Hemp seed oil and production method thereof

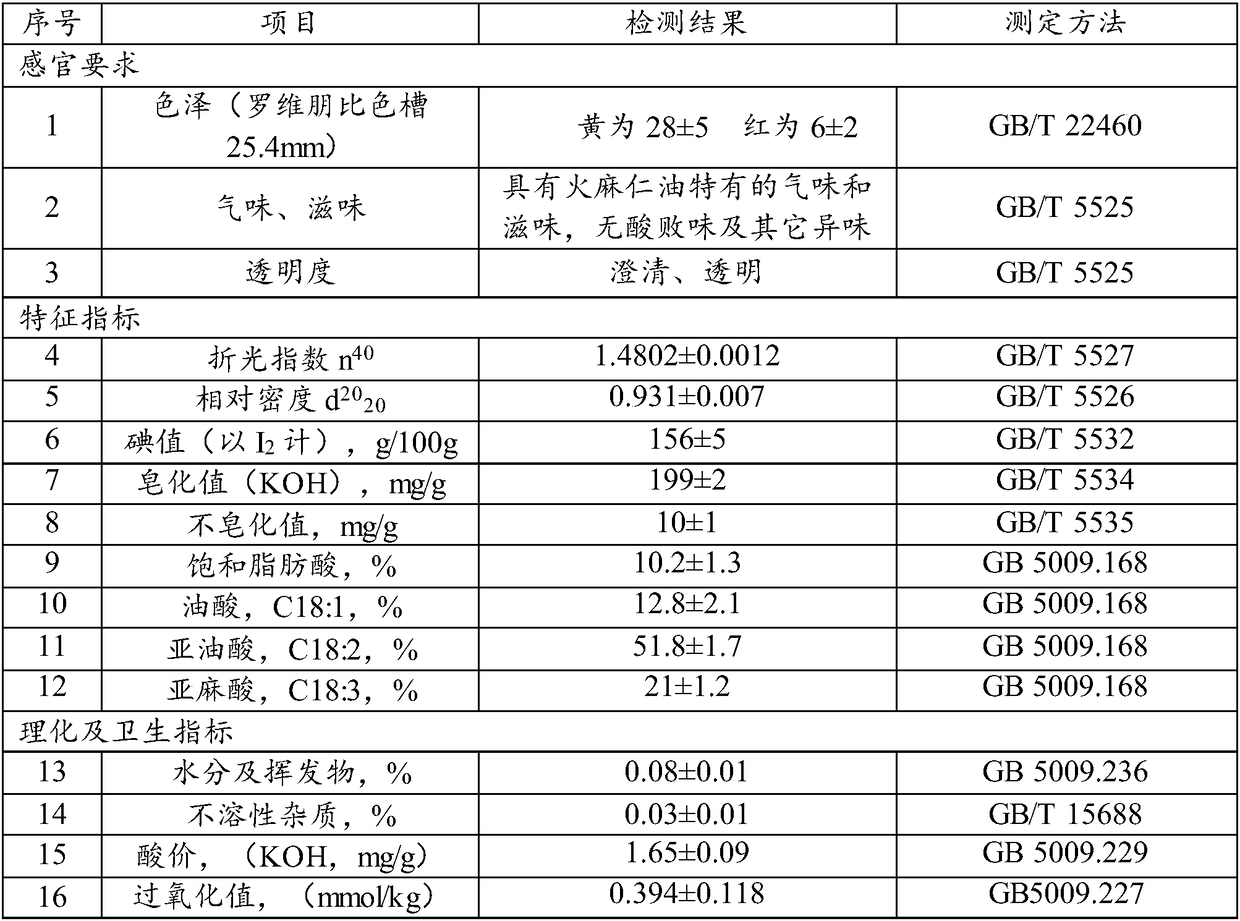

A technology of hemp seed oil and hemp seed, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems that affect the wide application and in-depth development of hemp seed oil, and the quality of hemp seed oil is not high , can not be removed and other problems, to achieve the effect of improving stability, reducing acid value and peroxide value, and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation method of hemp seed oil of the present invention

[0024] After preliminary screening of raw materials, hemp seeds with high oil content and high quality produced in Bama, Guangxi were selected. After screening and cleaning impurities, hemp seeds were shelled by laser cutting and extrusion shelling. The laser cutting power was 50W. The cutting speed is 25mm / s, and the hemp seeds are cut to a cutting width of 2.5mm to obtain the hemp seeds without the nut coat, which are pulverized by a liquid nitrogen low-temperature pulverizer. Put 1 kg of hemp seed crushed raw material into the filter bag, put it into a small hydraulic press, the temperature is 45 °C, the pressing pressure is 55 MPa, and the pressing is repeated 4 times. Hemp seed virgin oil is placed at 4°C for winterization for 36 hours, colloids and glycerides with higher freezing points in the sediment oil, and then filtered through a filter element of 1.0um, and the oil filter is pre...

Embodiment 2

[0027] Embodiment 2: the preparation method of hemp seed oil of the present invention

[0028] Select hemp seeds with high oil content and high quality from Bama, Guangxi. After screening and removing impurities, laser cutting and extrusion shelling are used to shell the hemp seeds. The power of the laser cutting is 40W, and the cutting speed is 15mm / s , cut until the cutting width of the hemp seeds is 3.5mm, and obtain the hemp seeds without the nut coat, which are pulverized through a liquid nitrogen low-temperature pulverizer. 8kg hemp seed pulverized raw material is packed in the filter bag, puts into large-scale hydraulic press machine, temperature is 55 ℃, and pressing pressure is 80MPa, repeatedly presses 3 times, and the oil yield of pressing is 80.1%. Hemp seed virgin oil is placed at 4°C for winterization for 48 hours, colloids and glycerides with higher freezing points in the sediment oil, and then filtered through a filter element of 0.5um, and the oil filter is pr...

Embodiment 3

[0031] Embodiment 3: the preparation method of hemp seed oil of the present invention

[0032] Select hemp seeds with high oil content and high quality produced in Bama, Guangxi. After screening and cleaning impurities, laser cutting and extrusion shelling are used to shell the hemp seeds. The laser cutting power is 50W, and the cutting speed is 25mm / s , cut until the cutting width of the hemp seeds is 1.8 mm, and obtain the hemp seeds without the nut coat, which are pulverized by a liquid nitrogen low-temperature pulverizer. 12kg hemp seed pulverized raw material is packed in the filter bag, puts into large-scale hydraulic press, temperature is 30 ℃, and squeezing pressure is 55MPa, repeatedly squeezes 3 times, and squeezing oil yield is 75.2%. Hemp seed virgin oil is placed at 0°C for winterization for 48 hours, and colloids and glycerides with higher freezing points in the sediment oil are then filtered through a filter element of 0.8um and pressurized to 0.20Mpa to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com