Resource treatment method of wood pulp black liquor obtained by sulfate method

A technology of sulfate method and disposal method, applied in chemical instruments and methods, water/sewage treatment, processing wastewater treatment, etc., can solve problems such as lignin resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

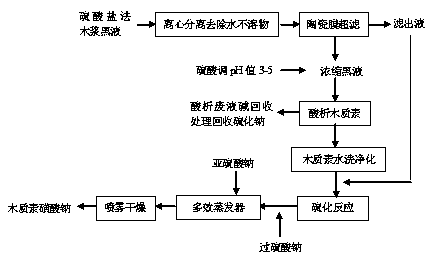

Method used

Image

Examples

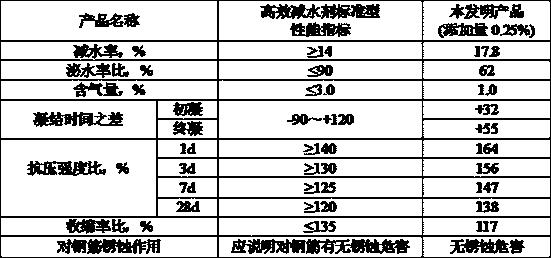

Embodiment 1

[0014] Kraft pulping black liquor with a solid content of 10%: .Add 20kg of cationic polyacrylamide aqueous solution with a mass fraction of 0.1% per 1000kg of pulping black liquor, mix and react, and centrifuge to remove water-insoluble matter; .At a temperature of 75°C, use a ceramic ultrafiltration membrane with a filter pore size of 10 nm to filter and concentrate the pulping black liquor to a solid content of 20%, and collect the filtrate for use. (3) Adjust the pH value of the concentrated black liquor to 3 with sulfuric acid, and centrifuge to obtain acid-analyzed lignin. The acid analysis waste liquid is treated with an alkali recovery process to recover sodium sulfide, and is reused for cooking and pulping; (4), acid analysis lignin is washed and purified, mixed with the filtrate of step (2), and reacted at 90 ° C for 1 hour; . Add sodium persulfate, evaporate and concentrate in a multi-effect evaporator, add sodium sulfite after the first effect of evaporation, a...

Embodiment 2

[0016] Kraft pulping black liquor with a solid content of 15%: .Add 30kg of anionic polyacrylamide aqueous solution with a mass fraction of 0.2% to every 1000kg of pulping black liquor, mix and react, and centrifuge to remove water-insoluble matter; .At a temperature of 85°C, use a ceramic ultrafiltration membrane with a filter pore size of 10 nm to filter and concentrate the pulping black liquor to a solid content of 30%, and collect the filtrate for use. (3) Adjust the pH value of the concentrated black liquor to 4 with sulfuric acid, and centrifuge to obtain acid-analyzed lignin. The acid analysis waste liquid is treated with an alkali recovery process to recover sodium sulfide, and is reused for cooking and pulping; (4), acid analysis lignin is washed and purified, mixed with the filtrate of step (2), and reacted at 95 ° C for 1 hour; . Add sodium persulfate, evaporate and concentrate in a multi-effect evaporator, add sodium sulfite after the first effect of evaporatio...

Embodiment 3

[0018] Kraft pulping black liquor with a solid content of 20%: .Add 40kg of cationic polyacrylamide aqueous solution with a mass fraction of 0.2% to every 1000kg of pulping black liquor, mix and react, and centrifuge to remove water-insoluble matter; .At a temperature of 90°C, use a ceramic ultrafiltration membrane with a filter pore size of 20 nm to filter and concentrate the pulping black liquor to a solid content of 30%, and collect the filtrate for use. (3) Adjust the pH value of the concentrated black liquor to 5 with sulfuric acid, and centrifuge to obtain acid-analyzed lignin. The acid analysis waste liquid is treated with an alkali recovery process to recover sodium sulfide, and is reused for cooking and pulping; (4), acid analysis lignin is washed and purified, mixed with the filtrate of step (2), and reacted at 98 ° C for 1 hour; . Add sodium persulfate, evaporate and concentrate in a multi-effect evaporator, add sodium sulfite after the first effect of evaporati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com