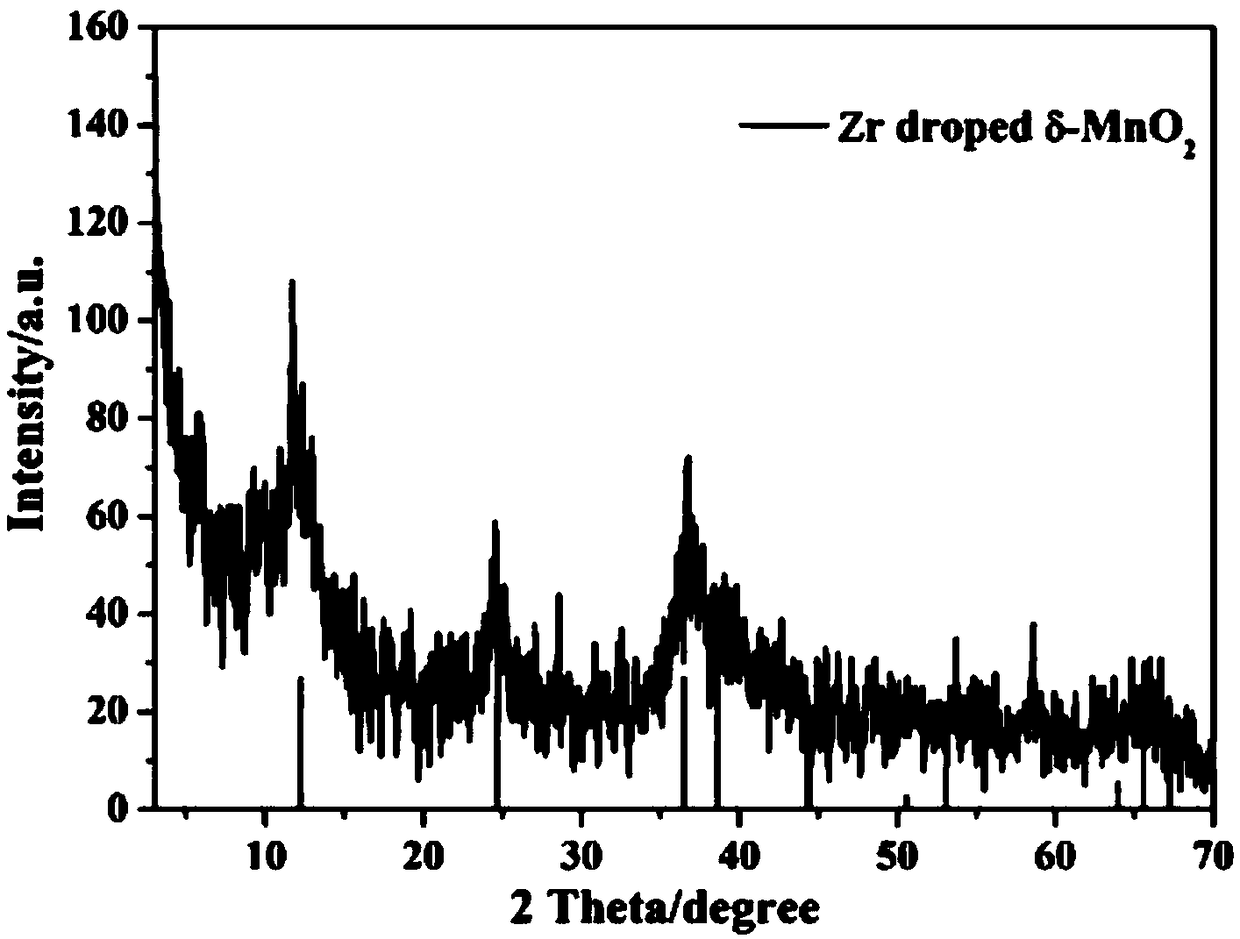

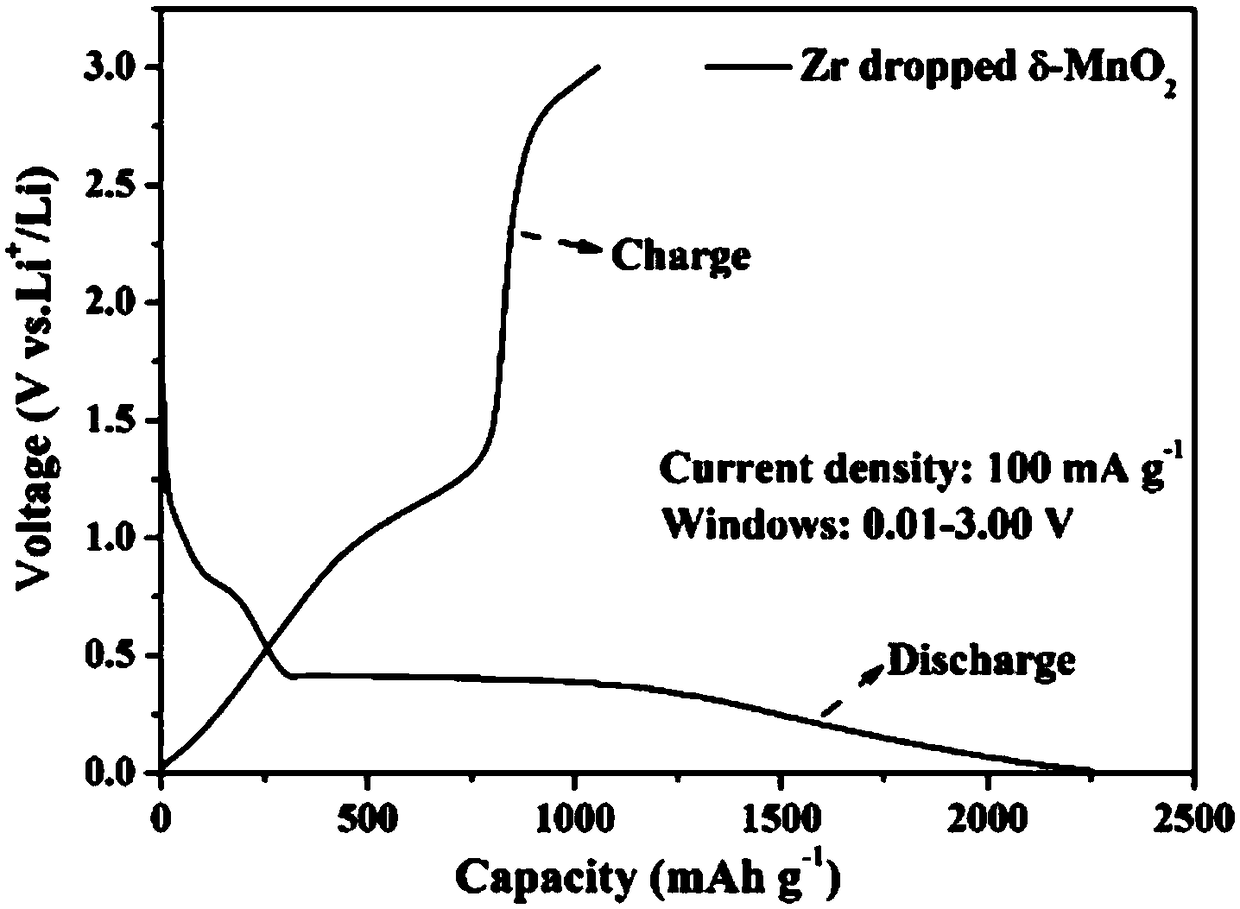

A method for preparing Zr4+-doped delta-MnO2 nanoporous material

A nanoporous, mnso4·h2o technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unfavorable charge transfer, low electronic conductivity, powdering of electrode materials, etc., to achieve Improved electrochemical performance, simple preparation process, and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Weigh 0.01gMnSO 4 ·H 2 O with 0.047g KMnO 4 , Measure 30mL of deionized water, prepare a mixed solution, stir for 5min to make it evenly mixed.

[0021] Step 2: Add 0.001g of Zr(NO 3 ) 2 ·5H 2 O, stir for 5min to make it evenly mixed.

[0022] Step 3: transfer the mixed solution obtained in step 2 into a high-pressure reactor, and control the volume of the solution at 60% of the volume of the reactor.

[0023] Step 4: After the reaction kettle was reacted at 140°C for 12 hours, the temperature was lowered, and the obtained product was first washed with distilled water to neutrality, then washed with absolute ethanol, and finally dried in an oven to obtain Zr 4+ Doped δ-MnO 2 nanoporous materials.

Embodiment 2

[0025] Step 1: Weigh 0.047g MnSO 4 ·H 2 O with 0.28 g KMnO 4 , Measure 35mL of deionized water, prepare a mixed solution, stir for 5min to make it evenly mixed.

