Workpiece with aluminium-doped titanium diboride coating and preparation method thereof

A titanium diboride, aluminum doping technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problem that the high temperature oxidation resistance is not good enough, the thermal stability of the composite coating is poor, and the processing technology is complicated. and other problems to achieve the effect of improving high temperature oxidation resistance, increasing thermal stability and high temperature resistance, and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

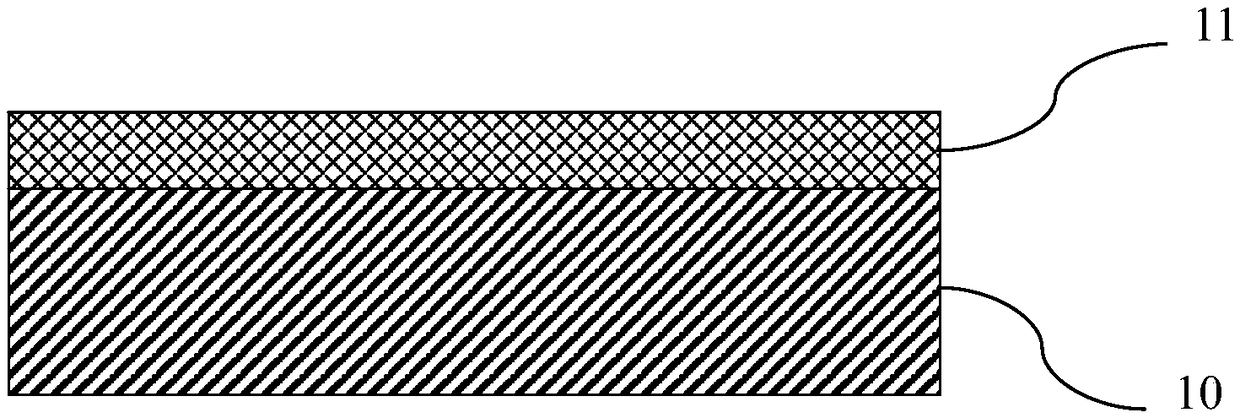

[0037] Such as figure 1 As shown, the workpiece with an aluminum-doped titanium diboride coating provided in Example 1 of the present invention includes a workpiece substrate 10 and an aluminum-doped titanium diboride coating 11 disposed on the workpiece substrate 10, so The aluminum-doped titanium diboride coating 11 includes a titanium diboride hard phase, and aluminum elements uniformly doped in the titanium diboride hard phase. Specifically, the workpiece substrate 10 in this embodiment is a cemented carbide tool.

