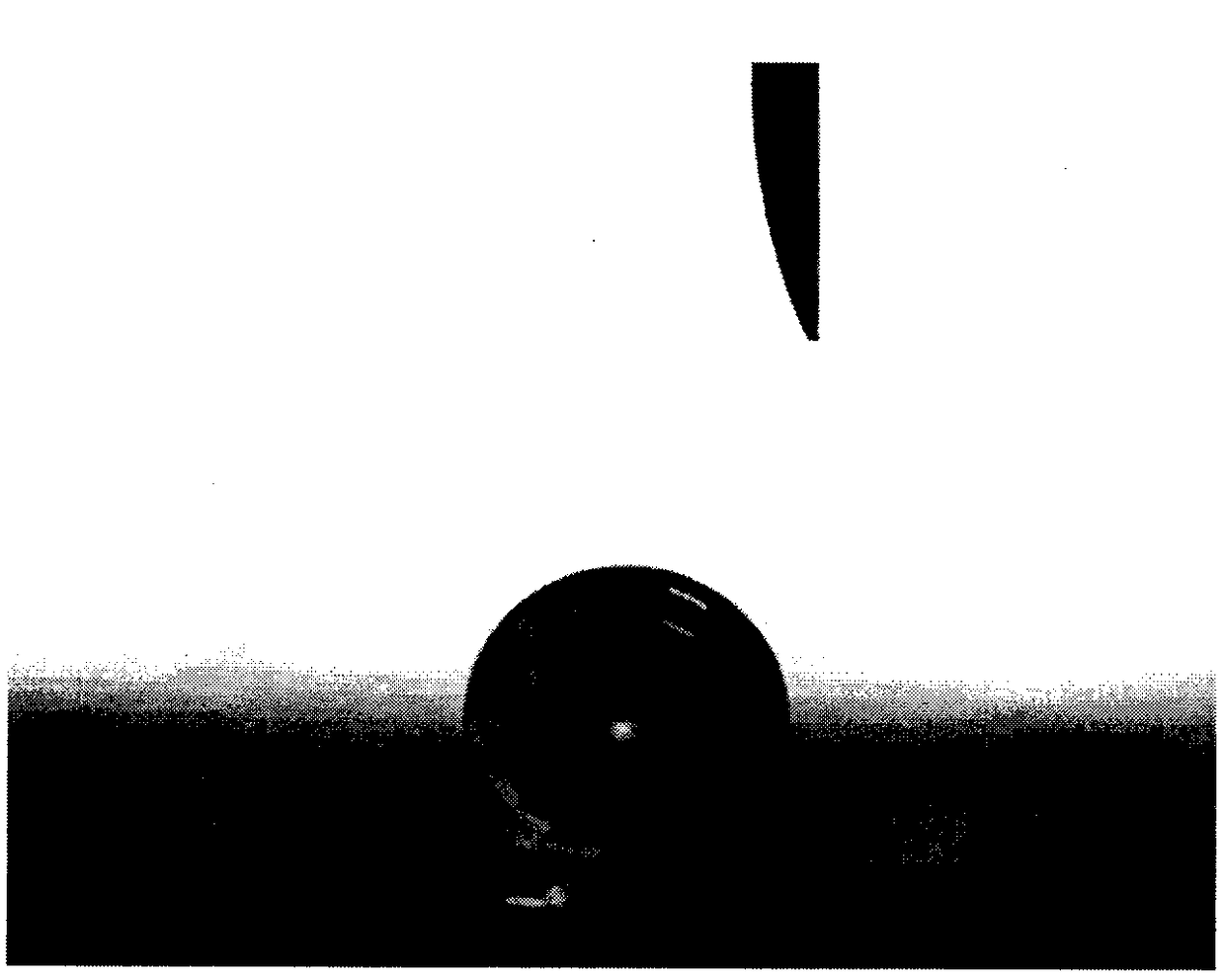

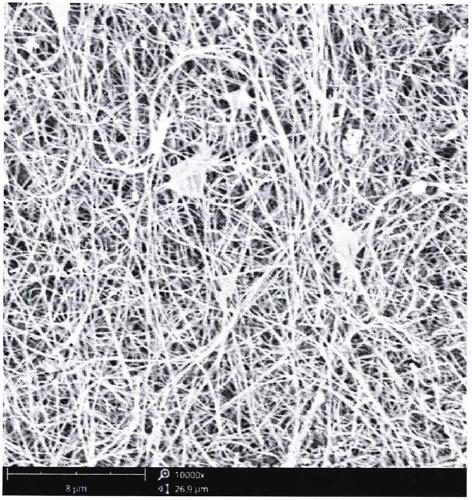

[0028] The silicon carbide nanowire hydrophobic coating that embodiment 1 obtains is characterized, and test result is as follows Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com