[0026] Step 2: Add 0.045g of Zr(NO 3 ) 2 ·5H 2 O, stir for 5min to make it evenly mixed.

[0027] Step 3: transfer the mixed solution obtained in step 2 into a high-pressure reactor, and control the volume of the solution at 70% of the volume of the reactor.

[0028] Step 4: After the reaction kettle was reacted at 180°C for 20 hours, cooled down, the obtained product was first washed with distilled water to neutrality, then washed with absolute ethanol, and finally dried in an oven to obtain Zr 4+ Doped δ-MnO 2 nanoporous materials.

Embodiment 3

[0030] Step 1: Weigh 0.019g MnSO 4 ·H 2 O with 0.119g KMnO 4 , Measure 37.5mL of deionized water, prepare a mixed solution, stir for 5min to make it evenly mixed.

[0031] Step 2: Add 0.023g of Zr(NO 3 ) 2 ·5H 2 O, stir for 5min to make it evenly mixed.

[0032] Step 3: transfer the mixed solution obtained in step 2 into an autoclave, and control the volume of the solution at 75% of the volume of the autoclave.

[0033] Step 4: After the reaction kettle was reacted at 120°C for 16 hours, it was cooled down, and the obtained product was first washed with distilled water to neutrality, then washed with absolute ethanol, and finally dried in an oven to obtain Zr 4+ Doped δ-MnO 2 nanoporous materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com