A silicon-titanium-fluorine co-doped lithium nickel cobalt oxide cathode material and a preparation method thereof

A lithium nickel cobalt oxide and positive electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of uneven discharge, poor safety performance, and short cycle life of materials, and achieve improved cycle performance and discharge specific capacity. Increased structural stability and extended safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

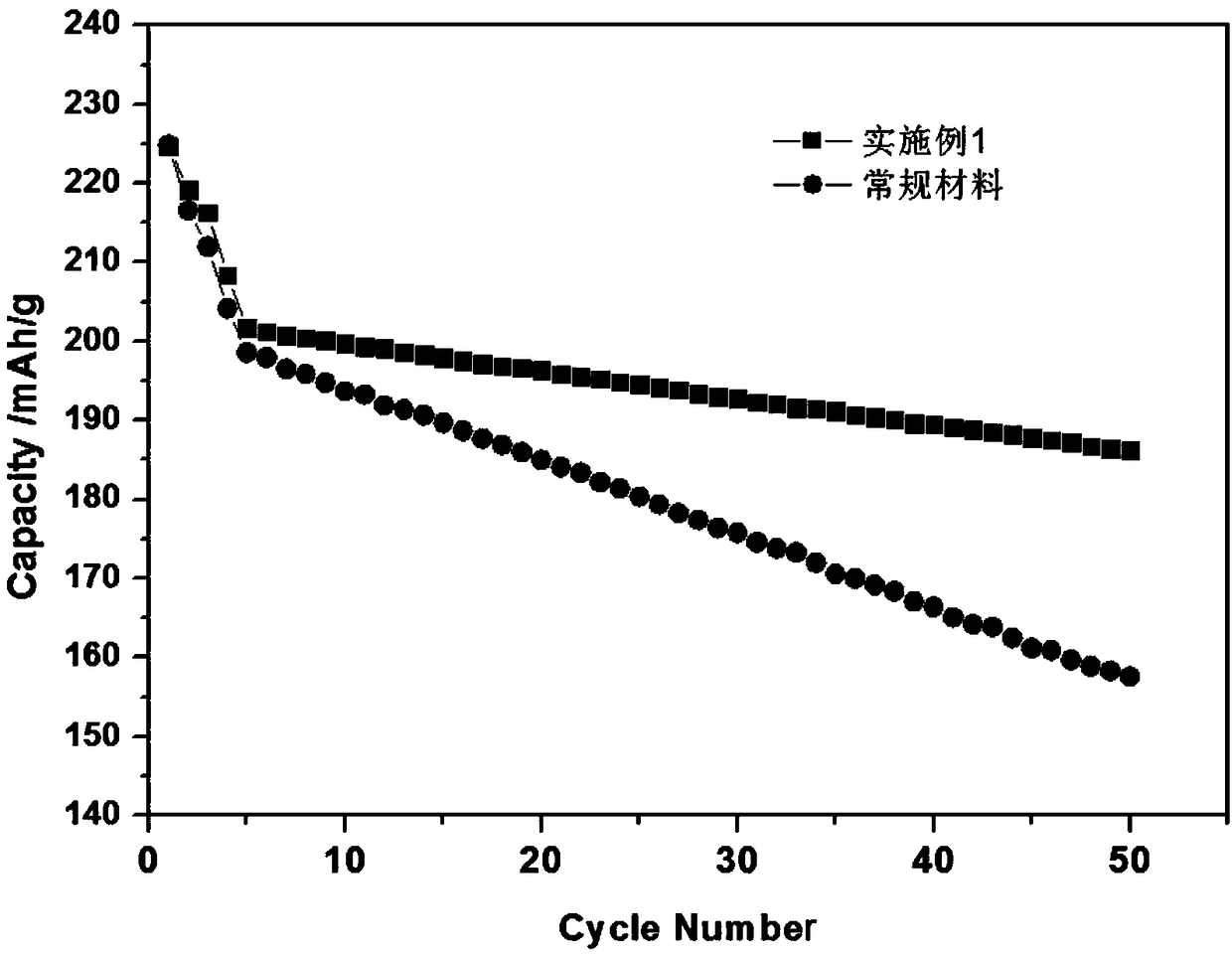

Embodiment 1

[0035] Preparation of LiNi 0.9 co 0.05 Si 0.03 Ti 0.02 o 1.95 f 0.05 Cathode material (where the average valence state of nickel is between +2 and +3);

[0036] Step 1, first weigh the nickel-cobalt composite precursor (composite hydroxide of nickel and cobalt) with a molar ratio of nickel and cobalt of 18:1, and then weigh it according to 3.16% of the total molar amount of nickel and cobalt in the nickel-cobalt composite precursor. Take silicon dioxide, weigh titanium dioxide according to 2.11% of the total molar weight of nickel and cobalt in the nickel-cobalt composite precursor, weigh ammonium fluoride according to 5.26% of the total molar weight of nickel and cobalt in the cobalt composite precursor, and weigh according to the molar ratio of lithium : Me (the sum of nickel and cobalt molar weights)=1.05:1 takes lithium nitrate and sets aside;

[0037] Step 2, adding the nickel-cobalt composite precursor, silicon dioxide, titanium dioxide, and ammonium fluoride in st...

