Semicoke-based activated coke and preparation method thereof

A technology based on activated carbon and semi-coke, which is applied in the field of comprehensive utilization of resources, can solve the problems of high production cost, carbonization, long activation time, and large energy consumption of activated coke, and achieve the effects of shortening activation time, low cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

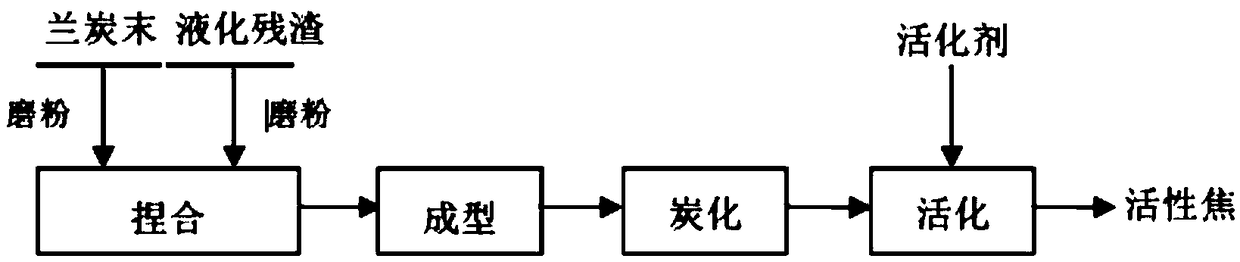

[0032] refer to figure 1 , the preparation method of blue carbon-based activated coke of the present invention comprises the following steps:

[0033] (1) Prepare raw materials: mix hydrofluoric acid and coal direct liquefaction residue at a mass ratio of 1: (4-10) for ash removal pretreatment; coal direct liquefaction residue is pretreated and crushed to 80-120 mesh and Put it in an oven for drying; crush the semi-coke powder to 80-120 mesh and put it in the oven for drying; the drying temperature of the coal direct liquefaction residue and the semi-coke powder is 105°C-120°C, and the drying time 4h-6h;

[0034] (2) Mix the semi-coke powder and the pretreated coal direct liquefaction residue according to the mass ratio (3:2)-(4:1) at room temperature, and add a starch solution with a solute mass fraction of 3%-6% And stir evenly, the added starch solution is used to knead semi-coke powder and coal direct liquefaction residue to form mixture A;

[0035] (3) Weigh 0.6-1.0 g ...

Embodiment 1

[0042]Weigh 100g of coal direct liquefaction residue, mix hydrofluoric acid and coal direct liquefaction residue at a mass ratio of 1:4 for deashing treatment, then dry at 105°C for 4 hours, and pulverize semi-coke powder and coal direct liquefaction residue to 80-120 mesh, blue coke powder and coal direct liquefaction residue after deashing are mixed at room temperature at a mass ratio of 4:1, and starch solution with a solute mass fraction of 3%-6% is added and stirred evenly, and the mixture is batched Under the pressure of 5MPa, it is pressed into a cylindrical material strip, and dried in an oven at 100°C for 4 hours. Take 15-20 dried shaped strips and put them into a carbonization activation furnace. The heating rate was raised to 500°C, the temperature was kept constant for 45 minutes, and then the temperature was continued to rise to 750°C under the protection of an inert gas. The flow rate of the activator was 80mL / min, and the activation time was 60 minutes. The compr...

Embodiment 2

[0044] Weigh 100g of coal direct liquefaction residue, mix hydrofluoric acid and coal direct liquefaction residue at a mass ratio of 1:5 for deashing treatment, then dry at 110°C for 5 hours, and pulverize semi-coke powder and coal direct liquefaction residue to 80 -120 mesh, semi-coke powder and coal direct liquefaction residue after deashing are mixed at room temperature in a mass ratio of 7:3, and starch solution with a solute mass fraction of 3%-6% is added and stirred evenly. Press it into a cylindrical strip under a pressure of 6MPa, and dry it in an oven at 110°C for 5 hours. Take 15-20 dried strips and put them into a carbonization activation furnace. Raise the temperature to 550°C, keep the temperature constant for 30min, then continue to heat up to 850°C under the protection of inert gas, the flow rate of the activator is 60mL / min, and the activation time is 90min. The compressive strength of the obtained active coke is 408.6N, and the iodine adsorption value is 343mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com