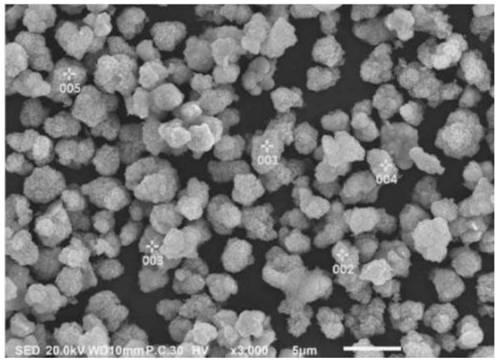

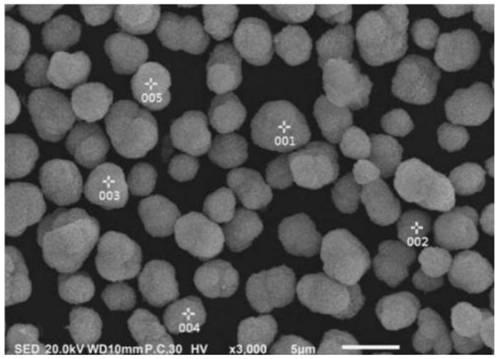

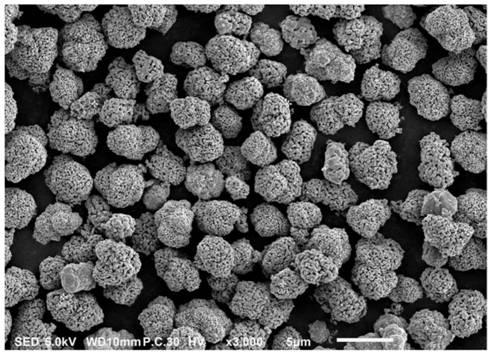

Aluminum-doped small particle spherical tricobalt tetroxide and preparation method thereof

A technology of cobalt tetroxide and small particles, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of poor cycle performance, uneven distribution of doping elements, and low tap density of lithium-ion batteries, and achieve good stability and electrochemical performance. Performance, simple process flow, high tap density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing intermittent aluminum-doped small particle spherical tricobalt tetroxide, comprising the following steps:

[0026] S1, prepare metal solution and precipitant solvent respectively:

[0027] Water is used to dissolve the cobalt source and the aluminum source respectively, and then the cobalt source solution and the aluminum source solution are mixed to obtain a metal solution containing aluminum and cobalt. The cobalt source and the aluminum source are firstly dissolved to obtain a solution, which is more conducive to the uniform mixing of the cobalt source and the aluminum source, and then ensures that the prepared tricobalt tetroxide element is evenly distributed, has good sphericity, and improves its performance.

[0028] Further, the mass ratio of cobalt to aluminum in the metal solution is 100:0.01-2.5. Adopting the above-mentioned mass ratio of cobalt and aluminum in the metal solution can ensure that the content of cobalt and aluminum in the...

Embodiment 1

[0048] This embodiment provides a batch-type preparation method of aluminum-doped small particle spherical tricobalt tetroxide, comprising the following steps:

[0049] S1, prepare metal solution and precipitant solvent respectively:

[0050] Use deionized water to dissolve aluminum sulfate and cobalt chloride respectively, then mix aluminum sulfate solution and cobalt chloride solution to obtain a metal solution containing aluminum and cobalt, and the cobalt ion and aluminum ion in the metal solution are 100g / L and 0.68g respectively / L. Ammonium bicarbonate was dissolved in deionized water so that the concentration of the precipitant solution was 230 g / L.

[0051] S2, crystallization reaction;

[0052] at 10m 3 Add 500L ammonium bicarbonate solution into the reaction kettle, then heat up to 46°C and mix the metal solution and the precipitant solution in parallel flow. The flow rate of the metal solution is 400L / h, and the flow rate of the precipitant solution is 560L / h. S...

Embodiment 2-6

[0057] The batch-type aluminum-doped small-particle spherical cobalt tetroxide preparation method provided in Examples 2-6 is basically the same as the batch-aluminum-doped small-particle spherical cobalt tetroxide preparation method provided in Example 1. The difference is that the specific operating conditions change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com