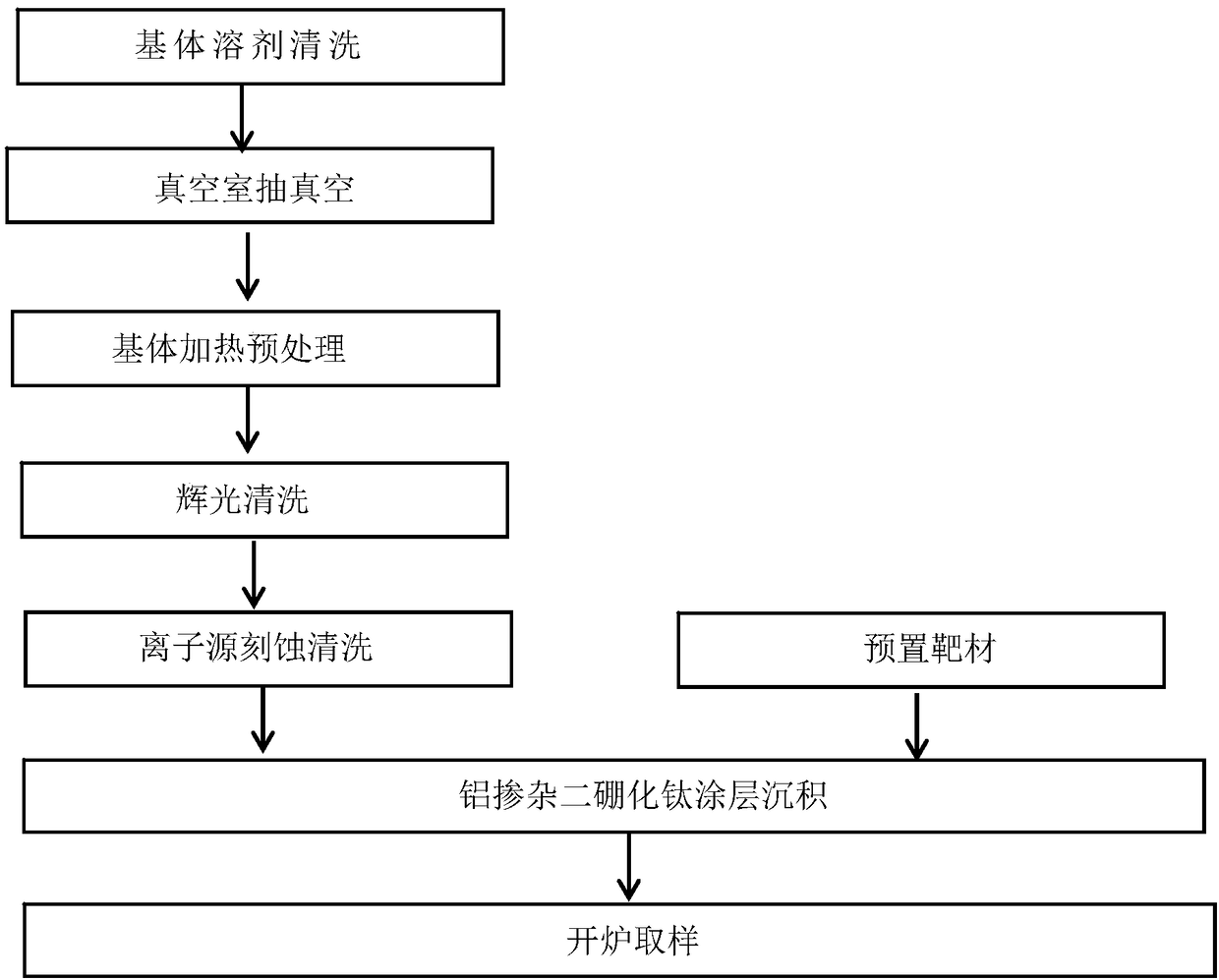

[0038] Such as figure 2 As shown, the preparation method of a cemented carbide tool with an aluminum-doped titanium diboride coating provided by an embodiment of the present invention includes the following steps:

[0039] 1. Preset target: aluminum target and TiB 2 The ceramic target is the target material. The Al target and TiB 2 The ceramic target is sputtered simultaneously, in which the atomic content of aluminum is 15 at.%, and the two targets are m...

Embodiment 2

[0046] A high-speed steel workpiece with an aluminum-doped titanium diboride coating, comprising a workpiece substrate and an aluminum-doped titanium diboride coating disposed on the workpiece substrate, the aluminum-doped titanium diboride coating comprising Titanium diboride hard phase, and aluminum element uniformly doped in the titanium diboride hard phase.

[0047] A method for preparing a high-speed steel workpiece with an aluminum-doped titanium diboride coating in an embodiment of the present invention includes the following steps:

