Composite photocatalytic material of carbon nitride and bismuth oxyhalide and preparation method of composite photocatalytic material

A composite photocatalysis, bismuth oxyhalide technology, applied in chemical instruments and methods, physical/chemical process catalysts, special compound water treatment, etc., can solve the problems that have not been reported in the literature, and achieve easy operation, environmental friendliness, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] g-C of the present invention 3 N 4 with BiOX a Y b The preparation method of composite photocatalytic material comprises the following steps:

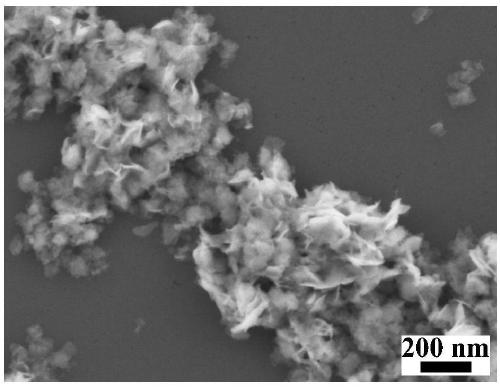

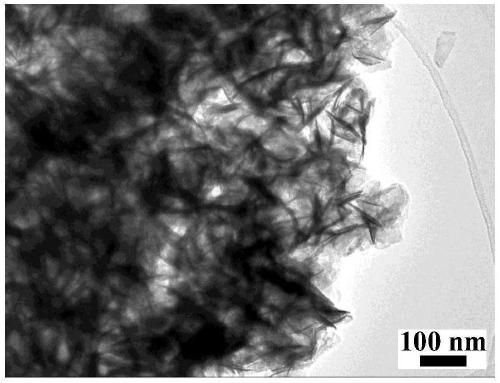

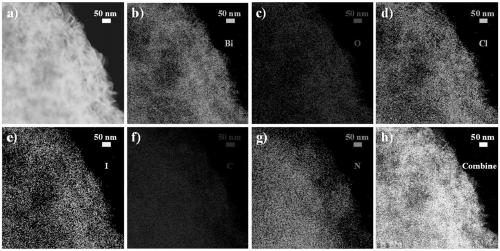

[0034] 2gg-C 3 N 4 The precursor melamine was put in a covered crucible and calcined at 550 °C for 2 h in a muffle furnace. 0.3 g g-C 3 N 4 After mixing with 25 mL of deionized water, sonicate for 30 min, and transfer to g-C at 80°C 3 N 4 Add 5.8gBi(NO 3 ) 3 ·5H 2 O, 0.5g PVP and 25mL glycerin were mixed for 30min, then 100mL mixed solution of 0.67gKCl and 0.50g KI (KCl and KI total 12mmol) was added dropwise, the pH was adjusted to 9.0 with ammonia water, and the reaction was continued at 80°C for 1h . The reacted sample was filtered and washed 3 times, then dried and ground to obtain g-C 3 N 4 with BiOX a Y b Composite photocatalytic material ( figure 1 , figure 2 and image 3 ).

[0035] The composite photocatalytic material was used to degrade 10 mg / L bisphenol A (BPA) solution, and the degradation rate...

Embodiment 2

[0037] In this embodiment, g-C in step (2) 3 N 4 The mass is 0.2 g, and other steps are the same as in Example 1.

[0038] The composite photocatalytic material was used to degrade 10 mg / LBPA solution, and the degradation rate of BPA was 96.8 % under visible light for 30 min ( Figure 5 ).

Embodiment 3

[0040] In this embodiment, g-C in step (2) 3 N 4 The mass is 0.4 g, and other steps are the same as in Example 1.

[0041] The composite photocatalytic material was used to degrade 10 mg / LBPA solution, and the degradation rate of BPA was 93.6% under visible light for 30 min ( Figure 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com