An aluminum alloy strip for continuous deep drawing processing of small metal stamping parts and its preparation method

A technology for aluminum alloy strips and stamping parts, which is applied in the field of aluminum alloy strips and its preparation, can solve the problems of unsuitability for multi-pass deep drawing, insufficient strength, and few researches on aluminum alloy strips, and achieve excellent deep Excellent punching and deep drawing performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

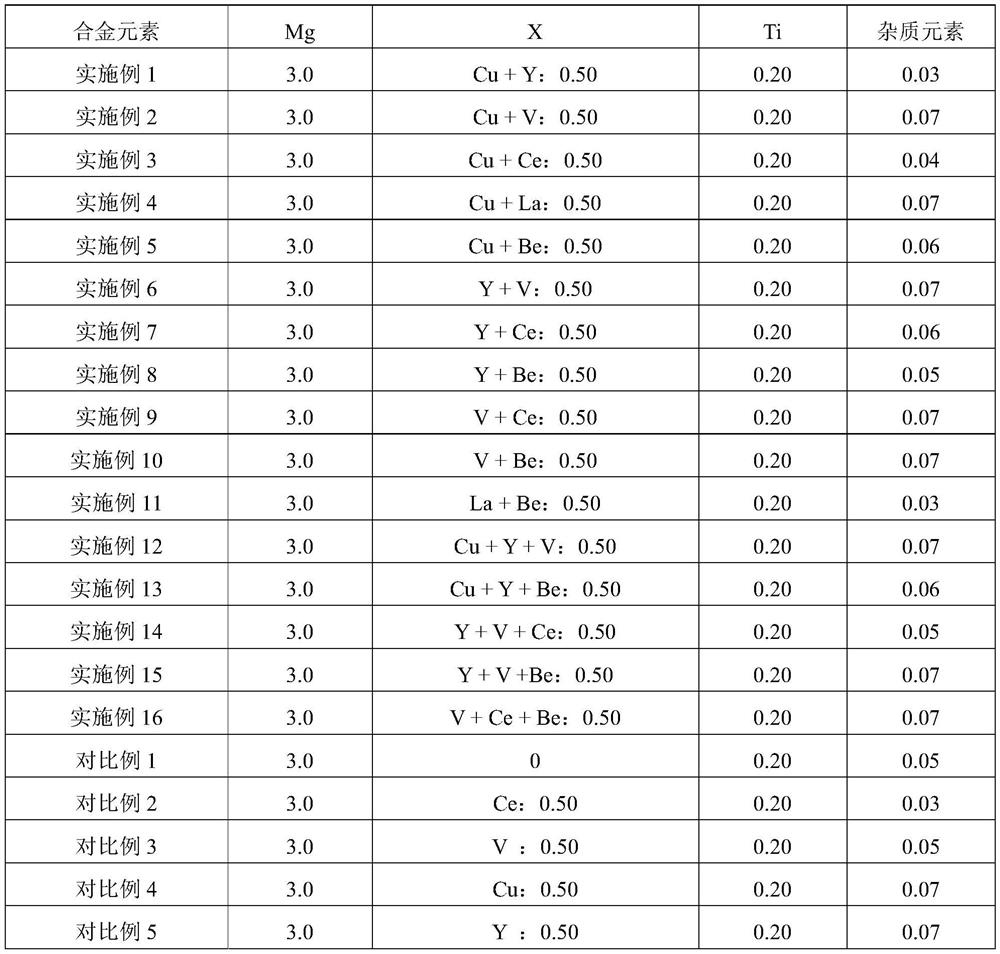

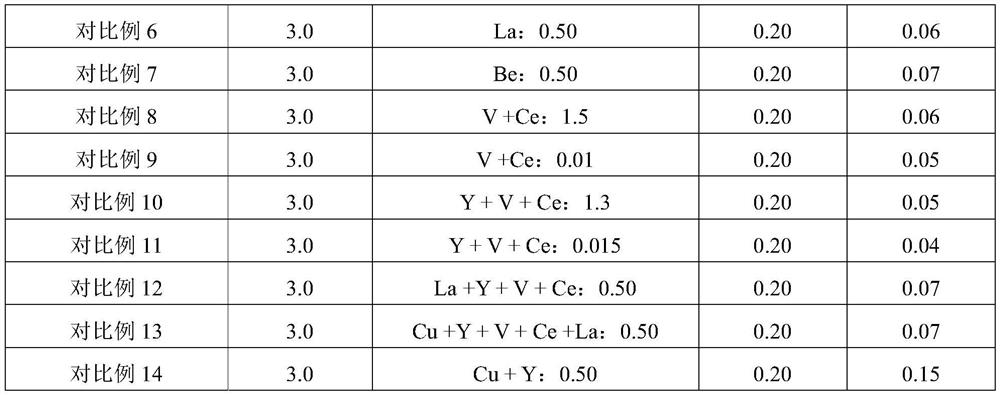

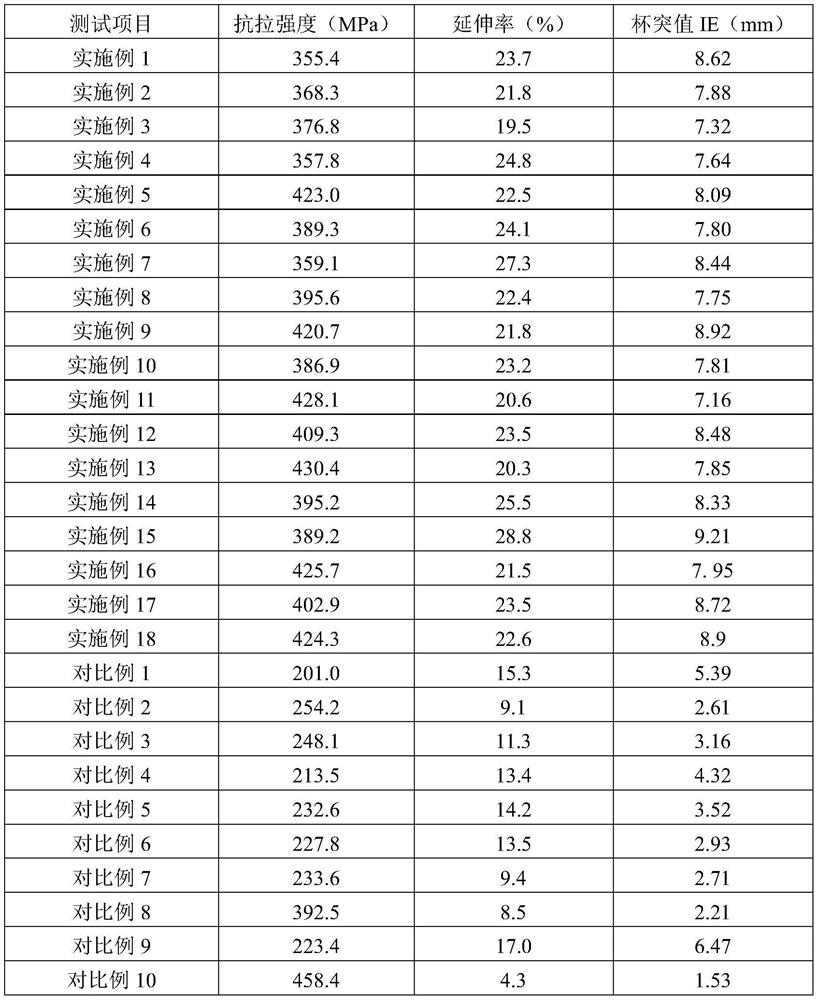

Examples

Embodiment 17

[0064] Aluminum alloy strips were prepared according to the alloy composition (Al-3.0%Mg-0.50%X(Y+V+Ce)-0.20%Ti) provided in Example 14 by the following method:

[0065] (1) Add Al, Mg, Ti and X into the high-purity graphite crucible of an intermediate frequency induction furnace according to the formula amount, and heat up to 750-800°C for non-vacuum melting according to the principle of melting high-melting point materials first and then cooling down to melt low-melting point materials, Among them, X is added into the furnace in the form of Mg-X or Al-Mg-X master alloy, and Ti is added into the furnace in the form of Al-Mg-3Ti master alloy. After all components are completely melted and mixed evenly, they are cast into iron molds. flat ingot;

[0066] (2) Put the slab obtained in step (1) into an intermediate frequency induction furnace to remelt, after conventional degassing, slag removal, and standing operations, pour the melt at 730-740°C into an iron mold for die casting...

Embodiment 18

[0070] Compared with Example 17, except that the vibration frequency in step (2) is controlled to be 30 Hz, and the vibration amplitude of the iron mold is 0.45 mm, other steps and conditions are exactly the same as in Example 17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com