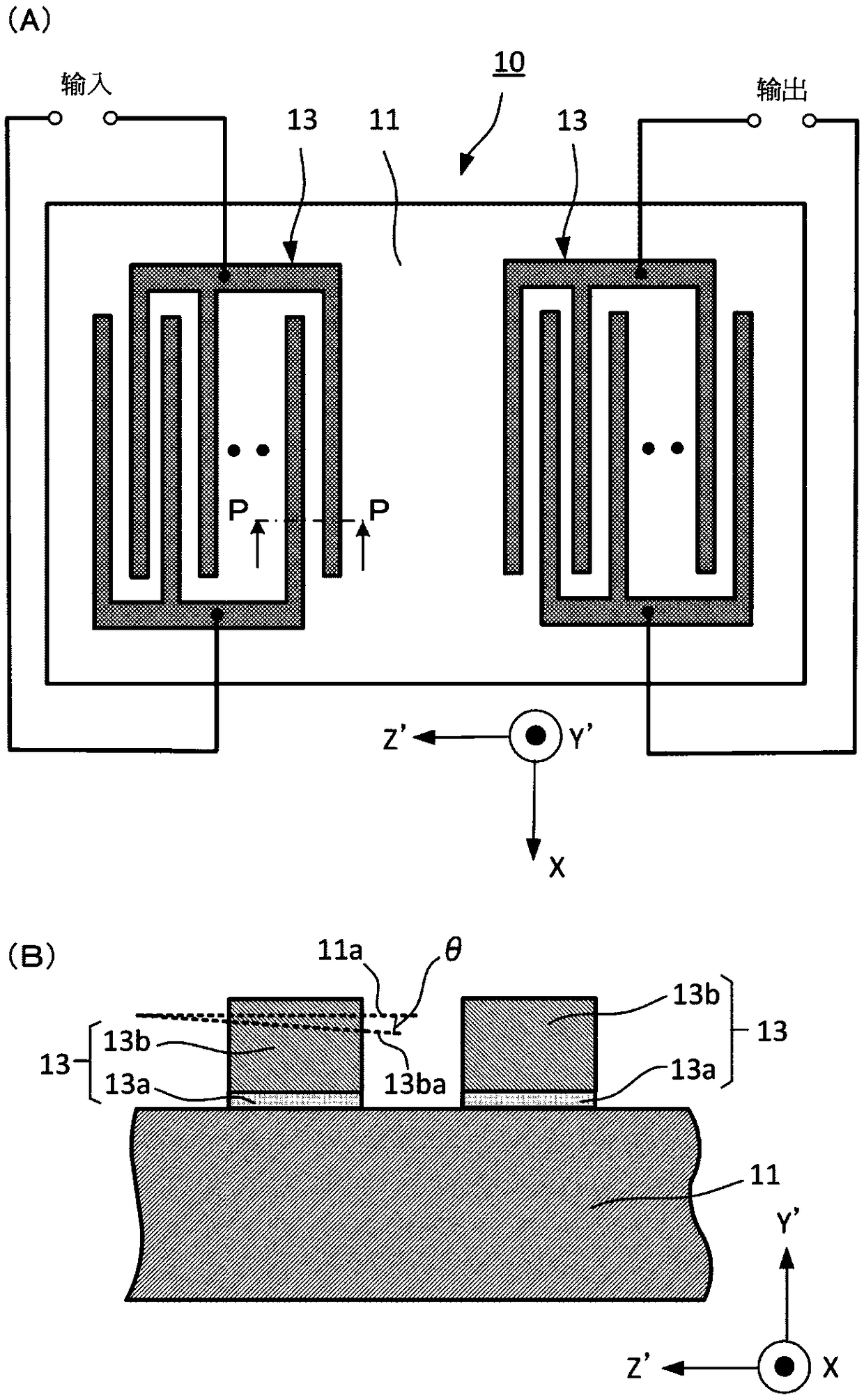

Surface acoustic wave device and method for manufacturing the same

A technology of surface acoustic wave and manufacturing method, which is applied in the manufacturing/assembly of electrical components, piezoelectric/electrostrictive devices, chemical instruments and methods, etc., can solve the problems of electrical resistance deterioration of filters and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

