Anti-corrosion coating for lampblack pipeline

A technology for anti-corrosion coatings and oil fume pipes, applied in the field of coatings, can solve the problems of decreased life, increased instability, corrosion and erosion, etc., and achieves the effects of good protection, good corrosion resistance and strong spreadability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of anticorrosion paint for oil fume pipe, made of the following substances by weight:

[0024] 40 parts of acrylic resin, 6 parts of epoxy resin, 4 parts of C9 petroleum resin, 28 parts of n-pentanol, 9 parts of nonylphenol polyoxyethylene ether, 12 parts of methyl etherified hexamethylolmelamine resin, 5 parts of functional additives, 0.2 part of wetting agent, 0.5 part of defoamer, 0.3 part of leveling agent, 0.3 part of antioxidant.

[0025] Further, the preparation method of the functional additive comprises the following steps:

[0026] (1) Put starch and water into the reactor according to the weight ratio of 1:7, heat to keep the temperature in the reactor at 79°C, stir at high speed for 30 minutes, and then drop the total mass of 5 % phosphoric acid solution, after high-speed stirring for 1 hour, take it out and pour it into ethanol for precipitation, then rinse it once with deionized water, then vacuum filter and dry it to get the reactant A for use;

...

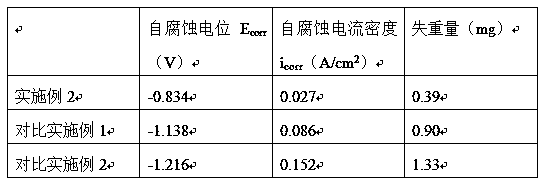

Embodiment 2

[0036] A kind of anticorrosion paint for oil fume pipe, made of the following substances by weight:

[0037] 42 parts of acrylic resin, 8 parts of epoxy resin, 6 parts of C9 petroleum resin, 30 parts of n-pentanol, 11 parts of nonylphenol polyoxyethylene ether, 14 parts of methyl etherified hexamethylolmelamine resin, 7 parts of functional additives, 0.4 part of wetting agent, 1 part of defoamer, 0.5 part of leveling agent, 0.4 part of antioxidant.

[0038] Further, the preparation method of the functional additive comprises the following steps:

[0039] (1) Put starch and water into the reactor according to the weight ratio of 1:8, heat to keep the temperature in the reactor at 80°C, stir at high speed for 33 minutes, and then drop the total mass of 5 % phosphoric acid solution, after high-speed stirring for 1.3h, take it out and pour it into ethanol for precipitation, then rinse it once with deionized water, then vacuum filter and dry it to get reactant A for subsequent use...

Embodiment 3

[0049] A kind of anticorrosion paint for oil fume pipe, made of the following substances by weight:

[0050] 44 parts of acrylic resin, 9 parts of epoxy resin, 7 parts of C9 petroleum resin, 32 parts of n-amyl alcohol, 12 parts of nonylphenol polyoxyethylene ether, 16 parts of methyl etherified hexamethylol melamine resin, 8 parts of functional additives, 0.5 parts of wetting agent, 1.5 parts of defoamer, 0.6 parts of leveling agent, 0.6 parts of antioxidant.

[0051] Further, the preparation method of the functional additive comprises the following steps:

[0052](1) Put starch and water into the reactor according to the weight ratio of 1:9, heat to keep the temperature in the reactor at 83°C, stir at high speed for 35 minutes, and then drop the total mass of 5 % phosphoric acid solution, after high-speed stirring for 1.5h, take it out and pour it into ethanol for precipitation, then rinse it once with deionized water, then vacuum filter and dry it to get reactant A for subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com