Visual three-temperature-area gallium selenide single crystal growth device and method

A growth device and gallium selenide technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low transmittance, uneven stress distribution of gallium selenide single crystal, etc., and achieve uniform and compact turn spacing , Good optical uniformity, improving the effect of uneven stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

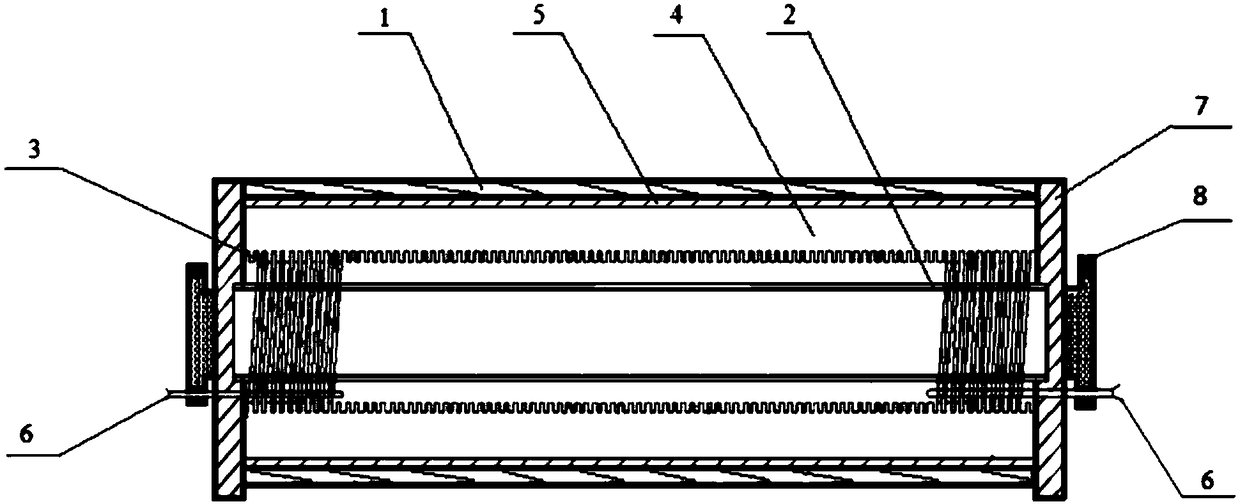

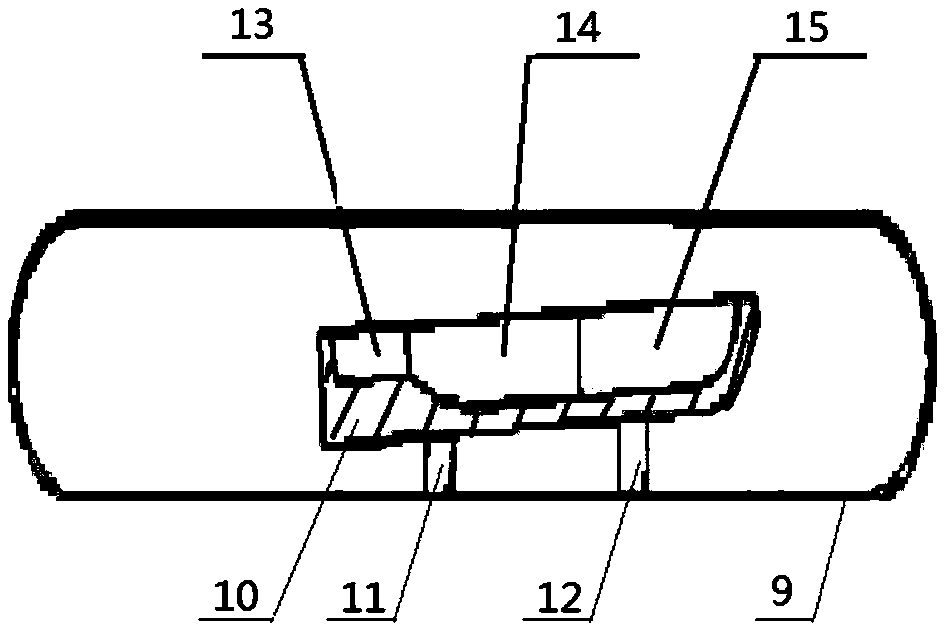

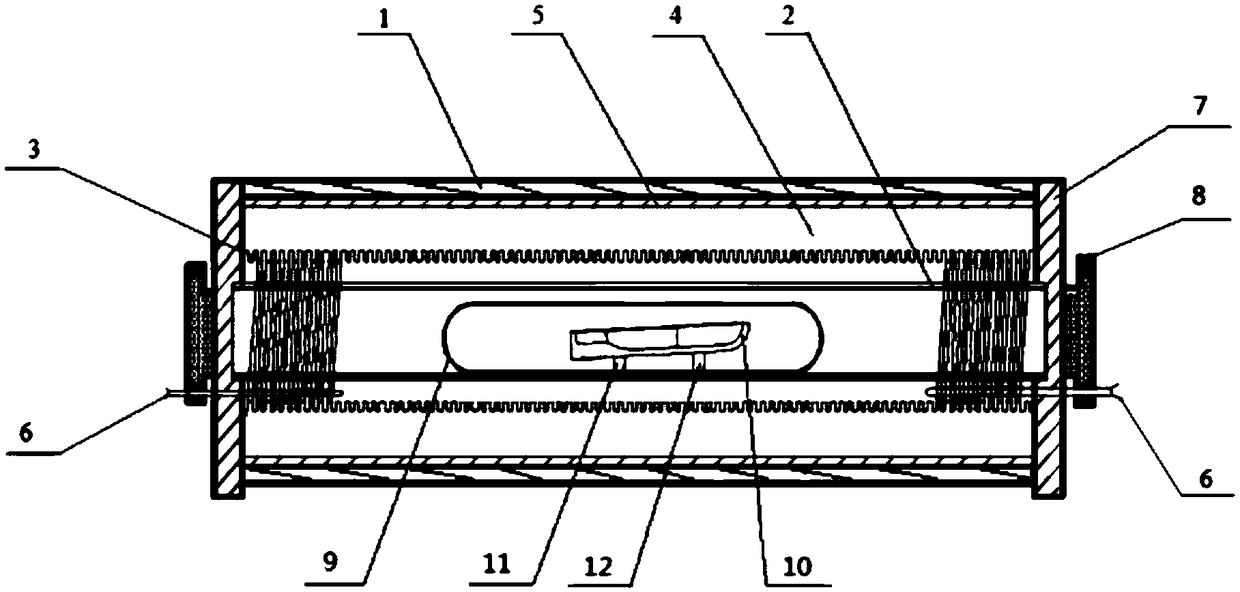

[0023] Specific Embodiment 1: The visible three-temperature-zone gallium selenide single crystal growth device of this embodiment includes an outer sleeve 1, an inner sleeve 2, a heating resistance wire 3, an annular cavity 4, a reflective film 5, and a temperature-measuring thermocouple 6 , end cap 7 and insulation plug 8;

[0024] Wherein the reflective film 5 is attached to the inner wall of the outer sleeve 1;

[0025] The inner sleeve 2 is placed in the outer sleeve 1, the area between the outer sleeve 1 and the inner sleeve 2 is an annular cavity 4, the heating resistance wire 3 is arranged in the annular cavity 4, and the end caps 7 are arranged at both ends of the annular cavity ; The heating resistance wire 3 is divided into three groups, and the temperature measuring thermocouple 6 is set in the area controlled by each group of heating resistance wire;

[0026] Insulation plugs 8 are arranged at both ends of the inner sleeve;

[0027] The material of the outer slee...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that the material of the outer sleeve 1 and the inner sleeve 2 is quartz; the others are the same as Embodiment 1.

[0030] In this embodiment, the outer sleeve 1 and the inner sleeve 2 are made of high-strength quartz glass, which can meet the requirement of visualization.

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the reflective film 5 is a gold film coated on the inner wall of the outer sleeve 1, and the thickness of the gold film is 5-20nm; the other is the same as the specific embodiment one or two .

[0032] In this embodiment, the gold film is used as the reflective film, which can improve the utilization rate of heat radiation in the outer sleeve 1, reduce heat loss, and realize the heat preservation effect of the growth device; at the same time, the gold film within this thickness range is transparent, which can realize the crystal growth process real-time perspective observation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com