Method for preparing xylooligosaccharide from biomass raw material and application of xylooligosaccharide in preparation of feed additive

A technology of biomass raw materials and feed additives, applied in the preparation of sugar derivatives, oligosaccharides, animal feed, etc., can solve the problems of preparation of feed grade xylooligosaccharides, long production cycle, large amount of reagents, etc., and achieve palatability Improvement, short production cycle, and the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

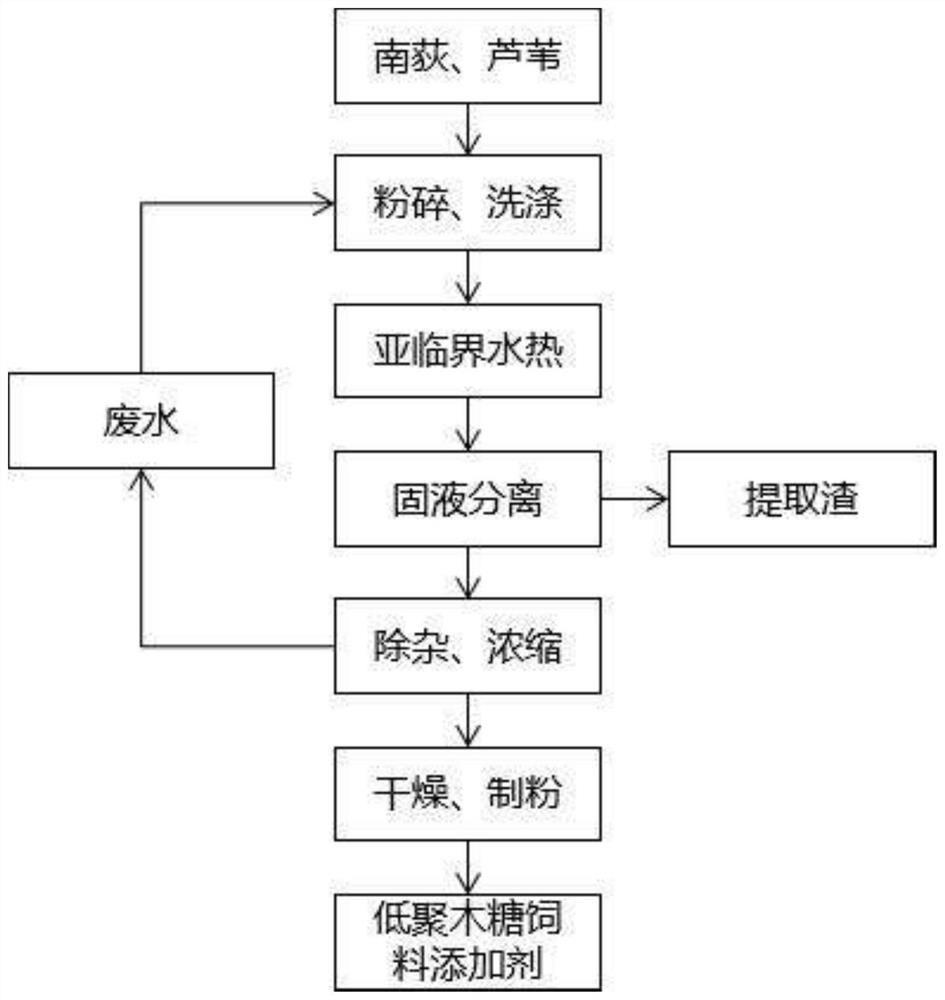

[0056] Embodiment 1 A kind of method of utilizing Nandi to prepare xylo-oligosaccharides and its application in the preparation of feed additives

[0057] 1. Raw materials used:

[0058] Nandi biomass with moisture content less than 0.001wt% and component content of glucan 35.6wt%, xylan 20.3wt%, arabinan 2.5wt%, lignin 25.5wt%, ash 3.5wt% and impurity balance .

[0059] 2. Preparation method

[0060] like figure 1 As shown, 1.5kg of Nandi biomass was pulverized to a 5-mesh sieve, mixed in a ratio of 1 g (Nandi biomass powder): 10 mL (deionized water) and added to a 25L autoclave, heated at 190° C., stirring 10min at 700rpm.