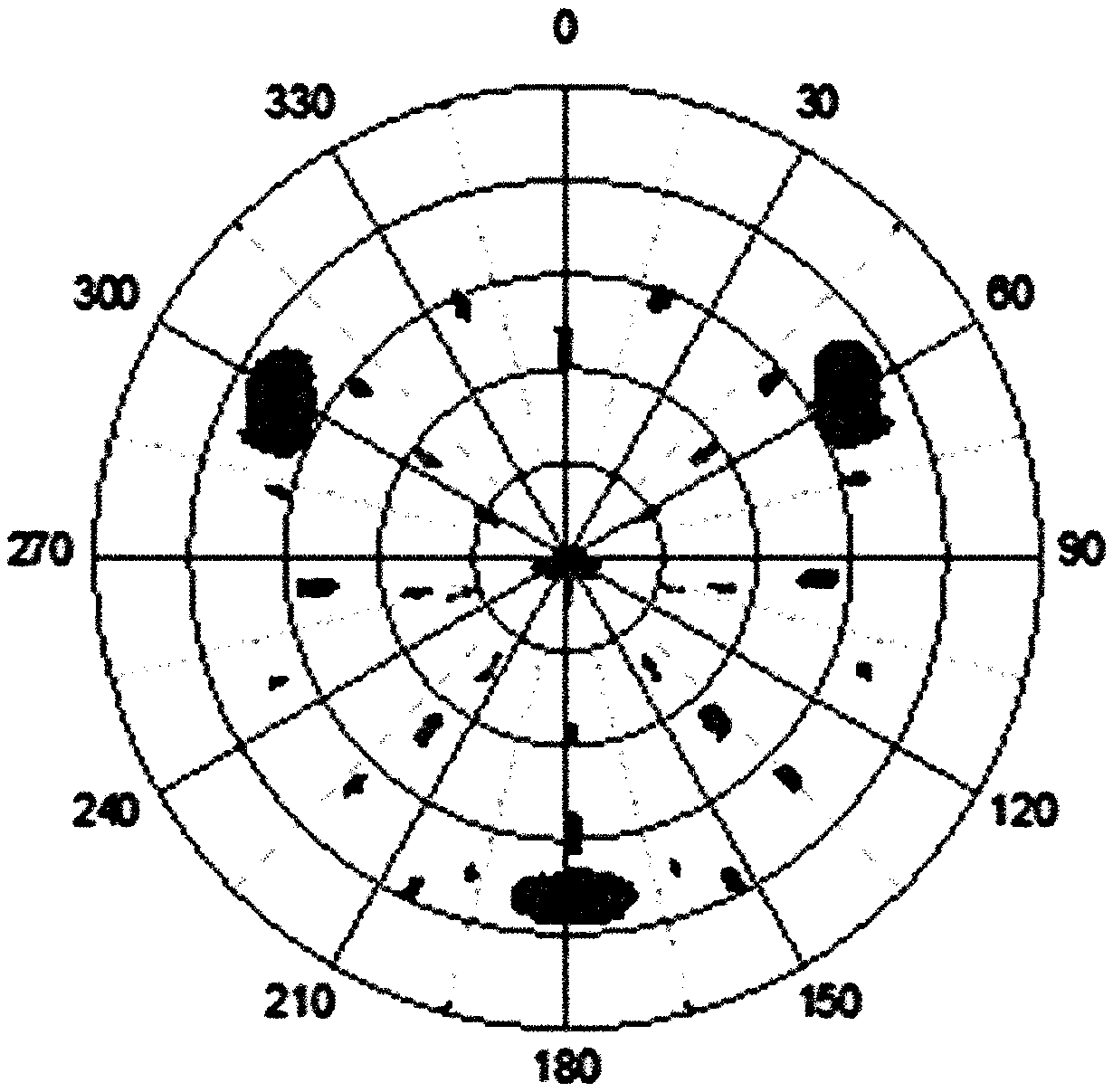

[0092] As Example 2, the piezoelectric single crystal substrate is set to 36 degrees Y-cut LiTaO 3 Examples of substrates are described. Ready as 36 degree Y-cut LiTaO 3 The main surface of the substrate is ground to a polished surface by mechanical polishing. The substrate was ultrasonically cleaned with pure water in the same manner as in Example 1, then introduced into a DC magnetron sputtering apparatus, and a titanium film and an Al-0.5Cu film were sequentially laminated. Here, the film forming rate of the titanium film was fixed at 0.23 nm / sec and the thickness of the Ti film was varied within the range of 2 nm to 50 nm. The film thickness of the Al-0.5Cu film is the same as in Example 1. In addition, the film formation rate was obtained by setting the film formation conditions of the titanium film as an argon flow rate of 50 sccm and a DC power of 300W. The substrate temperature was set to room temperature in the same manner as in Example 1.

[0093] About the prod...

