Starch-based material with cold water soluble characteristic and preparation and application thereof

A starch-based, water-soluble technology, applied in the field of starch-based materials and their preparation, can solve the problems of insolubility, poor arrangement tightness and poor water solubility, and achieve the effects of improving compatibility, improving water-solubility, and increasing plasticizing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

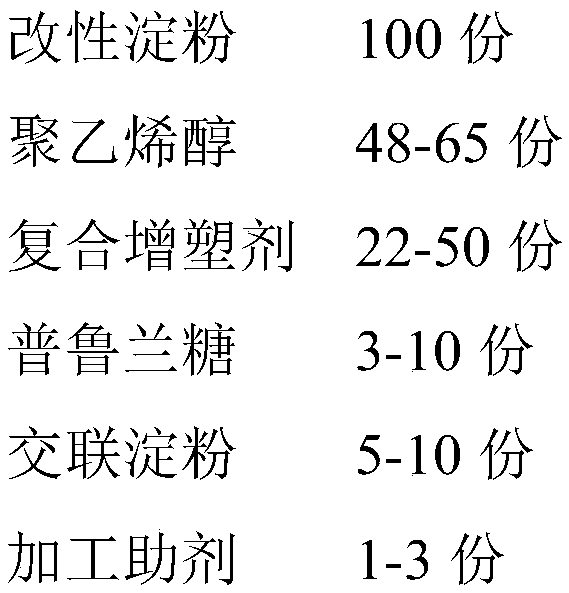

[0047] A starch-based material with cold water soluble properties, in parts by weight, comprising the following components:

[0048]

[0049] (1) Weigh the components according to the parts by weight, add the modified starch, polyvinyl alcohol and processing aid PEG-6000 to the high-speed mixer, start the low-speed stirring, add and mix, and then start the high-speed stirring;

[0050] (2) Under high-speed stirring, slowly add compound plasticizer and pullulan, and keep stirring at high speed after adding; then switch to low speed, and add the remaining components: cross-linked starch; continue to start high-speed after adding all the components Stir, cool down and discharge the material, enter the twin-screw extrusion granulator for extrusion and granulation, and obtain the starch-based material with cold water soluble properties.

[0051] Further, in step (1), the mixing time is 3 minutes.

[0052] Further, in step (1), the time of the high-speed stirring is 5 minutes. ...

Embodiment 2

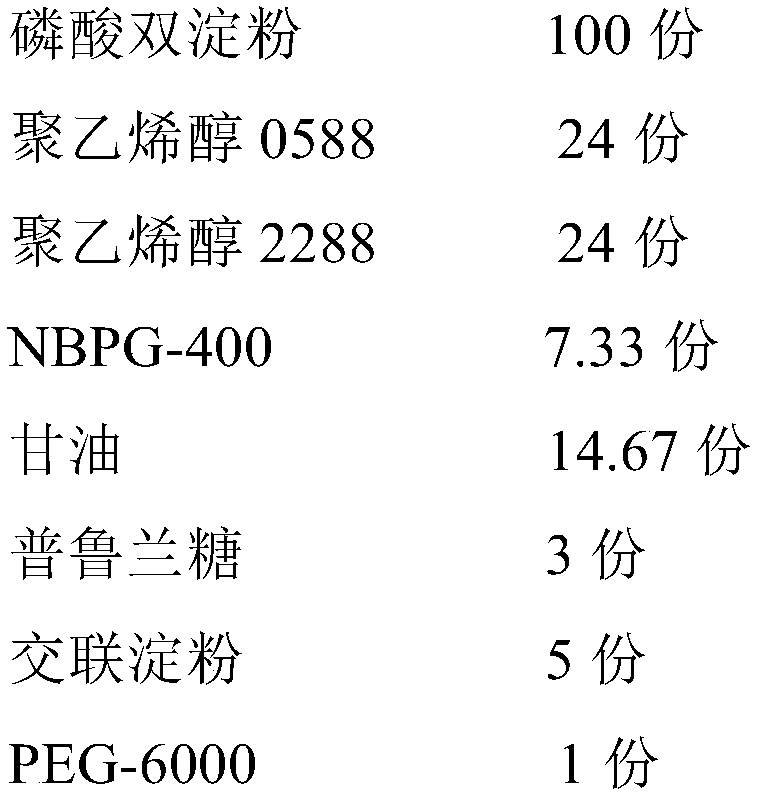

[0062] A starch-based material with cold water soluble properties, in parts by weight, comprising the following components:

[0063]

[0064] (1) Weigh the components according to the parts by weight, add the modified starch, polyvinyl alcohol and processing aid PEG-2000 to the high-speed mixer, start the low-speed stirring, add and mix, and then start the high-speed stirring;

[0065] (2) Under high-speed stirring, slowly add compound plasticizer and pullulan, and keep stirring at high speed after adding; then switch to low speed, and add the remaining components: cross-linked starch; continue to start high-speed after adding all the components Stir, cool down and discharge the material, enter the twin-screw extrusion granulator for extrusion and granulation, and obtain the starch-based material with cold water soluble properties.

[0066] Further, in step (1), the mixing time is 3 minutes.

[0067] Further, in step (1), the time of the high-speed stirring is 5 minutes. ...

Embodiment 3

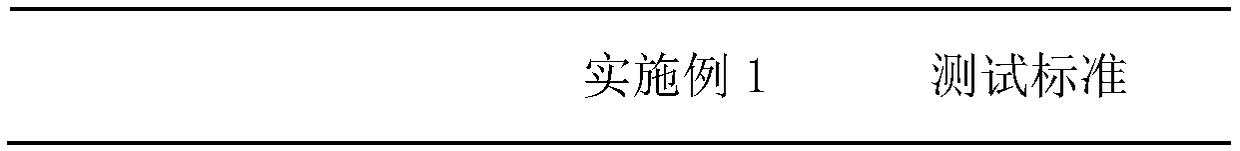

[0076] A starch-based material with cold water soluble properties, in parts by weight, comprising the following components:

[0077]

[0078]

[0079] (1) Weigh the components according to the parts by weight, add the modified starch, polyvinyl alcohol and processing aid PEG-4000 to the high-speed mixer, start the low-speed stirring, add and mix, and then start the high-speed stirring;

[0080] (2) Under high-speed stirring, slowly add compound plasticizer and pullulan, and keep stirring at high speed after adding; then switch to low speed, and add the remaining components: cross-linked starch; continue to start high-speed after adding all the components Stir, cool down and discharge the material, enter the twin-screw extrusion granulator for extrusion and granulation, and obtain the starch-based material with cold water soluble properties.

[0081] Further, in step (1), the mixing time is 3 minutes.

[0082] Further, in step (1), the time of the high-speed stirring is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com