Composite coating on aluminum workpiece surface and application thereof

A composite coating and workpiece surface technology, applied in the direction of surface reaction electrolytic coating, coating, metal material coating process, etc., can solve problems such as failure of lubricating layer, achieve small friction coefficient, reduce roughness, and strong binding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

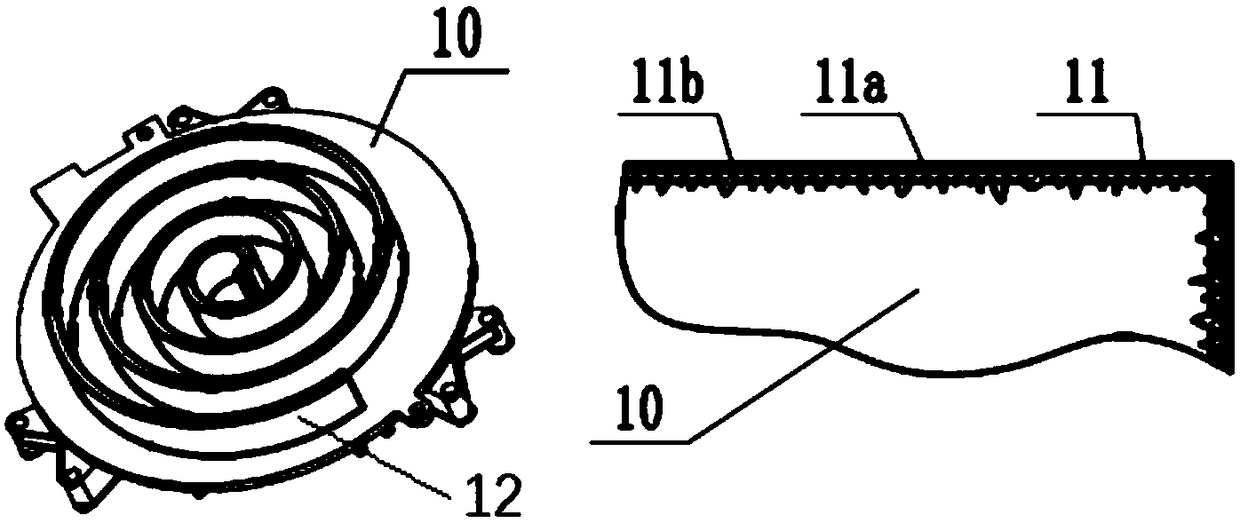

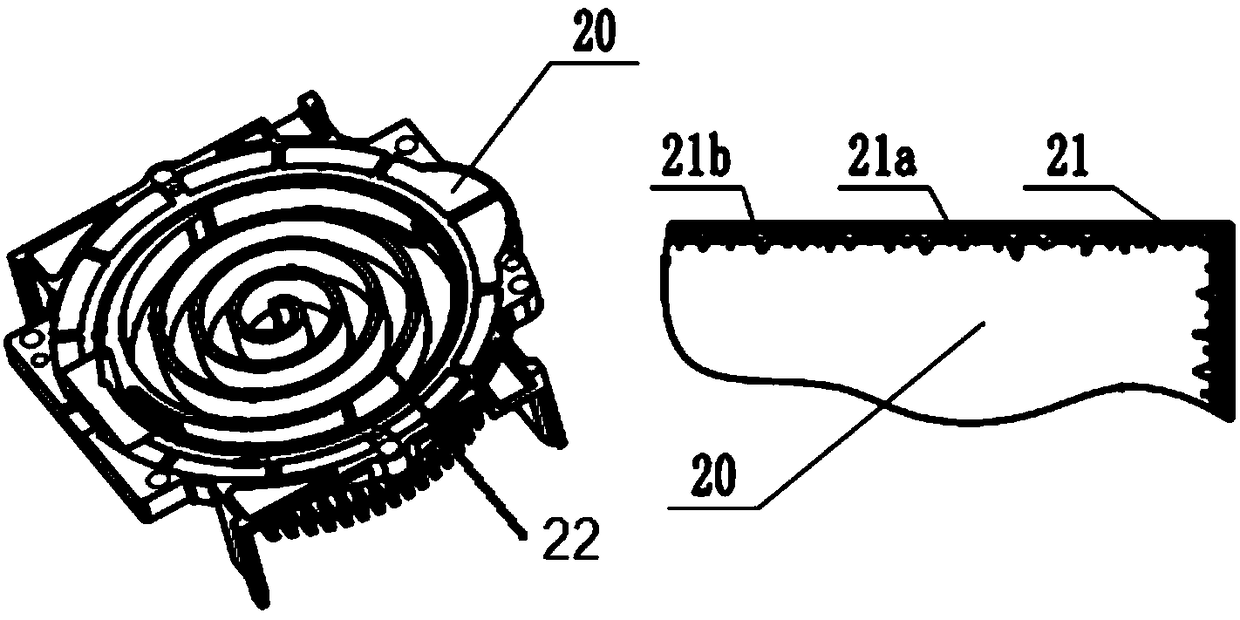

[0031] Such as figure 1 As shown, on the entire surface of the movable scroll 10 and the fixed scroll 20, Al 2 o 3 Ceramic-based hard wear-resistant layer (11a, 21a), the Al 2 o 3 The ceramic-based hard wear-resistant layer (11a, 21a) can be obtained by a hard anodic oxidation process or a micro-arc oxidation process. In this embodiment, hard anodizing is used to treat the surfaces of the movable scroll 10 and the fixed scroll 20 . The hard anodizing process complies with "GB / T 19822-2005 Specification for Hard Anodic Oxidation Films on Aluminum and Aluminum Alloys". The thickness of the hard anodized film layer measured by a thickness gauge is 35 μm. According to the test method described in "GB / T 4340.1 Metal Material Vickers Hardness Test Part 1: Test Method", a plurality of test points on the hard anodized layer are subjected to a Vickers microhardness test, and the measured The Vickers microhardness of the hard anodized layer is between 300HV-500HV, which is greatly...

Embodiment 2

[0037] There are also parts such as Oldham slip rings, upper brackets, pistons, cylinders, rollers or flanges in scroll compressors, and the composite coating of the present invention can also be arranged on the above parts. Hard anodizing or micro-arc oxidation can be used to set Al on the surface of the component 2 o 3 Ceramic-based hard wear-resistant layer. In this embodiment, micro-arc oxidation is carried out on the surface of the above-mentioned parts. The thickness of the micro-arc oxidation layer is 5-30 μm. In this embodiment, the thickness of the oxide layer on the surface of the above-mentioned parts is 15 μm. Between 700HV-1500HV, the hardness of the aluminum alloy base material is greatly improved, and the surface roughness of the micro-arc oxidation layer is Ra≤0.8μm, thereby improving the wear resistance of the air compressor scroll.

[0038] A tungsten disulfide layer is arranged on the micro-arc oxidation layer, and the coating method of the tungsten disulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com