Embodiment 3

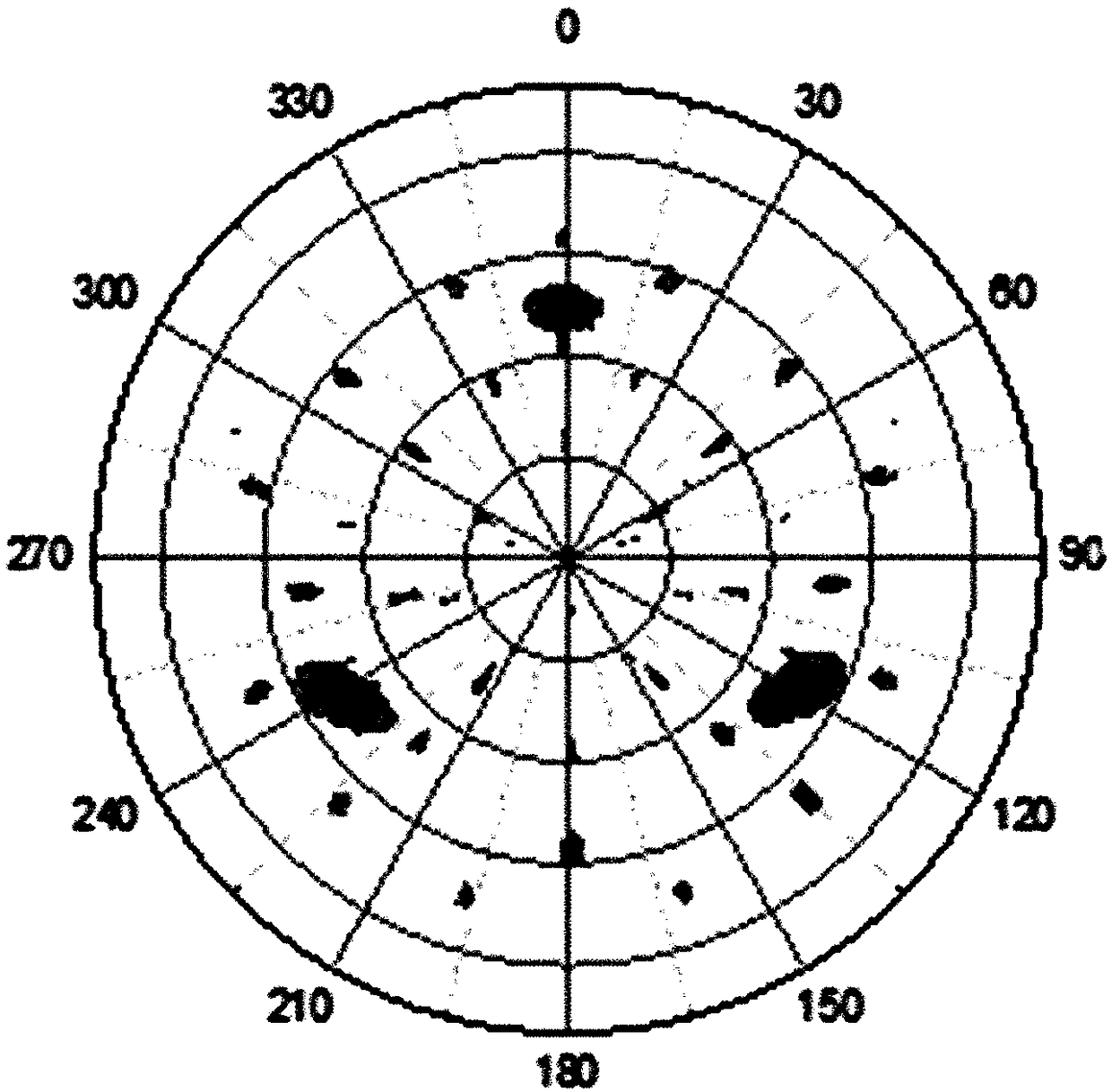

[0099] As Example 3, the piezoelectric single crystal substrate is set to 50 degrees Y-cut LiTaO 3 Examples of substrates are described. Ready as 50 degree Y-cut LiTaO 3 The main surface of the substrate is ground to a polished surface by mechanical polishing. The substrate was ultrasonically cleaned with pure water in the same manner as in Example 1, then introduced into a DC magnetron sputtering apparatus, and a titanium film and an Al-0.5Cu film were sequentially laminated. Here, the film forming rate of the titanium film was fixed at 0.50 nm / sec and the thickness of the Ti film was varied within the range of 5 nm to 50 nm. The film thickness of the Al-0.5Cu film is the same as in Example 1. In addition, the film formation rate was obtained by setting the film formation conditions of the titanium film as an argon flow rate of 50 sccm and a DC power of 500 W. The substrate temperature was set to room temperature in the same manner as in Example 1.

[0100] About the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com