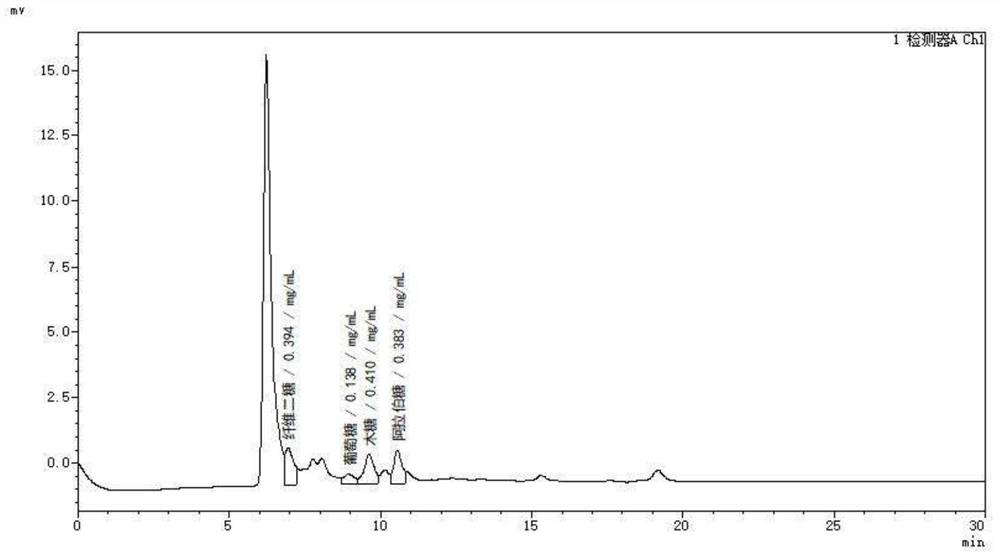

[0061] After the reaction was finished, it was cooled with water quickly to ensure that the reaction system was cooled to room temperature within 30 min, and 12.7 L of the hydrolysis mixed solution was obtained by solid-liquid separation of the pressure filtration equipment; Filtration and impurity removal were carried out, followed by interception ...

Embodiment 2

[0075] Embodiment 2 A kind of method of utilizing reed to prepare xylo-oligosaccharide and its application in preparing feed additive

[0076] 1. Raw materials used:

[0077] Reed biomass with moisture content less than 0.001wt% and component content of glucan 37.8wt%, xylan 18.0wt%, arabinan 1.2wt%, lignin 26.2wt%, ash 5.1wt% and impurity balance .

[0078] 2. Preparation method

[0079] The 1.5kg reed biomass is pulverized to a 5 mesh sieve, mixed with a ratio of 1g (reed biomass powder): 10mL (deionized water), and added to a 25L autoclave, heated to 190° C., at a stirring speed of 700rpm Condition for 10min.

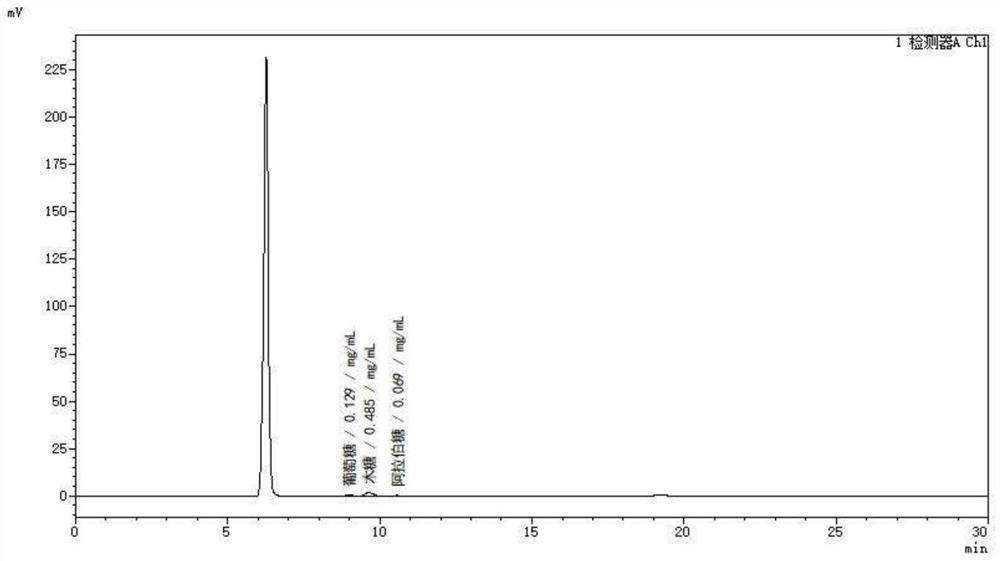

[0080] After the reaction was completed, the water was quickly cooled to ensure that the reaction system was cooled to room temperature within 30 min, and 12.6 L of the hydrolysis mixed solution was obtained by solid-liquid separation of the pressure filtration equipment; Filtration and impurity removal were carried out, followed by interception and concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com