Controllable starch-based biodegradable agricultural mulching film

A biodegradable and agricultural mulch technology, applied in applications, plant protection, plant protection covers, etc., can solve the problems of difficult control of degradation time and degradation efficiency, decline in cultivated land quality, laborious manual recycling, etc., and achieve good biodegradation performance , promote microbial metabolism, and improve the effect of microclimate under the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 uses the following mass ratio of raw materials: PBAT (74.8%), PLA (25%), chain extender (0.1%), release agent (0.1%), wherein the chain extender is German BASF ADR-4370S , the release agent is Tianshi wax powder PEW-0300; the following method is used to prepare the film of the present invention: 50 ℃ hot air drying raw materials PBAT, PLA, add chain extender, release agent and stir at high speed, mix into a premix, Extrude, modify and granulate with a twin-screw extruder, and use a horizontal film-drawing machine to carry out film-drawing, cutting, packaging, field filming, and investigation of the degradation time and degradation efficiency of the modified material.

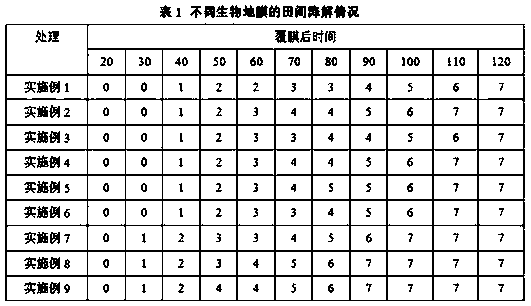

[0036] On April 20, 2017, the film degradation test site was selected at the Zhanjiang Experimental Station of the Chinese Academy of Tropical Agricultural Sciences in Mazhang District, Zhanjiang City, Guangdong Province. Using the aforementioned investigation method of the present invention, the...

Embodiment 2

[0038] Example 2 uses the following mass ratio of raw materials: PBAT (79.5%), PLA (20%), chain extender (0.3%), release agent (0.2%), wherein the chain extender is German BASF ADR-4370S , the release agent is Tianshi wax powder PEW-0300; the following method is used to prepare the film of the present invention: 50 ℃ hot air drying raw materials PBAT, PLA, add chain extender, release agent and stir at high speed, mix into a premix, Extrude, modify and granulate with a twin-screw extruder, and use a horizontal film-drawing machine to carry out film-drawing, cutting, packaging, field filming, and investigation of the degradation time and degradation efficiency of the modified material.

[0039] Using the same method as in Example 1, it was found that the induction period of the mulch film was 40 days, and cracks began to appear on the 40th day after film covering, and reached a grade 3 degradation degree at 60 days of film covering, and large cracks of 50 cm appeared in the film ...

Embodiment 3

[0040] Example 3 uses the following mass ratio raw materials: PBAT (65%), PLA (15%), chain extender (10%), release agent (10%), wherein the chain extender is German BASF ADR-4370S , the release agent is Tianshi wax powder PEW-0300; the following method is used to prepare the film of the present invention: 50 ℃ hot air drying raw materials PBAT, PLA, add chain extender, release agent and stir at high speed, mix into a premix, Extrude, modify and granulate with a twin-screw extruder, and use a horizontal film-drawing machine to carry out film-drawing, cutting, packaging, field filming, and investigation of the degradation time and degradation efficiency of the modified material.

[0041] Using the same method as in Example 1, it was found that the induction period of the mulch film was 40 days, and cracks began to appear on the 40th day after film covering, and reached a grade 3 degradation degree at 60 days of film covering, and large cracks of 50 cm appeared in the film film du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com