Rare-earth salt and zeolite doped silane composite film and preparation and application methods thereof

A technology of composite film and rare earth salt, which is applied in the direction of metal material coating process, etc., can solve the problem of no silane composite film, etc., and achieve the effect of high reproducibility, improved corrosion resistance, and non-pollution conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Sample pretreatment

[0072] Cut the 7N01 aluminum alloy into 15×15×2mm samples, boil them in boiling water, polish them with water abrasive paper, and then ultrasonically clean them in absolute ethanol and deionized water;

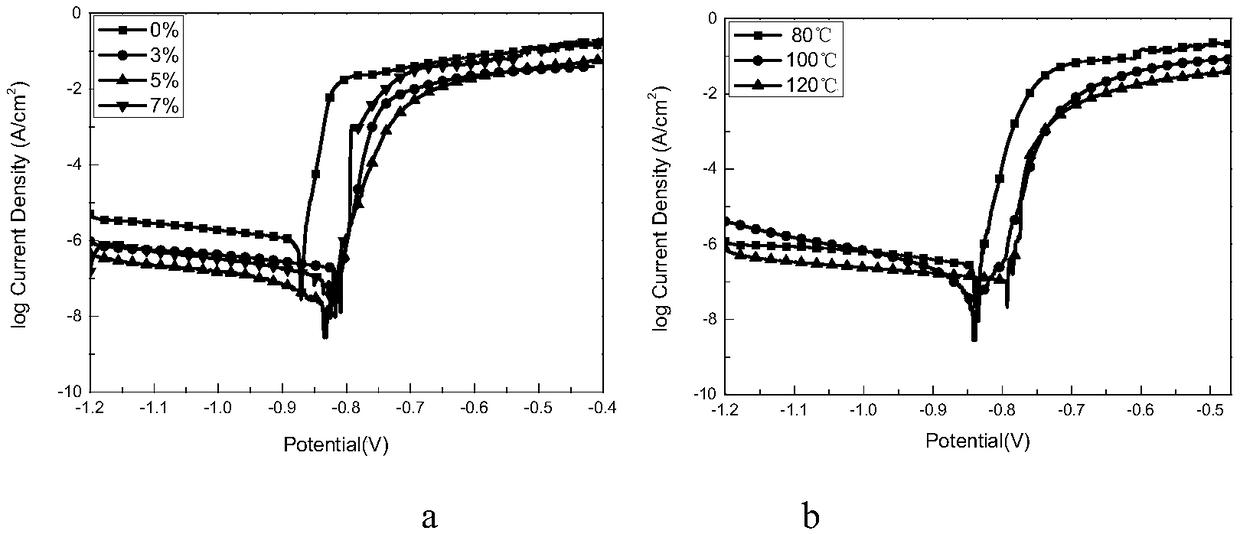

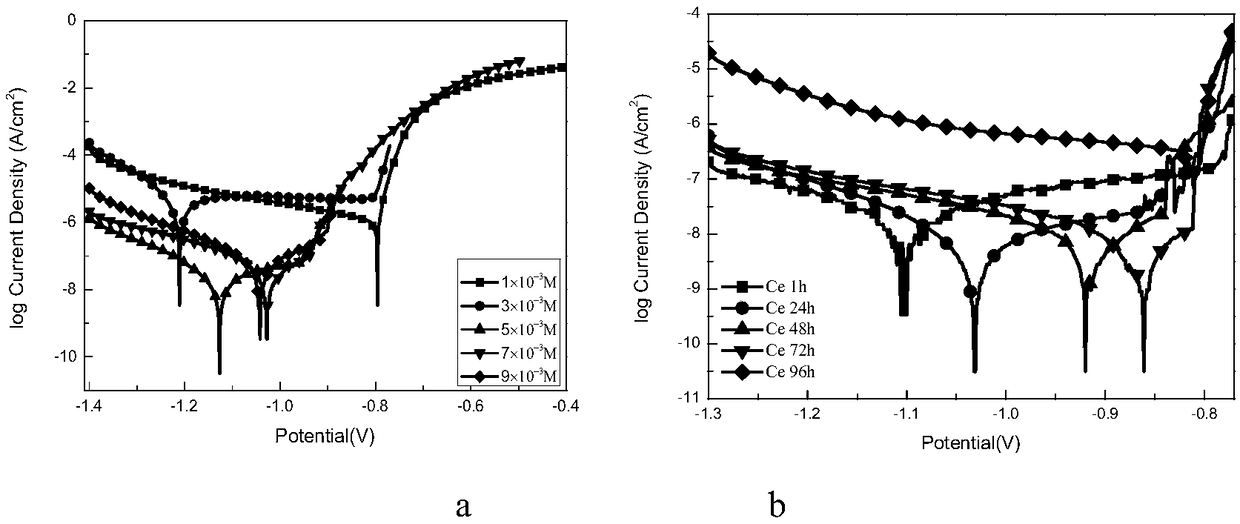

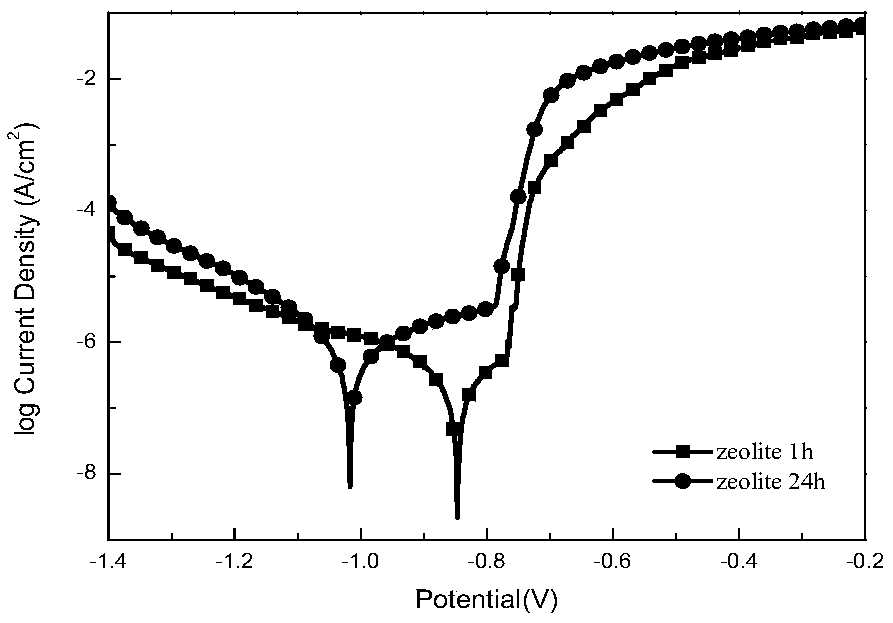

[0073] (2) Preparation of silane mixture

[0074] Mix ethanol, bis-(γ-triethoxysilylpropyl) tetrasulfide silane, and deionized water in a volume ratio of 90:5:5, and the concentration is 1×10 -3 Add mol / L cerium nitrate to the mixture, age at room temperature for 3 days, add 0.1 g / L zeolite nanoparticles into the mixture, stir for 2 minutes and then ultrasonicate for 2 minutes to obtain a silane mixture;

[0075] (3) Curing of silane composite film

[0076] Put the pretreated aluminum alloy sample into the aged silane mixture, take it out after soaking for 1 min, put it in an oven and cure it at 80°C for 1 h to form a silane composite film.

Embodiment 2

[0078] (1) Sample pretreatment

[0079] Cut the 7020 aluminum alloy into 15×15×2mm samples, boil them in boiling water, polish them with water abrasive paper, and then ultrasonically clean them in absolute ethanol and deionized water;

