A method for producing butyric acid from corn cob full components

A technology for the production of butyric acid and corn cob, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of expensive and wasteful ionic liquids, and achieve the effect of realizing the utilization of all components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

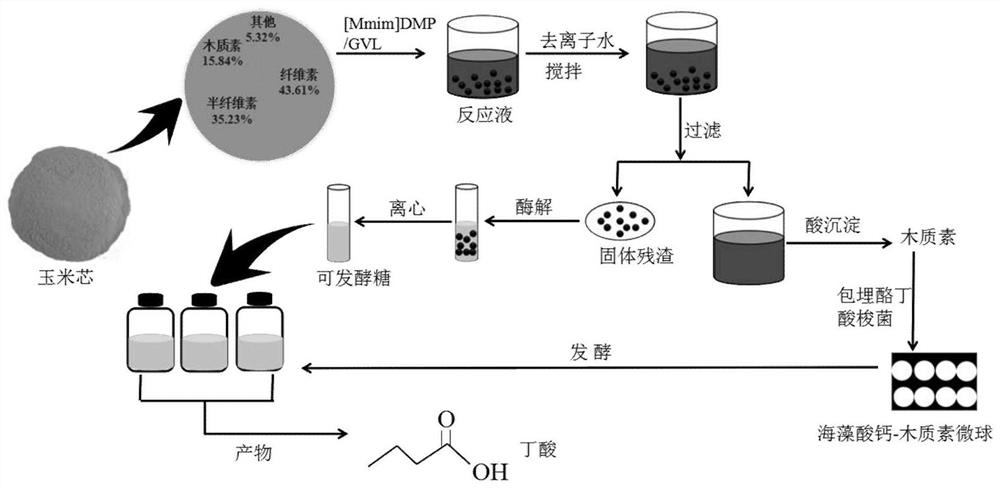

[0027] Such as figure 1 Shown, method of the present invention comprises the steps:

[0028] (1) Wash and dry the corncobs and crush them, with a particle size of 80-120 mesh;

[0029] (2) Preprocessing:

[0030] Take 0.3 g of corncob powder and add it to 5 mL [Mmim]DMP and 16 wt% γ-valerolactone mixture (16 wt% refers to the mass of γ-valerolactone / ([Mmim]DMP+γ-valerolactone total mass)), heated at 90°C in a 50 mL three-neck round bottom flask under nitrogen atmosphere, and reacted for 4 h under magnetic stirring at 1000 rpm. After the reaction was finished, the reaction mixture was diluted with the same volume of deionized water, which was used as an anti-solvent to precipitate the pretreated corncob powder. The resulting corncob residue and filtrate were separated by suction filtration.

[0031] (3) The corncob residue was repeatedly washed with deionized water to remove possible [Mmim]DMP and γ-valerolactone residues, and dried at 65°C for 10 hours to obtain the pretre...

Embodiment 2

[0039] (1) Wash and dry the corncobs and crush them, with a particle size of 80-120 mesh;

[0040] (2) Preprocessing:

[0041] Take 0.3 g of corncob powder, add it to 10 mL [Mmim]DMP and 14 wt % γ-valerolactone mixture, heat in a 50 mL three-necked round bottom flask at 90 °C under nitrogen atmosphere, and react under 1000 rpm magnetic stirring 3 h. After the reaction was finished, the reaction mixture was diluted with the same volume of deionized water, which was used as an anti-solvent to precipitate the pretreated corncob powder. The resulting corncob residue and filtrate were separated by suction filtration.

[0042] (3) The corncob residue was repeatedly washed with deionized water to remove possible [Mmim]DMP and γ-valerolactone residues, and dried at 65°C for 10 hours to obtain the pretreated corncob powder.

[0043] Put 0.25 g of pretreated corncob powder into a 25 mL Erlenmeyer flask, add 5 mL of 50 mM acetate buffer (pH4.8), 45 FPU / g cellulase (purchased from Ning...

Embodiment 3

[0050] (1) Wash and dry the corncobs and crush them, with a particle size of 80-120 mesh;

[0051] (2) Preprocessing:

[0052] Take 0.3 g corncob powder, add it to 15 mL [Mmim]DMP and 10 wt % γ-valerolactone mixture, heat in a 50 mL three-neck round bottom flask at 110 °C under nitrogen atmosphere, and react under 1000 rpm magnetic stirring 3 h. After the reaction was finished, the reaction mixture was diluted with the same volume of deionized water, which was used as an anti-solvent to precipitate the pretreated corncob powder. The resulting corncob residue and filtrate were separated by suction filtration.

[0053] (3) The corncob residue was repeatedly washed with deionized water to remove possible [Mmim]DMP and γ-valerolactone residues, and dried at 65°C for 10 hours to obtain the pretreated corncob powder.

[0054] Put 0.25 g of pretreated corncob powder into a 25 mL Erlenmeyer flask, add 5 mL of 50 mM acetate buffer (pH4.8), 45 FPU / g cellulase (purchased from Ningxia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com