Embodiment 2

[0041] Preparation of LiNi 0.9 co 0.05 Si 0.03 Ti 0.02 o 1.95 f 0.05 Cathode material (where the average valence state of nickel is between +2 and +3);

[0042] Step 1, first weigh the nickel-cobalt composite precursor (composite hydroxide of nickel and cobalt) with a molar ratio of nickel and cobalt of 18:1, and then weigh it according to 3.16% of the total molar amount of nickel and cobalt in the nickel-cobalt composite precursor. Take silicon dioxide, weigh titanium dioxide according to 2.11% of the total molar weight of nickel and cobalt in the nickel-cobalt composite precursor, weigh ammonium fluoride according to 5.26% of the total molar weight of nickel and cobalt in the nickel-cobalt composite precursor, and weigh according to the molar ratio Lithium: Me (the sum of nickel and cobalt molar weights) = 1.05: 1 Weigh lithium nitrate and set aside;

[0043] Step 2, adding the nickel-cobalt composite precursor, silicon dioxide, titanium dioxide, and ammonium fluoride in...

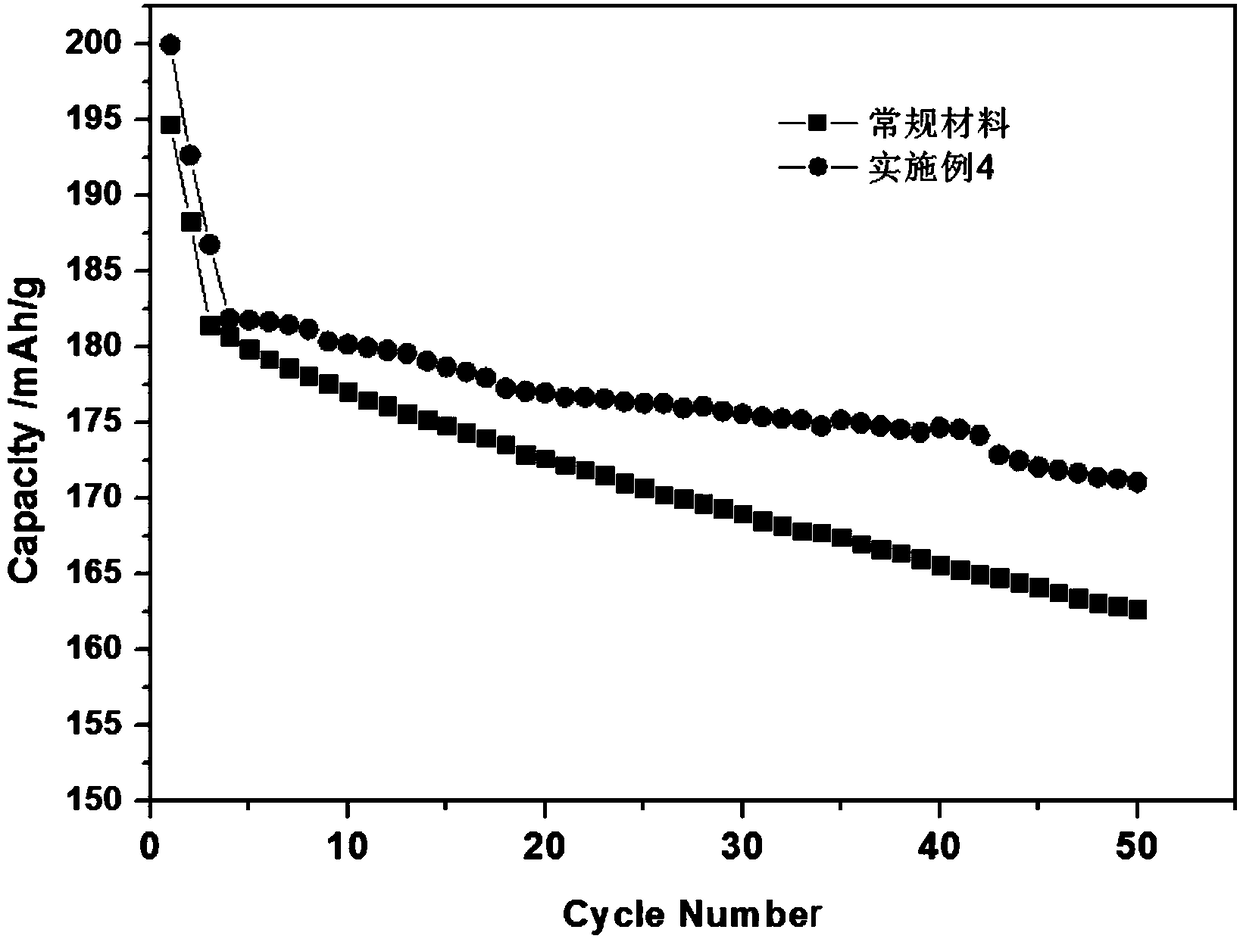

Embodiment 3

[0047] Preparation of LiNi 0.9 co 0.05 Si 0.03 Ti 0.02 o 1.95 f 0.05 Cathode material (where the average valence state of nickel is between +2 and +3);

[0048] Step 1, first weigh the nickel-cobalt composite precursor (composite hydroxide of nickel and cobalt) with a molar ratio of nickel and cobalt of 18:1, and then weigh it according to 3.16% of the total molar amount of nickel and cobalt in the nickel-cobalt composite precursor. Take silicon dioxide, weigh titanium dioxide according to 2.11% of the total molar weight of nickel and cobalt in the nickel-cobalt composite precursor, weigh ammonium fluoride according to 5.26% of the total molar weight of nickel and cobalt in the nickel-cobalt composite precursor, and weigh according to the molar ratio Lithium: Me (the sum of nickel and cobalt molar weights) = 1.05: 1 Weigh lithium nitrate and set aside;

[0049] Step 2, adding the nickel-cobalt composite precursor, silicon dioxide, titanium dioxide, and ammonium fluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com