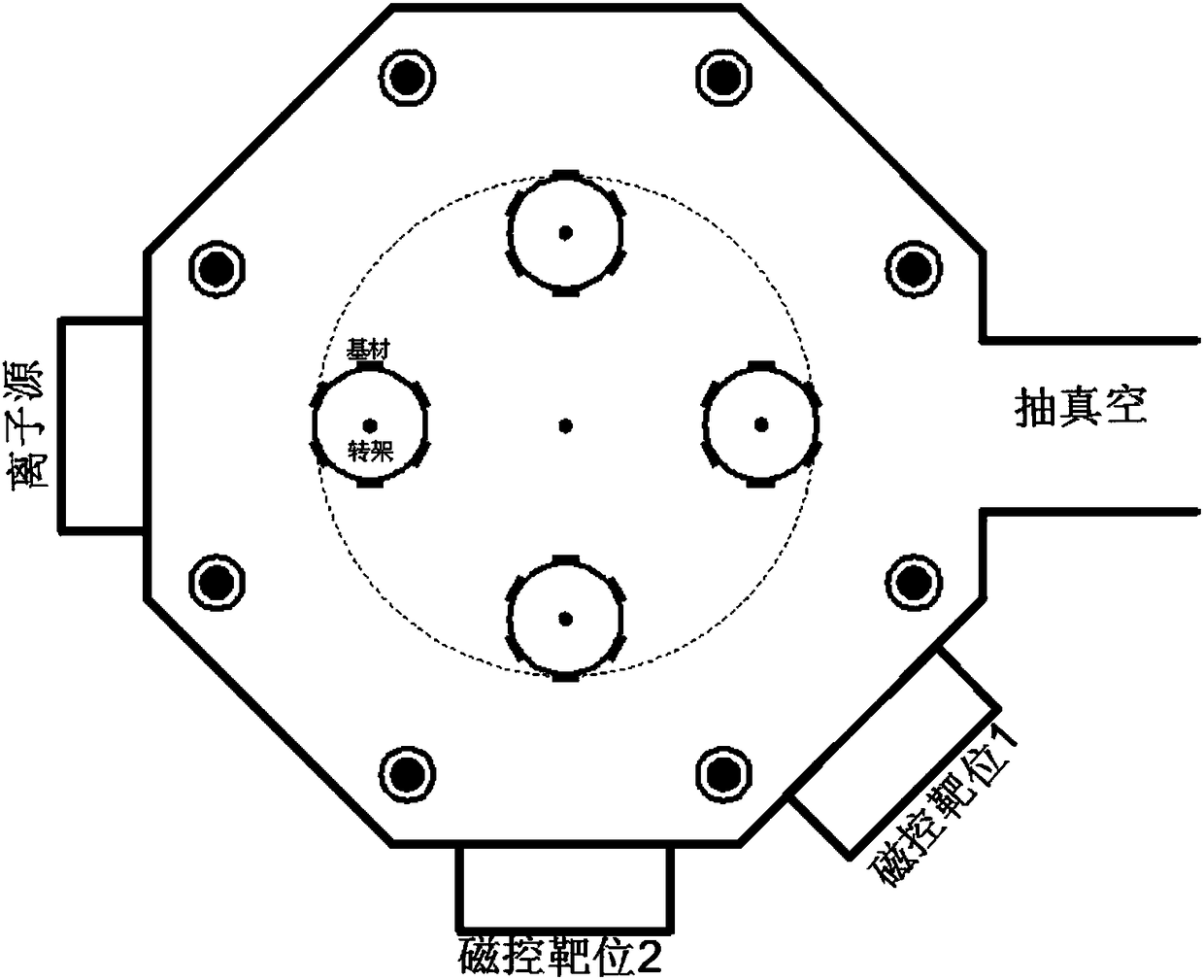

[0048] 1. Preset target: aluminum doped TiB 2 Ceramic targets are sputtering targets. The Al-doped TiB 2 The atomic content of aluminum in the ceramic target is 12 at.%, installed in such as image 3 Magnetron target position 1 of the magnetron sputtering coating equipment shown;

[0049] 2. Solvent cleaning: first put the high-speed steel in deionized water for ultrasonic cleaning for 15 minutes, then put it in acetone solution for ul...

Embodiment 3

[0055] A cubic boron nitride (CBN) turning tool with an aluminum-doped titanium diboride coating, comprising a workpiece substrate and an aluminum-doped titanium diboride coating arranged on the workpiece substrate, the aluminum-doped titanium diboride coating The heterotitanium diboride coating includes a titanium diboride hard phase, and aluminum elements uniformly doped in the titanium diboride hard phase.

[0056] The present embodiment has the preparation method of the cubic boron nitride (CBN) turning tool of aluminum-doped titanium diboride coating, comprises the following steps:

[0057] 1. Preset target material: aluminum target and TiB 2 When the ceramic target is the target material, the aluminum target and TiB 2 The ceramic target is sputtered at the same time, wherein the atomic content of aluminum is 25 at.%, and the two targets are installed in such as image 3 Magnetron target position 1 and magnetron target position 2 of the magnetron sputtering coating equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com