[0080] (2) Preparation of silane mixture

[0081] Mix ethanol, bis-(γ-triethoxysilylpropyl) tetrasulfide silane, and deionized water evenly in a volume ratio of 90:5:5, and the concentration is 5×10 -3 Add mol / L cerium nitrate to the mixture, age at room temperature for 1 day, add 0.1 g / L zeolite nanoparticles into the mixture, stir for 2 minutes and then ultrasonicate for 2 minutes to obtain a silane mixture;

[0082] (3) Curing of silane composite film

[0083] Put the pretreated aluminum alloy sample into the aged silane mixture, take it out after soaking for 1 min, put it in an oven and cure it at 60°C for 1 h to form a silane composite film.

Embodiment 3

[0085] (1) Sample pretreatment

[0086] Cut the 6063 aluminum alloy into 15×15×2mm samples, boil them in boiling water, polish them with water abrasive paper, and then ultrasonically clean them in absolute ethanol and deionized water;

[0087] (2) Preparation of silane mixture

[0088]Mix ethanol, bis-(γ-triethoxysilylpropyl) tetrasulfide silane, and deionized water in a volume ratio of 85:5:10, and the concentration is 9×10 -3 Add mol / L cerium nitrate into the mixture, age at room temperature for 2 days, add zeolite nanoparticles into the mixture at 0.5 g / L, stir for 2 minutes and then sonicate for 2 minutes to obtain a silane mixture;

[0089] (3) Curing of silane composite film

[0090] Put the pretreated aluminum alloy sample into the aged silane mixture, take it out after soaking for 1min, put it in an oven and cure it at 119°C for 1h to form a silane composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com